Halogen-free flame-retardant thermoplastic elastomer cable material for new energy vehicles

A thermoplastic elastomer, new energy vehicle technology, applied in the field of cable materials, can solve problems such as cable material aging, and achieve the effects of reducing water absorption, increasing compatibility, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

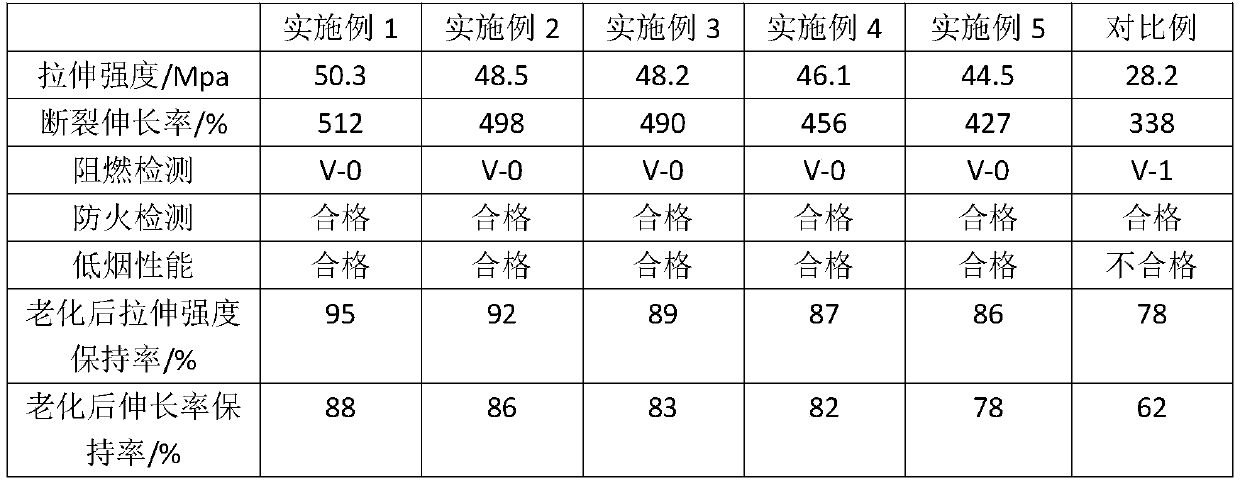

Examples

Embodiment 1

[0043] The present invention relates to a halogen-free flame-retardant thermoplastic elastomer cable material for new energy vehicles, and the weight parts of its raw materials are as follows:

[0044] Thermoplastic elastomer 35 parts

[0045] Polyolefin 20 parts

[0046] 10 parts polyphenylene ether

[0047] Halogen-free flame retardant 3 parts

[0048] Compatibilizer 3 parts

[0049] Antioxidant 3 parts

[0050] Filling oil 5 parts;

[0051] Preferably, the thermoplastic elastomer is synthesized by dynamic vulcanization of polyamide and butyl rubber, wherein polyamide accounts for 70% of the mass of the thermoplastic elastomer, butyl rubber accounts for 30% of the mass of the thermoplastic elastomer, and the Polyamide is a long carbon chain polyamide polymerized from dodecanediamine and dodecanedioic acid;

[0052] Preferably, the polyolefin is polyethylene resin;

[0053] Preferably, preferably, the halogen-free flame retardant is PDMS / chitosan-lignin-NCNTs;

[0054...

Embodiment 2

[0062] The present invention relates to a halogen-free flame-retardant thermoplastic elastomer cable material for new energy vehicles, and the weight parts of its raw materials are as follows:

[0063] 30 parts thermoplastic elastomer

[0064] Polyolefin 20 parts

[0065] 10 parts polyphenylene ether

[0066] Halogen-free flame retardant 3 parts

[0067] Compatibilizer 2 parts

[0068] Antioxidant 1 part

[0069] Filling oil 6 parts;

[0070] Preferably, the thermoplastic elastomer is synthesized by dynamic vulcanization of polyamide and butyl rubber, wherein polyamide accounts for 60% of the mass of the thermoplastic elastomer, and butyl rubber accounts for 40% of the mass of the thermoplastic elastomer, so The polyamide is a long carbon chain polyamide synthesized by tetradecanediamine and tetradecanedioic acid;

[0071] Preferably, the polyolefin is polypropylene resin;

[0072] Preferably, the halogen-free flame retardant is PDMS / chitosan-lignin-NCNTs;

[0073] Pre...

Embodiment 3

[0081] The present invention relates to a halogen-free flame-retardant thermoplastic elastomer cable material for new energy vehicles, and the weight parts of its raw materials are as follows:

[0082] Thermoplastic Elastomer 20 parts

[0083] Polyolefin 30 parts

[0084] 15 parts polyphenylene ether

[0085] Halogen-free flame retardant 2 parts

[0086] Compatibilizer 3 parts

[0087] Antioxidant 2 parts

[0088] 7 parts of filling oil;

[0089] Preferably, the thermoplastic elastomer is synthesized by dynamic vulcanization of polyamide and butyl rubber, wherein polyamide accounts for 50% of the mass of the thermoplastic elastomer, and butyl rubber accounts for 50% of the mass of the thermoplastic elastomer, so The polyamide is a long carbon chain polyamide polymerized by dodecanediamine and hexadecanedioic acid;

[0090] Preferably, the polyolefin is polyethylene resin;

[0091] Preferably, the halogen-free flame retardant is PDMS / chitosan-lignin-NCNTs;

[0092] Pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com