Method for preparing 2,5-furandicarboxylic acid through electrocatalytic oxidation by using nickel-vanadium phosphide catalyst

A technology of electrocatalytic oxidation and furandicarboxylic acid, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex production process, high catalyst cost, and high reaction efficiency, and achieve raw material conversion High efficiency, high product yield, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

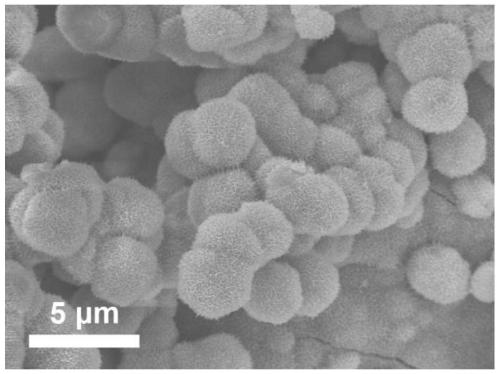

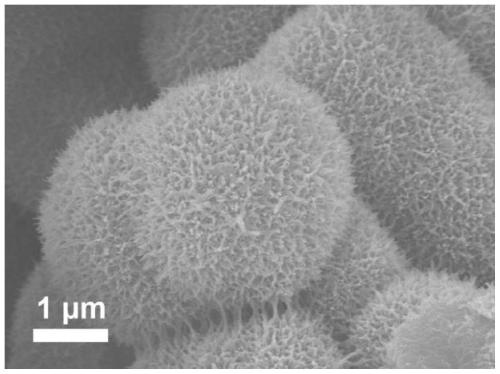

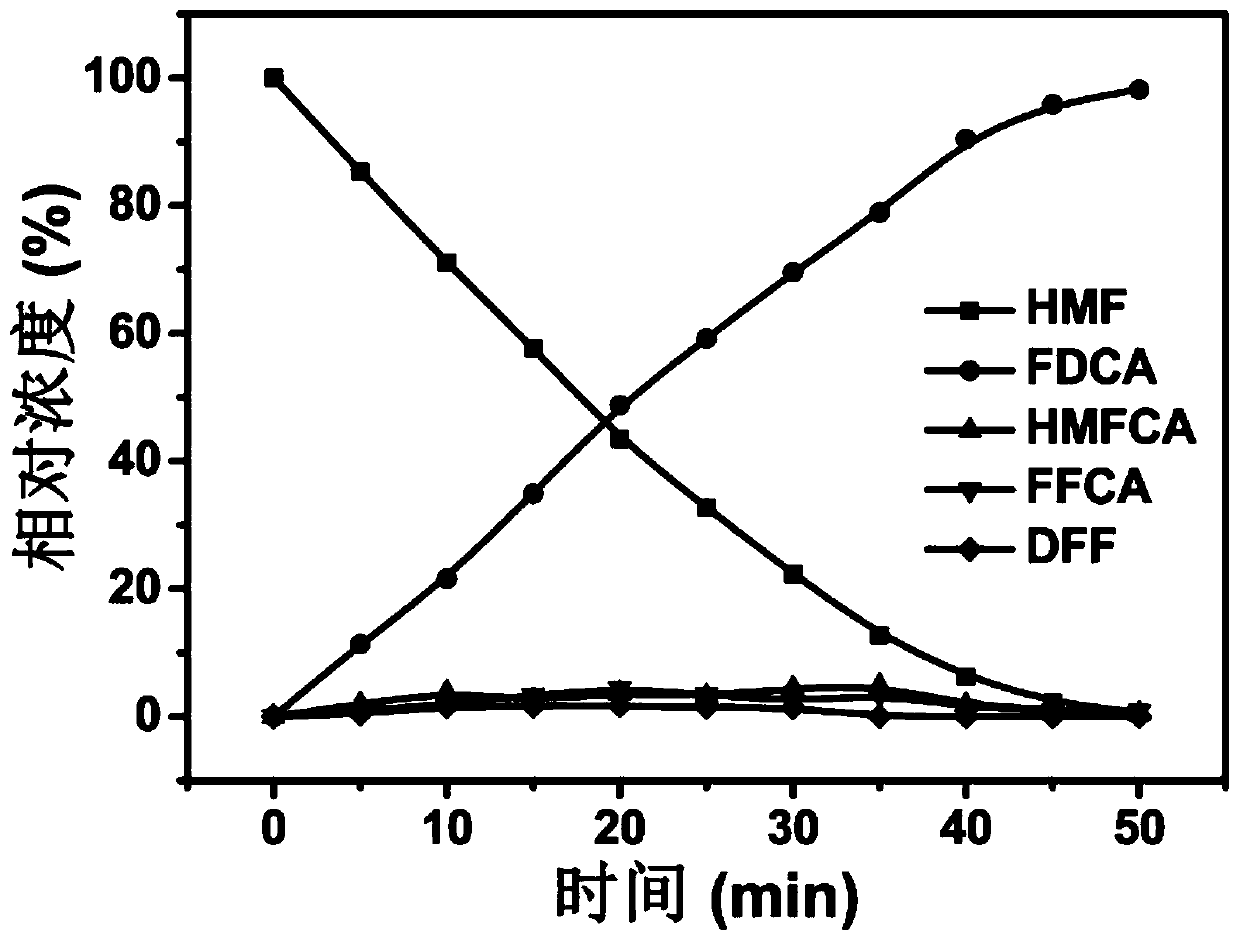

[0034] Example 1: Synthesis of NiVP / NF catalyst and its electrocatalytic oxidation of HMF to prepare FDCA

[0035] (1) According to the feeding ratio, 291 mg of nickel nitrate and 117 mg of ammonium metavanadate were dissolved in 40 mL of water, and ultrasonically dispersed at room temperature for 30 minutes, called A solution;

[0036] (2) Combine the solution A in step (1) and the nickel foam carrier (the size is about 2 × 4 cm 2 ) into a hydrothermal kettle, after hydrothermal reaction at 120°C for 12 hours, cool to room temperature, take out nickel foam, wash twice with distilled water and ethanol alternately, and vacuum dry at 60°C to obtain a supported catalyst;

[0037] (3) Place the dried supported catalyst in step (2) in a tube furnace, place 500 mg of sodium phosphate upstream of the catalyst, and bake at 400°C for 2 hours in an atmosphere of nitrogen gas, then cool to room temperature, the nickel vanadium phosphide catalyst is obtained, marked as NiVP / NF, and its S...

Embodiment 2

[0043] Example 2: Synthesis of NiV / NF catalyst and its electrocatalytic oxidation of HMF to prepare FDCA

[0044] (1) According to the feeding ratio, 291 mg of nickel nitrate and 117 mg of ammonium metavanadate were dissolved in 40 mL of water, and ultrasonically dispersed at room temperature for 30 minutes, called A solution;

