Tin-protecting PCB film-removing liquid

A film liquid and life-span technology, applied in the application of non-metallic protective layer, secondary treatment of printed circuit, photosensitive material processing, etc., can solve the problem of poor alkali resistance of tin layer, increase of tin plating and tin stripping cost, tin layer corrosion, etc. problems, to achieve the effect of improving processing capacity, improving film removal efficiency, and promoting tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Since the proportioning process of the present invention is the same as that of commonly used film removal solutions and is well known by those skilled in the art, it will not be described in detail.

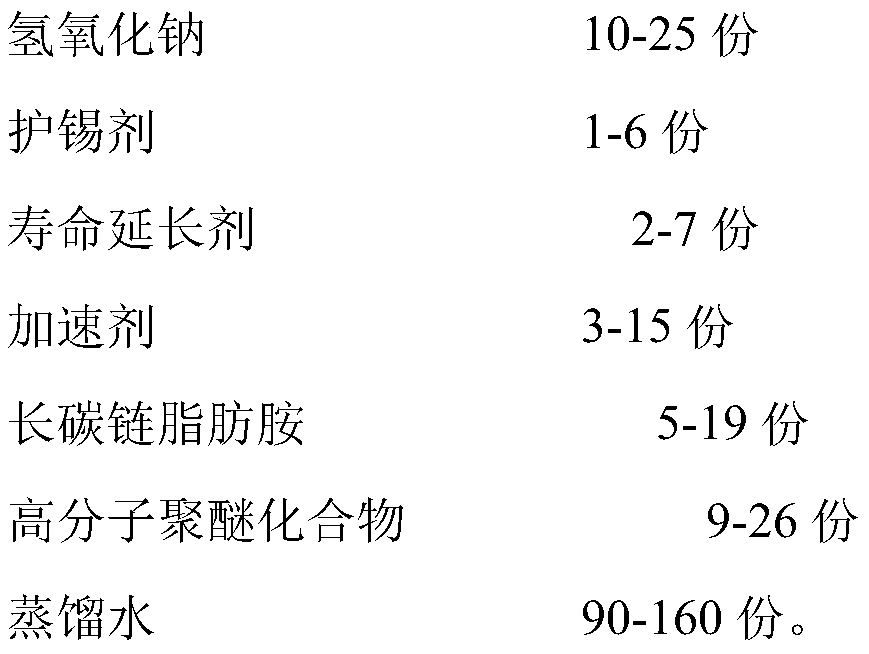

[0029] A tin protection type PCB film removal solution, comprising the following parts by weight:

[0030]

[0031]

[0032] Among them, the tin protecting agent is 10 parts of imidazole, 12 parts of alkyl imidazole, and 11 parts of benzotriazole.

[0033] The life extension agent is 16 parts of glycerin and 10 parts of isopropanol.

[0034] The accelerator is 12 parts of ethanolamine and 11 parts of triethanolamine.

[0035] The polymer polyether compound is propylene glycol block polyether with a molecular weight of 1000 and trimethylolpropane polyether with a molecular weight of 500, and the mixing ratio is 1:1 by weight.

Embodiment 2

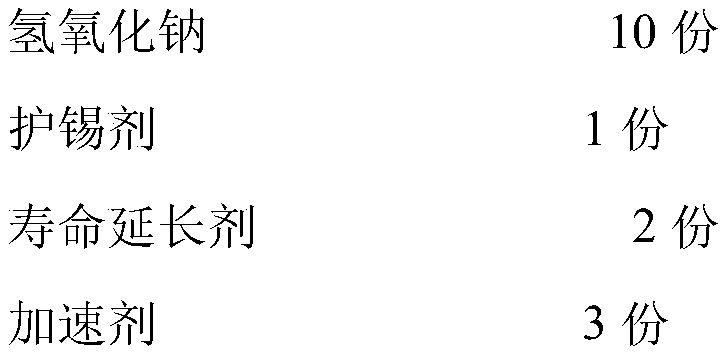

[0037] A tin protection type PCB film removal solution, comprising the following parts by weight:

[0038]

[0039] The tin protecting agent is 12 parts of imidazole, 9 parts of sodium citrate and 9 parts of urea.

[0040] The life extension agent is glycerin and polyethylene glycol with a molecular weight of 300.

[0041] The accelerator is 12 parts of ethanolamine and 11 parts of triethanolamine.

[0042] The polymer polyether compound is a propylene glycol block polyether with a molecular weight of 1200 and a trimethylolpropane polyether with a molecular weight of 700, and the mixing ratio is 1:1 by weight.

Embodiment 3

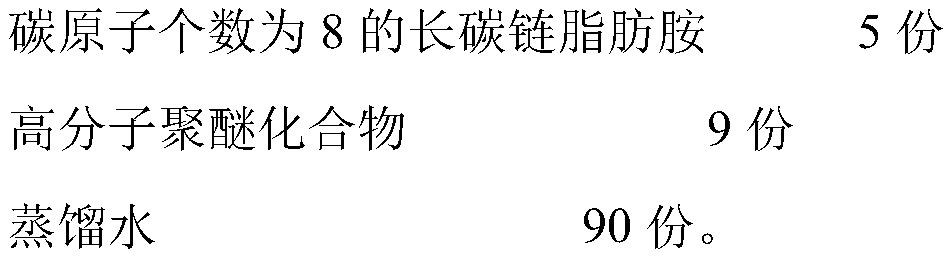

[0044] A tin protection type PCB film removal solution, comprising the following parts by weight:

[0045]

[0046]

[0047] Among them, the tin protecting agent is 13 parts of benzotriazole, 11 parts of sodium citrate, 9 parts of urea, and 11 parts of tetrahydrosugar alcohol.

[0048] The life extension agent is polyethylene glycol with 11 parts of isopropanol and a molecular weight of 400.

[0049] The accelerator is 14 parts of ethanolamine and 8 parts of ammonia water.

[0050] The polymer polyether compound is propylene glycol block polyether with a molecular weight of 1300 and trimethylolpropane polyether with a molecular weight of 800, and the mixing ratio is 1:1 by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com