Fibrous filter pipe and preparation method and applications thereof

A technology of fiber filtration and filter tubes, applied in application, filtration circuit, filtration separation, etc., can solve the problems of poor resistance to heavy rainfall, loss of anti-scouring, large coverage area, etc., to reduce the amount of sediment loss and prevent rainwater runoff , the effect of preventing soil loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 A fiber filter tube

[0032] A fiber filter tube, which is wound to form a hollow tubular structure by wrapping an engineering composite material with a braided net;

[0033] The weight of the fiber filter tube is 0.7 kg / m; the thickness of the tube is 13 cm; the inner diameter of the tube is 15 cm.

[0034] The material of the woven mesh is polypropylene, the mesh aperture is 1*1cm, and the mesh diameter is 0.5mm.

[0035] Engineering composite materials, the raw material components include wood fiber, modified artificial fiber and flocculant; the amount of flocculant is 1 / 5 of the composite engineering material; the flocculant is a commercially available composite flocculant.

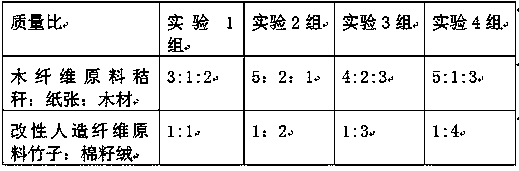

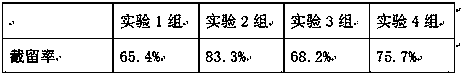

[0036] The wood fiber: raw materials are straw, paper, wood, the mass ratio is 5:2:1; the length of the wood fiber is 1cm, and the diameter is 0.5mm;

[0037] The modified artificial fiber: raw materials are bamboo and cotton linters, the mass ratio is 1:2; the modified artificial f...

Embodiment 2

[0050] Example 2 A process for preparing a fiber filter tube

[0051] Specific steps are as follows:

[0052] (1) Preparation of wood fiber

[0053] Mix the straw, paper and wood, place them in hot water at 180°C, and after 30 minutes, draw them to form wood fibers, and cut them with a rotary hob-type fiber chopping machine to form wood fibers with a length of 1 cm and a diameter of 0.5 mm;

[0054] (2) Preparation of modified man-made fibers

[0055]Bamboo and cotton linters are reacted with sodium hydroxide solution, the reaction temperature is 40°C, and the reaction time is 40 minutes; after the reaction, the reaction solution is placed in an environment fully filled with carbon disulfide, and the amount of carbon disulfide intake is the weight of the reaction solution 35% of 35%; the reaction solution reacts with carbon disulfide at an initial temperature of 20°C and an end temperature of 32°C for 130 minutes to obtain the final reaction solution and make modified artifi...

Embodiment 3

[0063] Example 3 Application of a fiber filter tube in slope greening

[0064] The specific method is as follows:

[0065] (1) Level the slope and remove obstacles with a diameter greater than 3cm;

[0066] (2) After determining the installation position of the fiber filter tube, excavate a fixed groove with a depth of 7cm and a width of 15cm on the slope, place the fiber filter tube in it, and place loose planting soil upstream of the tube; (The installation environment of the fiber filter tube is On the slope surface, the side near the top of the slope is upstream, and the side near the bottom of the slope is downstream; the effect of placing planting soil is to bury the gap between the fixing groove and the fiber filter pipe, so that there is no obvious fault trace on the slope.)

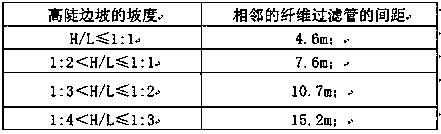

[0067] The fiber filter tubes are placed on the surface of the slope body in an arc shape, and are distributed on the slope surface at a certain horizontal interval, as shown in the following ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com