[0045] (2) Combine the solution A in step (1) and the nickel foam carrier (the size is about 2 × 4 cm 2 ) into a hydrothermal kettle, reacted hydrothermally at 140°C for 10 hours, cooled to room temperature, took out the nickel foam, washed it twice with distilled water and ethanol alternately, and dried it in vacuum at 60°C to obtain the nickel vanadium compound Catalyst, labeled NiV / NF.

[0046] The catalytic performance of the NiV / NF catalyst prepared in embodiment 2 is tested, and the specific method is as follows:

[0047] Cut the NiV / NF catalyst to about 2 × 2 cm 2 size, directly as the working electrode. The current is controlled by a galvan...

Embodiment 3

[0051] Example 3: Synthesis of NiP / NF catalyst and its electrocatalytic oxidation of HMF to prepare FDCA

[0052] (1) Dissolve 582 mg nickel nitrate in 40 mL water and ultrasonically disperse at room temperature for 30 minutes, called A solution;

[0053] (2) Combine the solution A in step (1) and the nickel foam carrier (the size is about 2 × 4 cm 2 ) into a hydrothermal kettle, reacted hydrothermally at 160°C for 6 hours, cooled to room temperature, took out the nickel foam, washed it twice with distilled water and ethanol alternately, and vacuum-dried at 60°C to obtain a supported catalyst;

[0054] (3) Place the dried supported catalyst in step (2) in a tube furnace, place 500 mg of sodium hypophosphite upstream of the catalyst, and bake it at 300°C for 1.5 hours under an atmosphere of argon. , cooled to room temperature to obtain the nickel phosphide catalyst, marked as NiP / NF.

[0055] The catalytic performance of the NiP / NF catalyst prepared in embodiment 3 is tested,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com