Laser lighting assembly using hollow alumina microspheres and manufacturing method thereof

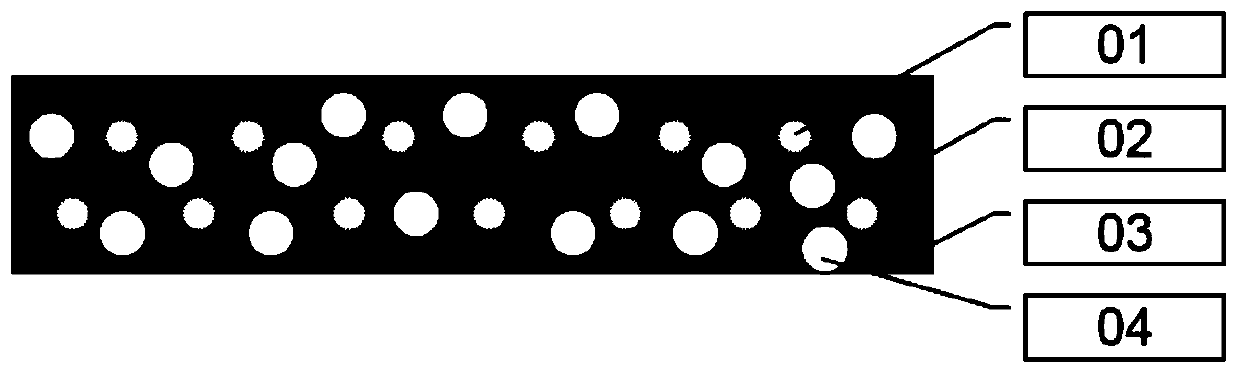

A hollow alumina and laser lighting technology, applied in the field of lighting, can solve the problems of fluorescent material heat dissipation and heat conduction performance reduction, reduce the light efficiency of laser lighting devices, heat conduction and laser spot uniformity, etc., achieve excellent scattering ability, uniform light spot, and manufacturing The effect of small process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The hollow alumina microspheres, Y 3 al 5 o 12 : Ce phosphor, low-melting glass powder and volatile organic compounds are uniformly mixed according to the mass ratio of 1:10:10:2. Then the above slurry was painted on the sapphire substrate, the thickness of the painting was 100 μm, and the thickness of the substrate was 1 mm. Then sinter the substrate carrying the slurry at high temperature, the sintering temperature is 600°C, and the sintering time is 30min. After the sample is cooled, the glass-like substance can be removed from the sapphire surface.

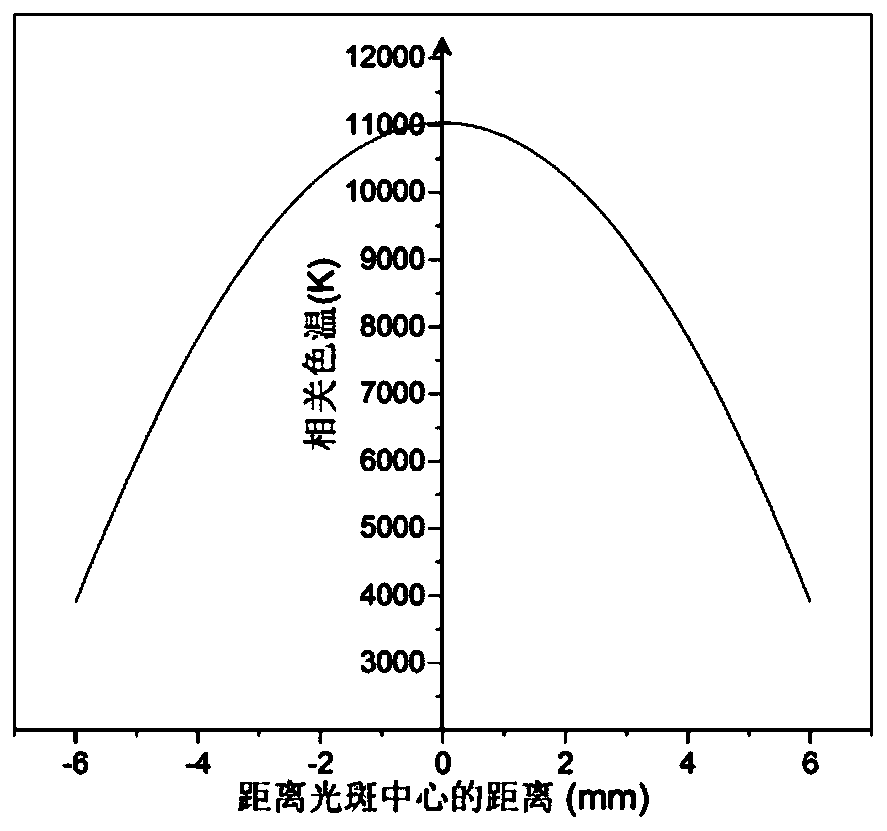

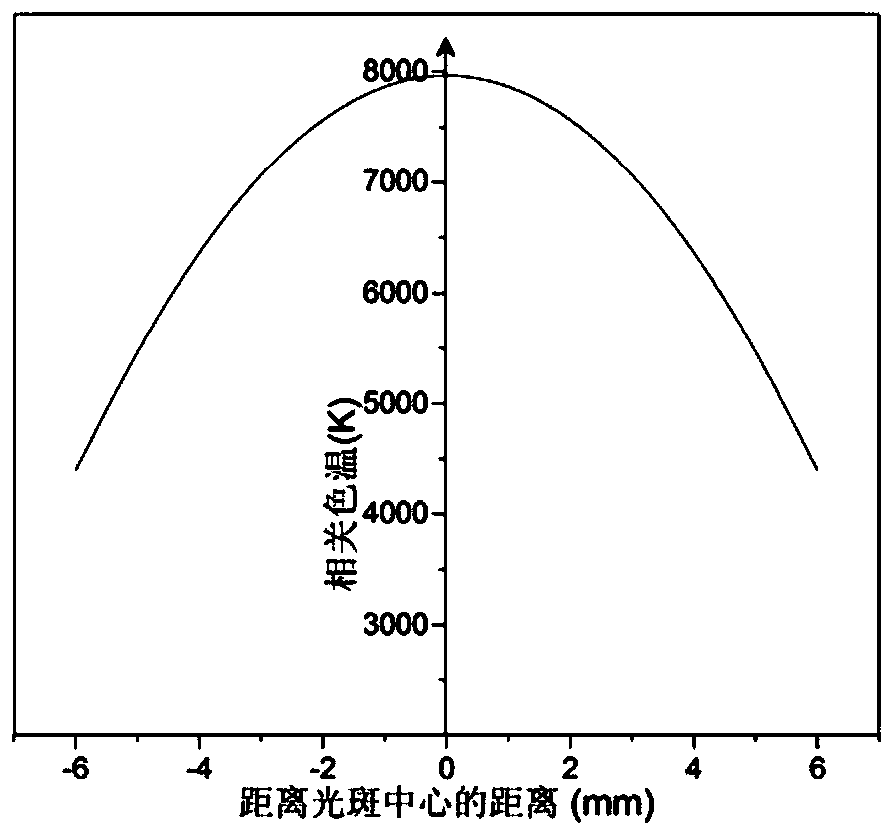

[0062] The device is irradiated with a blue laser with a power of 10 W and an emission wavelength of 450 nm, incident from the light-emitting layer. For the measurement results of spot uniformity, see Figure 4 . It can be seen that due to the existence of the structure (micropore) of hollow alumina microspheres, when the distance away from the center of the spot increases a lot, the correlated color temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com