High-toughness heat-resistant Mg-Y alloy suitable for gravity casting and preparation method thereof

A gravity casting and alloying technology, which is applied in the field of high-strength, toughness and heat-resistant Mg-Y alloys and their preparation, can solve the problems of inability to achieve the performance of cast aluminum alloys, insufficient heat resistance, etc., and achieve overcoming thermal cracking tendency, small solidification interval, Effect of High Temperature Creep Properties Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

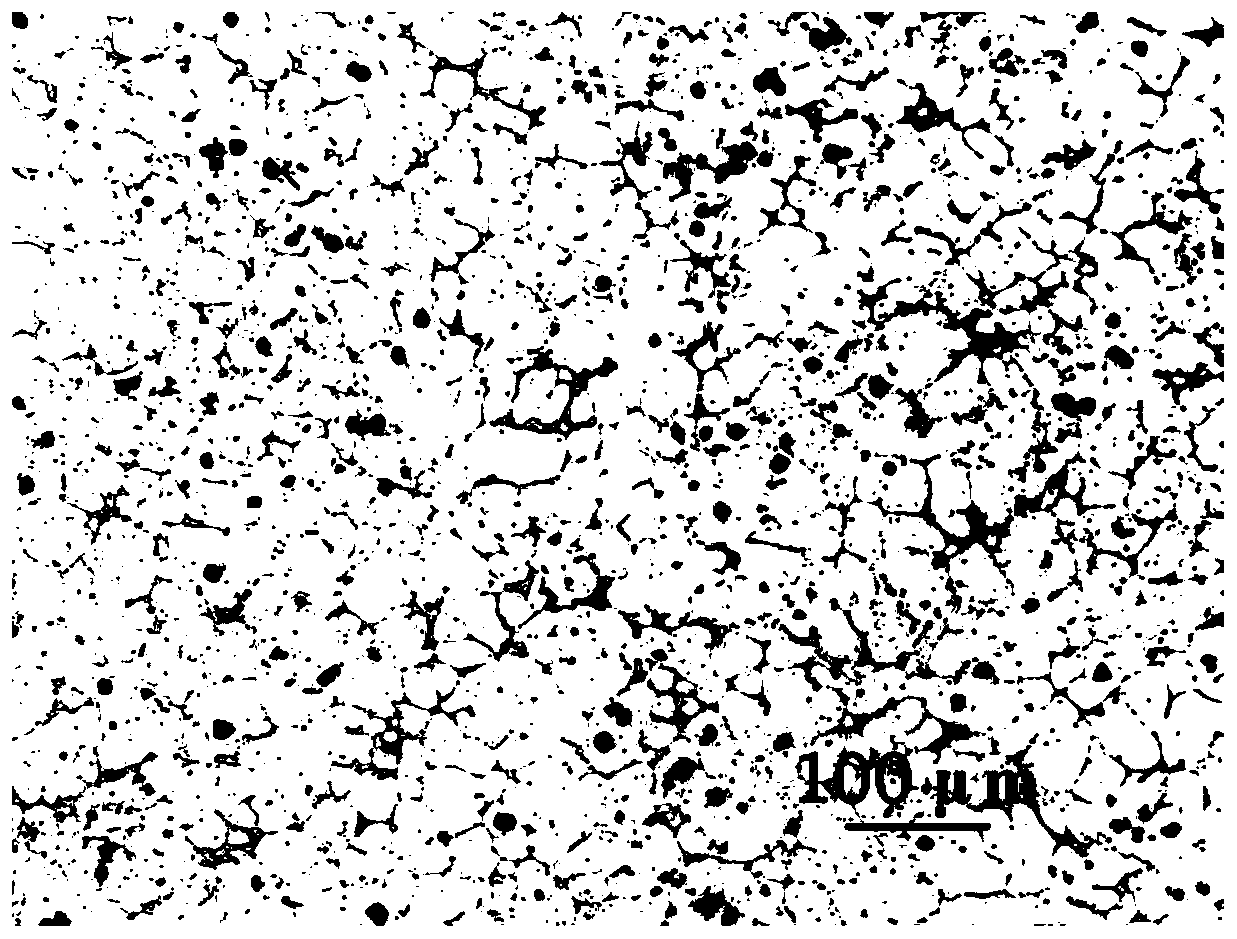

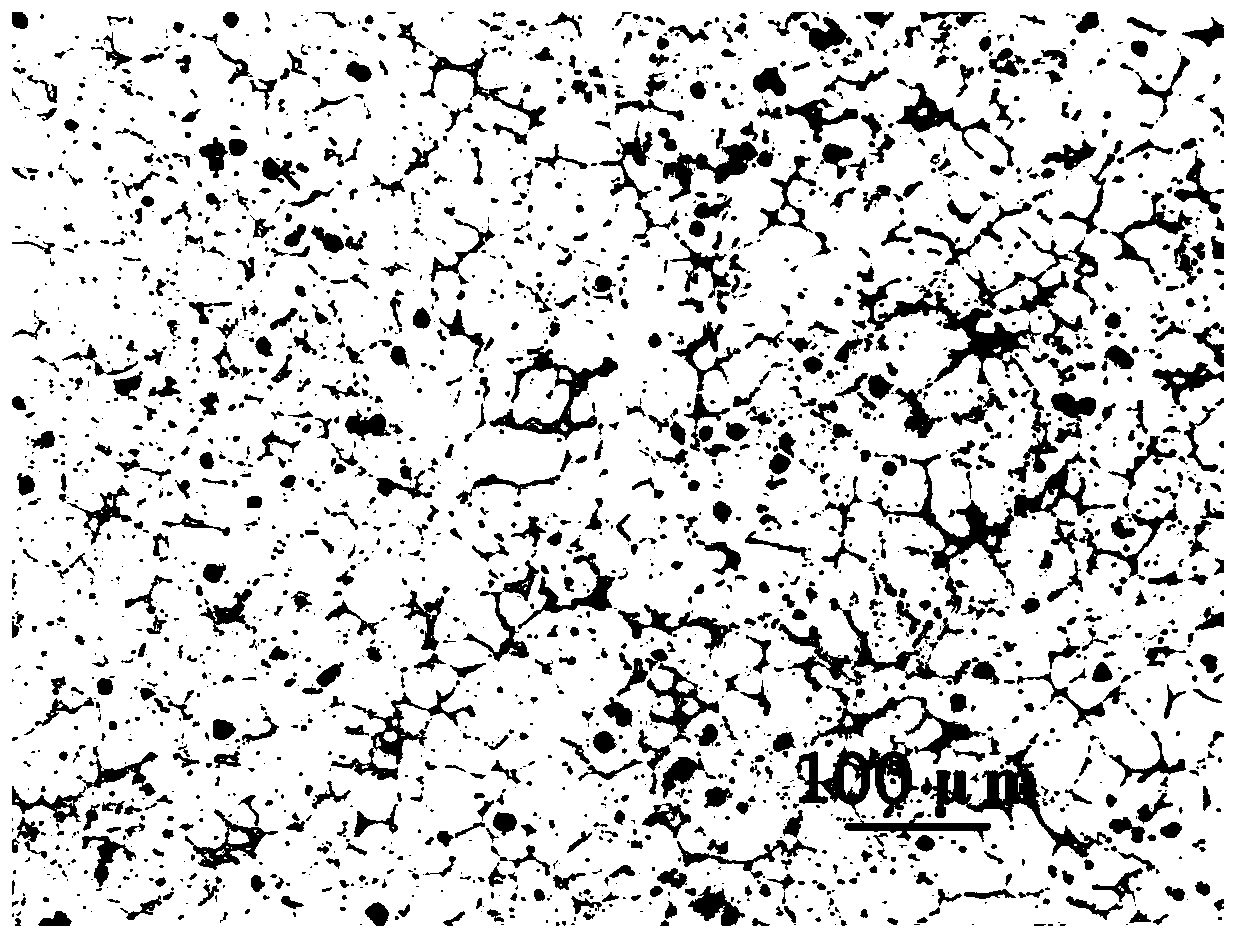

Image

Examples

Embodiment 1

[0039] The percentage by weight of a high-strength, tough, heat-resistant Mg-Y alloy suitable for gravity casting related to this embodiment is: according to the theoretical ratio, 4.0% Y, 3.0% Zn, 0.5% Al, 0.3% Mn, 0.01% Ti, 0.01% B, the balance is Mg and other unavoidable impurities.

[0040] Its preparation method is: (1) according to the above-mentioned Mg-Y alloy composition and stoichiometric ratio, calculate the consumption of required raw materials; mix industrial pure magnesium ingot, industrial pure zinc, industrial pure aluminum ingot and Mg-Y and Mg-Mn intermediate Remove the oxide layer from the alloy, dry and preheat to 200°C; calculate the amount of raw materials required according to the composition and stoichiometric ratio of the alloy; (2) melt the industrial pure magnesium ingot accounting for 25% of the crucible height at 680°C into After the molten pool, the protective gas argon is introduced, and the remaining magnesium ingots are added; (3) after the mag...

Embodiment 2

[0043] The percentage by weight of a high-strength, tough, heat-resistant Mg-Y alloy suitable for gravity casting related to this embodiment is: according to the theoretical ratio, 8.0% Y, 3.2% Zn, 0.8% Al, 0.1% Mn, 0.08% Ti, The balance is Mg and other unavoidable impurities.

