Embedment glue based on PBA embedment and zero-bubble embedment method

A glue and potting technology, which is applied in the direction of adhesives, epoxy glue, adhesive types, etc., can solve the problems of potting glue sealing performance, easy to generate air bubbles, unsatisfactory potting effect, etc., to achieve potting effect Good, avoid air bubbles, improve curing speed and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

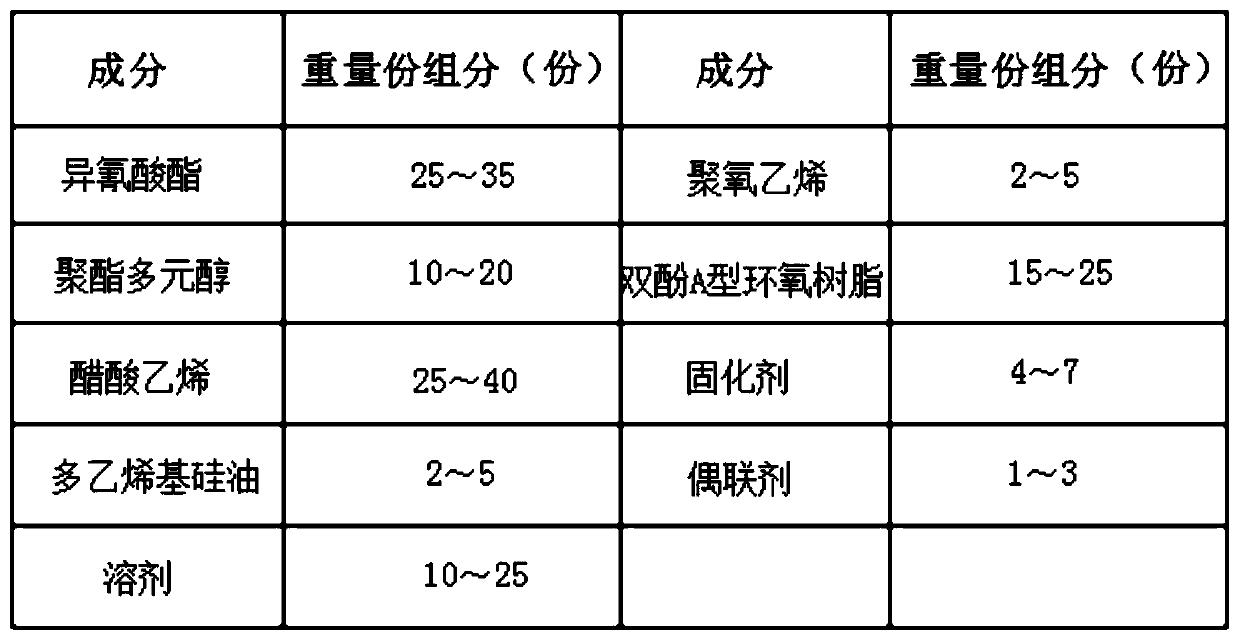

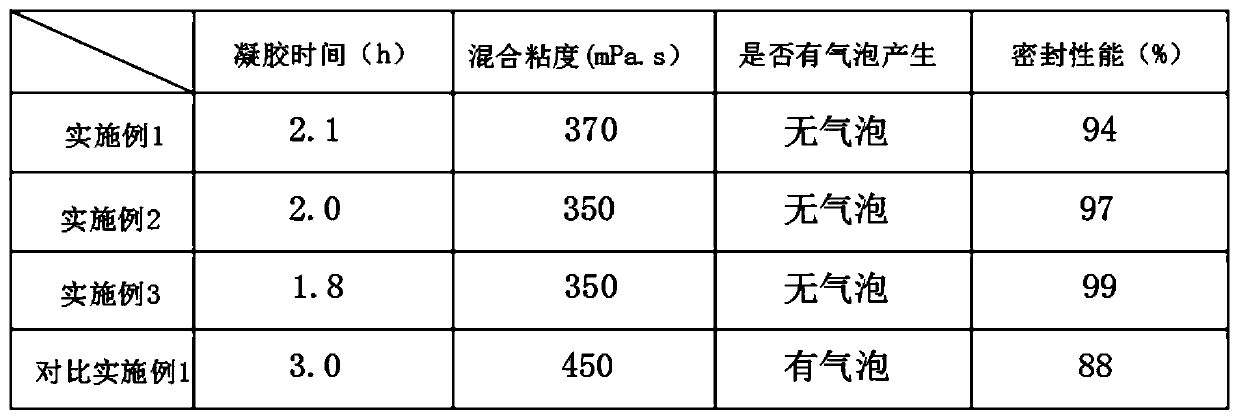

[0021] A potting glue based on PBA potting, the components of the potting glue are: 25 parts by weight of isocyanate, 10 parts of polyester polyol, 25 parts of vinyl acetate, 2 parts of polyvinyl silicone oil, and 4 parts of polyoxyethylene , 15 parts of bisphenol A epoxy resin, 4 parts of curing agent, 1 part of coupling agent, and 10 parts of solvent.

[0022] Wherein, the isocyanate is one or more of T-100, HDI, IPDI or hydrogenated MDI.

[0023] Among them, the polyester polyol is a polyester polyol with a functionality of 2.3 and a number average molecular weight in the range of 800-1500.

[0024] Further, the curing agent is a modified amine curing agent.

[0025] Still further, the solvent is one or more of toluene, ethyl acetate or DMF.

[0026] Still further, a kind of potting glue based on PBA potting and a zero-bubble potting method, the zero-bubble potting method is the following steps:

[0027] S1. Add isocyanate and polyester polyol into the vacuum reaction ta...

Embodiment 2

[0033] A potting glue based on PBA potting, the components of the potting glue are: 35 parts by weight of isocyanate, 20 parts of polyester polyol, 40 parts of vinyl acetate, 5 parts of polyvinyl silicone oil, and 8 parts of polyoxyethylene , 25 parts of bisphenol A epoxy resin, 7 parts of curing agent, 3 parts of coupling agent, and 25 parts of solvent.

[0034] Wherein, the isocyanate is one or more of T-100, HDI, IPDI or hydrogenated MDI.

[0035] Among them, the polyester polyol is a polyester polyol with a functionality of 2.3 and a number average molecular weight in the range of 800-1500.

[0036] Further, the curing agent is a modified amine curing agent.

[0037] Still further, the solvent is one or more of toluene, ethyl acetate or DMF.

[0038] Still further, a kind of potting glue based on PBA potting and a zero-bubble potting method, the zero-bubble potting method is the following steps:

[0039] S1. Add isocyanate and polyester polyol into the vacuum reaction t...

Embodiment 3

[0045] A potting glue based on PBA potting, the components of the potting glue are: 30 parts by weight of isocyanate, 15 parts of polyester polyol, 30 parts of vinyl acetate, 3 parts of polyvinyl silicone oil, and 6 parts of polyoxyethylene , 20 parts of bisphenol A epoxy resin, 6 parts of curing agent, 2 parts of coupling agent and 22 parts of solvent.

[0046] Wherein, the isocyanate is one or more of T-100, HDI, IPDI or hydrogenated MDI.

[0047] Among them, the polyester polyol is a polyester polyol with a functionality of 2.3 and a number average molecular weight in the range of 800-1500.

[0048]Further, the curing agent is a modified amine curing agent.

[0049] Still further, the solvent is one or more of toluene, ethyl acetate or DMF.

[0050] Still further, a kind of potting glue based on PBA potting and a zero-bubble potting method, the zero-bubble potting method is the following steps:

[0051] S1. Add isocyanate and polyester polyol into the vacuum reaction tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com