Improved trough-type ozone treatment system for processing solar cell silicon wafer

An ozone treatment and solar cell technology, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of increasing labor and operating costs, unfavorable automation of the whole line, poor anti-PID effect, etc., to reduce labor costs and Production cost, increase the ease of use of the machine, and reduce the effect of design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

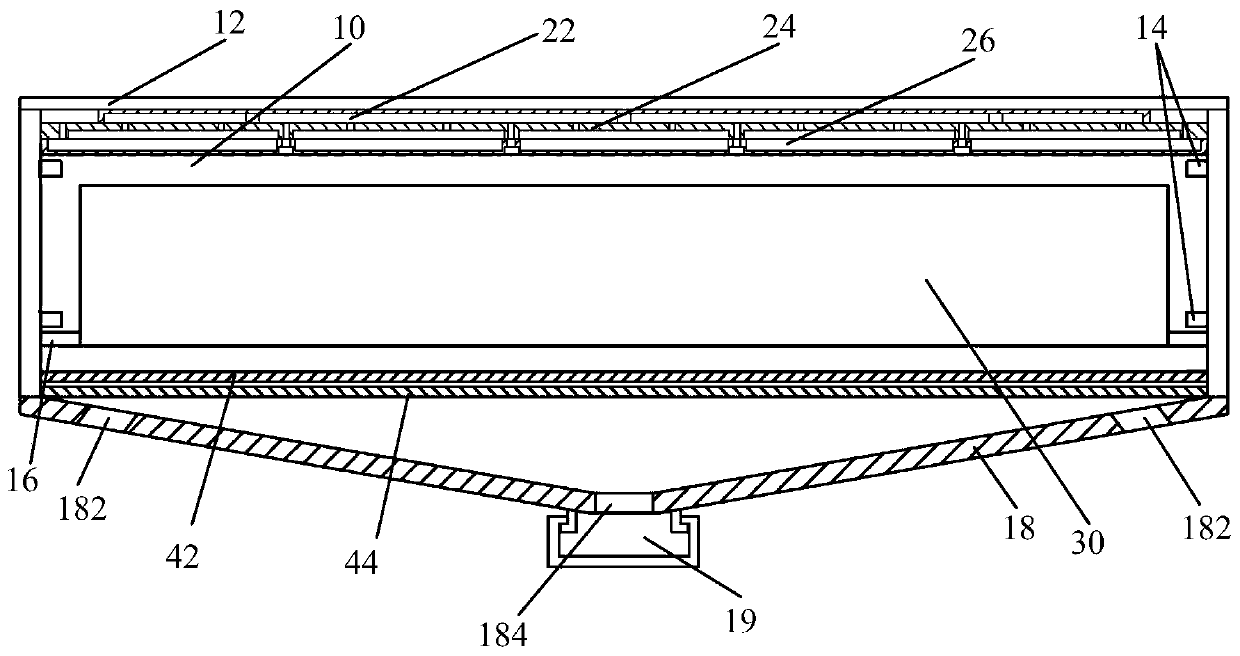

[0030] The structural features, working principles and advantages of the present invention are described in detail as follows in conjunction with the accompanying drawings.