[0044] Its preparation method is: (1) according to above-mentioned Mg-Y alloy composition and stoichiometric ratio, calculate the consumption of required raw material; Deoxidize industrial pure magnesium ingot, industrial pure zinc, industrial pure aluminum ingot and MgY30 and MgMn10 master alloy layer and dry and preheat to 180°C; calculate the amount of raw materials required according to the composition and stoichiometric ratio of the alloy; (2) After melting the industrial pure magnesium ingot accounting for 20% of the crucible height into a molten pool at 685°C, Introduce a protective gas containing 0.2% volume fraction of SF 6 and CO 2 (3) After the magnesium ingots are completely melted, heat ...

Embodiment 3

[0047] The percentage by weight of a high-strength and tough heat-resistant Mg-Y alloy suitable for gravity casting related to this embodiment is: according to the theoretical ratio, 4.0% Y, 4.0% Zn, 0.9% Al, 0.2% Mn, 0.05% Ti, 0.03% B, the balance is Mg and other unavoidable impurities.

[0048] Its preparation method is (1): according to the above-mentioned Mg-Y alloy composition and stoichiometric ratio, calculate the consumption of required raw material; Deoxidize industrial pure magnesium ingot, industrial pure zinc, industrial pure aluminum ingot and MgY30 and MgMn10 master alloy layer and dry and preheat to 180°C; calculate the amount of raw materials required according to the composition and stoichiometric ratio of the alloy; (2) after melting the industrial pure magnesium ingot accounting for 22% of the crucible height into a molten pool at 675°C, Pass through the protective gas argon, and add the remaining magnesium ingots; (3) After the magnesium ingots are complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com