Multifunctional non-burning type gas-permeable brick preparation method

A breathing brick and multi-functional technology, applied in the field of decorative materials, can solve problems such as high energy consumption, high pollution, and high emissions, and achieve the effects of reducing pollution, reducing energy consumption, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

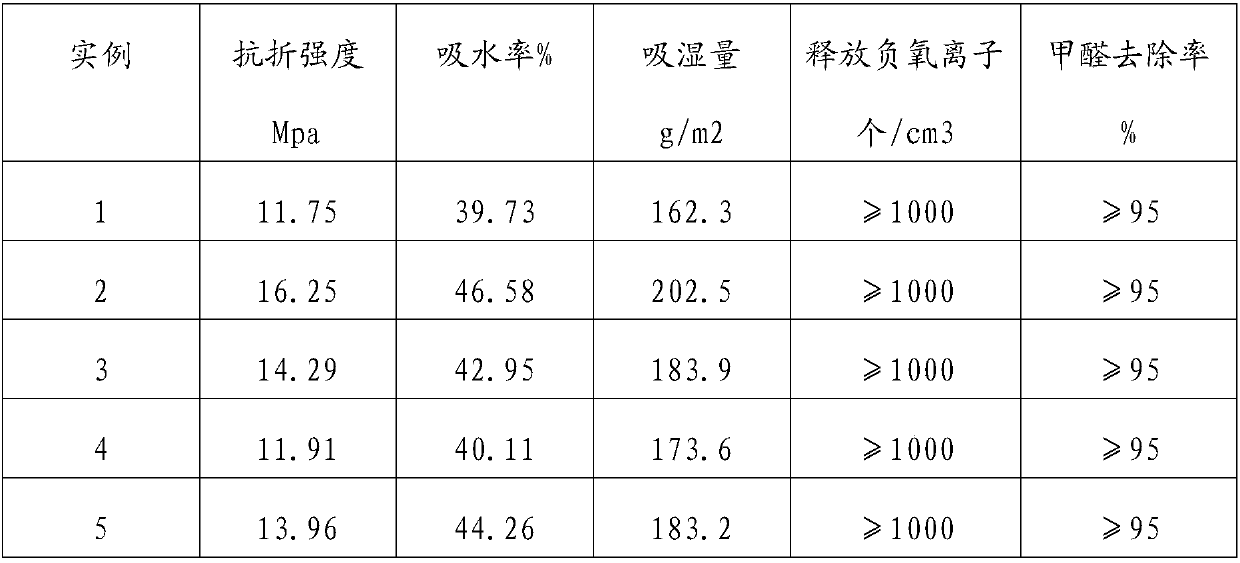

Examples

Embodiment 1

[0026] A kind of preparation method of multi-functional fire-free breathing brick, this method is to realize through following specific steps and technological conditions:

[0027] a) Mixing of blanks: according to the percentage by mass, take 49% of diatomite raw soil, 35% of white cement, 1% of silica fume, 5% of calcium hydroxide, and 10% of glass fiber, and mix them evenly for later use;

[0028] b) fabric mixing: according to the percentage by mass, take 60% of diatomite filter aid, 35% of white cement, and 5% of calcium hydroxide, and mix them evenly for later use;

[0029] c) Billet granulation: send the mixed billet into the granulator, and add 0.1% of calcium formate and 0.5% of ceramic reinforcing agent according to the percentage of billet mass, spray water, stir, extrude, crush, and sieve, Control the moisture content of the powder at 30%, and control the particle size between 8-16 mesh;

[0030] d) Fabric granulation: Send the mixed fabric into the granulator, an...

Embodiment 2

[0036] A kind of preparation method of multi-functional fire-free breathing brick, this method is to realize through following specific steps and technological conditions:

[0037] a) Billet mixing: According to the percentage by mass, take 43% of diatomite raw soil, 45% of white cement, 5% of silica fume, 2% of calcium hydroxide, and 5% of glass fiber, and mix them evenly for later use;

[0038] b) fabric mixing: according to the percentage by mass, take 53% of diatomite filter aid, 45% of white cement, and 2% of calcium hydroxide, and mix them evenly for later use;

[0039] c) Billet granulation: send the mixed billet into the granulator, and add 0.5% calcium formate and 0.2% ceramic reinforcing agent according to the percentage of the mass of the billet, spray water, stir, extrude, crush, and sieve, Control the moisture content of the powder at 40%, and the particle size between 8-16 mesh;

[0040] d) Fabric granulation: Send the mixed fabric into the granulator, and at th...

Embodiment 3

[0046] A kind of preparation method of multi-functional fire-free breathing brick, this method is to realize through following specific steps and technological conditions:

[0047] a) Billet mixing: According to the percentage by mass, take 47% of diatomite raw soil, 40% of white cement, 3% of silica fume, 8% of calcium hydroxide, and 2% of glass fiber, and mix them evenly for later use;

[0048] b) fabric mixing: according to the percentage by mass, take 52% of diatomite filter aid, 40% of white cement, and 8% of calcium hydroxide, and mix them evenly for later use;

[0049] c) Billet granulation: send the mixed billet into the granulator, and add 0.4% calcium formate and 0.4% ceramic reinforcing agent according to the percentage of the mass of the billet, spray water, stir, extrude, crush, and sieve, Control the moisture content of the powder at 50%, and control the particle size between 8-16 mesh;

[0050] d) Fabric granulation: Send the mixed fabric into the granulator, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com