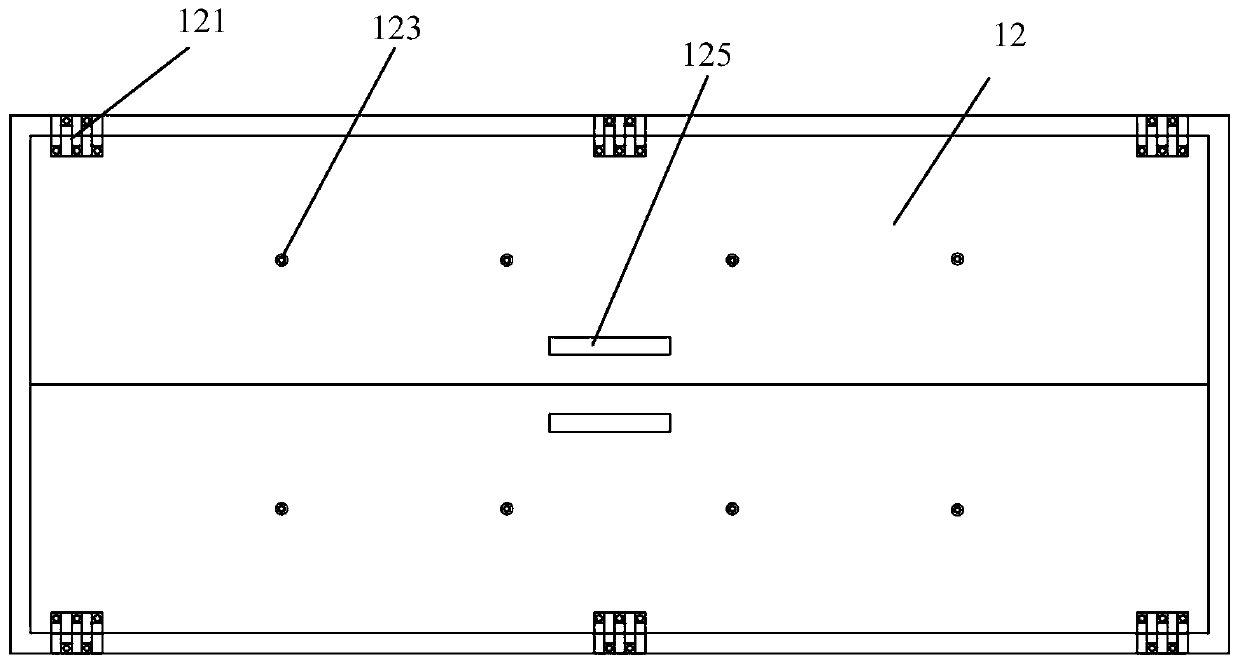

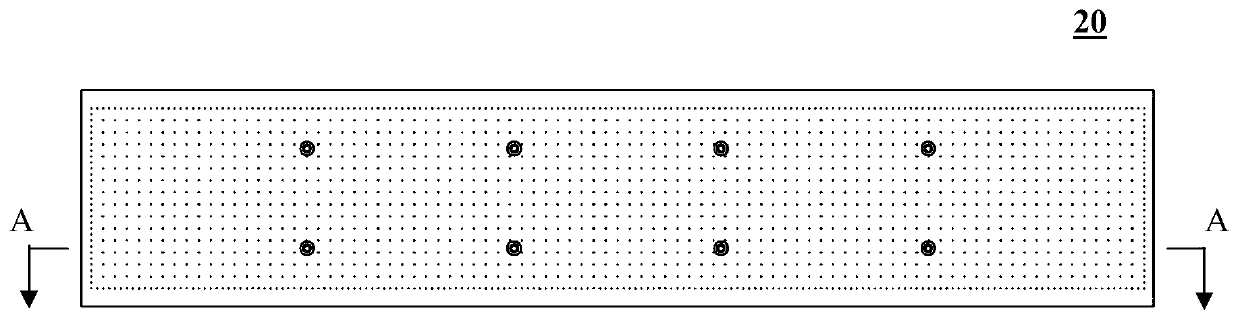

[0031] refer to figure 1 Shown is a schematic diagram of the composition of an improved trough ozone treatment system for solar cell silicon wafer processing according to an embodiment of the present invention. The trough ozone treatment system includes a tank body 10, a cover plate 12, and consists of three stages The ozone spray plate 20 formed by the air duct, the cover plate 12 and the spray plate 20 are fixed into an integral structure; the silicon chip loading flower basket 30 placed inside the tank body 10, and the fixing of the loading flower basket 30 placed in the tank body On the column 16; the ventilation system arranged under the loading flower basket 30, the ventilation system includes a first-level ventilation uniform plate 42, a secondary ventilation uniform flow plate 44, a funnel-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com