Solvent-free epoxy paint set and preparation method and application thereof

An epoxy coating and solvent-free technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve problems such as high viscosity, difficult construction, and loss of environmental protection of solvent-free epoxy coatings, so as to improve flexibility and improve Improvement of construction performance and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

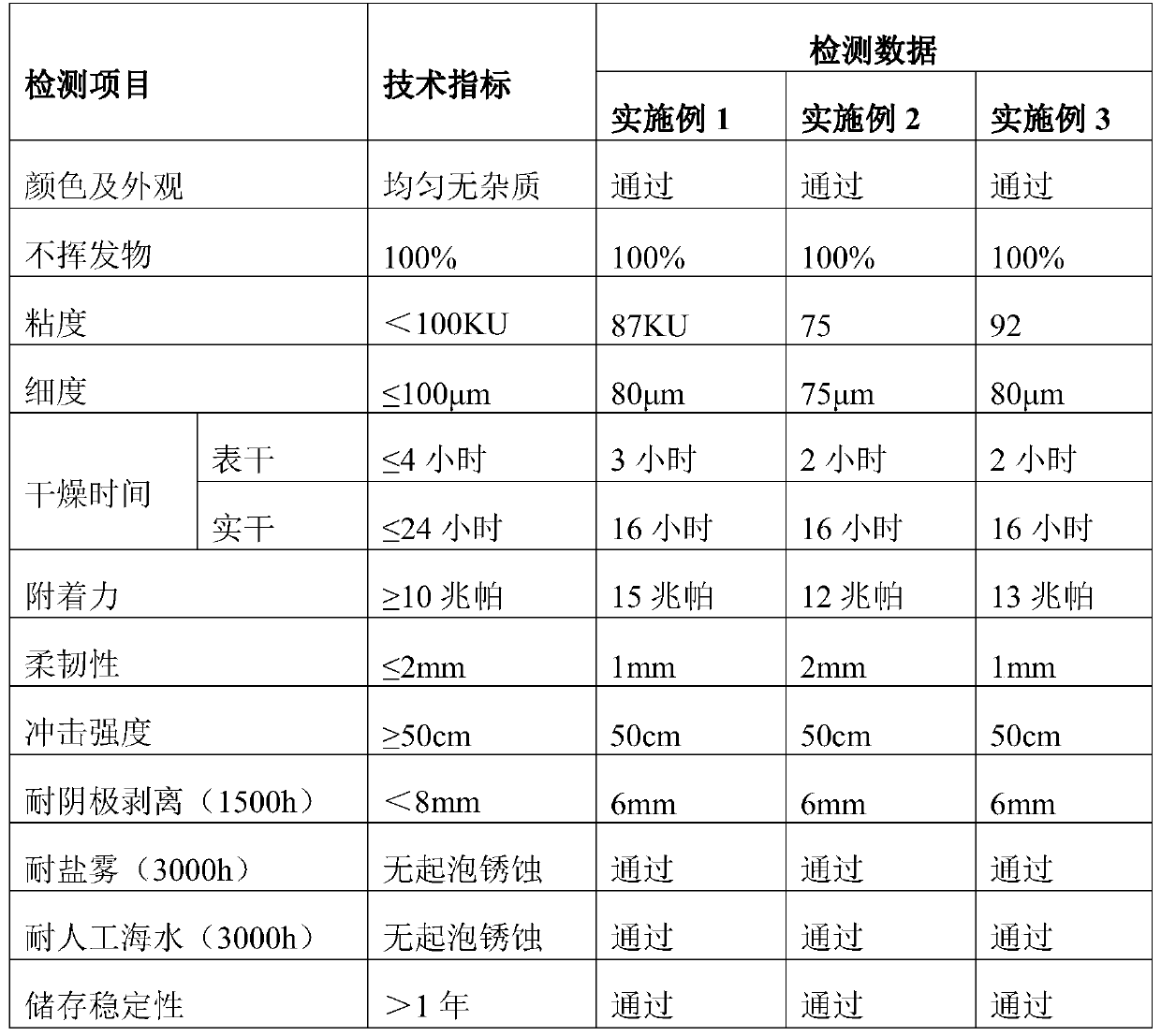

[0043] According to the method for preparing a solvent-free epoxy coating set according to the above-mentioned embodiments of the present invention, by using the above-mentioned raw materials together and further controlling the ratio of raw materials and preparation conditions, not only can the viscosity of the prepared coating be further reduced, but also can be further improved. The flexibility, impact resistance, adhesion and comprehensive anti-corrosion performance of the formed paint film, for example, in step (1), the resin and pigment can be more fully infiltrated by controlling the low-speed stirring time for not less than 4 hours, and the coated More perfect, it can not only fully reduce the viscosity, but also improve the compactness of the paint film. Among them, the solvent-free epoxy coating set prepared by the above method has an ultra-low viscosity after mixing, not more than 95KU, and the prepared solvent-free epoxy coating set has at least the following advant...

Embodiment 1

[0067] 1) Solvent Free Epoxy Paint Kit

[0068] This solvent-free epoxy coating kit consists of a first component and a second component in which:

[0069] The first component comprises the low-viscosity bisphenol A epoxy resin (EPIKOTE827) of 22 parts by weight, the hydrocarbon petroleum resin (Lü Tege C30) of 5 parts by weight, the cycloaliphatic epoxy resin of 22 parts by weight (Changzhou Jiafa JEW-12), the glycidyl neodecanoate of 5 parts by weight, the hyperdispersant Lubrizol 20000 of 1 part by weight, the polyamide wax anti-settling and anti-sagging agent 6650 of 1.5 parts by weight, the polyphosphorus molybdenum of 10.8 parts by weight Zinc, 12 parts by weight of barite, 15 parts by weight of mica powder, 5 parts by weight of aluminum powder, 0.5 parts by weight of silane coupling agent KH550, 0.2 parts by weight of organosilicon defoamer TEGAO900;

[0070] The second component includes: 65 parts by weight of modified fatty amine, 30 parts by weight of isophorone dia...

Embodiment 2

[0080] The difference with embodiment 1 is:

[0081] The first component comprises the low-viscosity bisphenol A epoxy resin (EPIKOTE827) of 20 parts by weight, the hydrocarbon petroleum resin (Lütege C30) of 10 parts by weight, the cycloaliphatic epoxy resin of 25 parts by weight (Changzhou Jiafa JEW-12), the glycidyl neodecanoate of 4 parts by weight, the hyperdispersant Lubrizol 20000 of 1.5 parts by weight, the polyamide wax anti-settling and anti-sagging agent 6650 of 0.5 parts by weight, the polyphosphorus molybdenum of 12 parts by weight Zinc, 15 parts by weight of barite, 17 parts by weight of mica powder, 6 parts by weight of aluminum powder, 0.5 parts by weight of silane coupling agent KH550, 0.8 parts by weight of organosilicon defoamer TEGAO900;

[0082] The second component includes: 50 parts by weight of modified fatty amine, 40 parts by weight of isophorone diamine and 10 parts by weight of modified amine DMP30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hard work time | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com