LED epitaxial growth method suitable for 4-inch substrate

An epitaxial growth and substrate technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven growth of materials in the chip, low product yield, low luminous efficiency, and large warping of epitaxial wafers, etc., to improve luminous efficiency And antistatic ability, antistatic and other performance improvement, improve the effect of crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

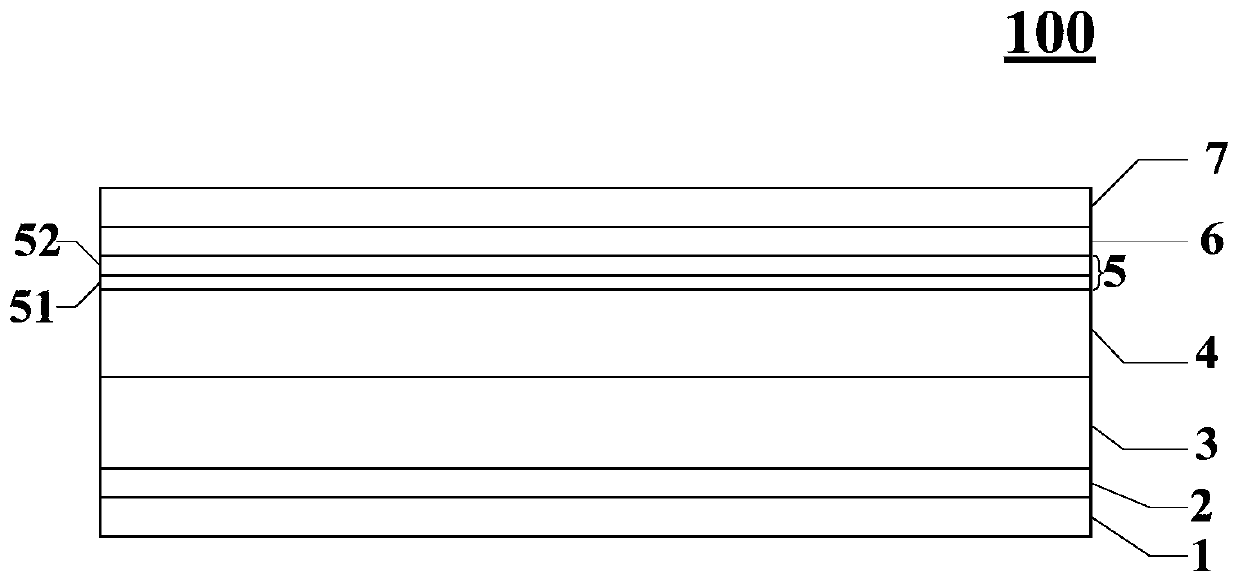

[0057] figure 1 Shown is a schematic structural diagram of an LED epitaxial layer 100 in the prior art. The LED epitaxial layer 100 in the prior art includes: a substrate 1, a low-temperature buffer layer 2, an undoped GaN layer 3, and Si-doped n-type GaN Layer 4, active layer MOW 5, P-type AlGaN layer 6, magnesium-doped P-type GaN layer 7; wherein, the active layer MOW 5 includes In y1 Ga (1-y1) N layer 51 and GaN layer 52 .

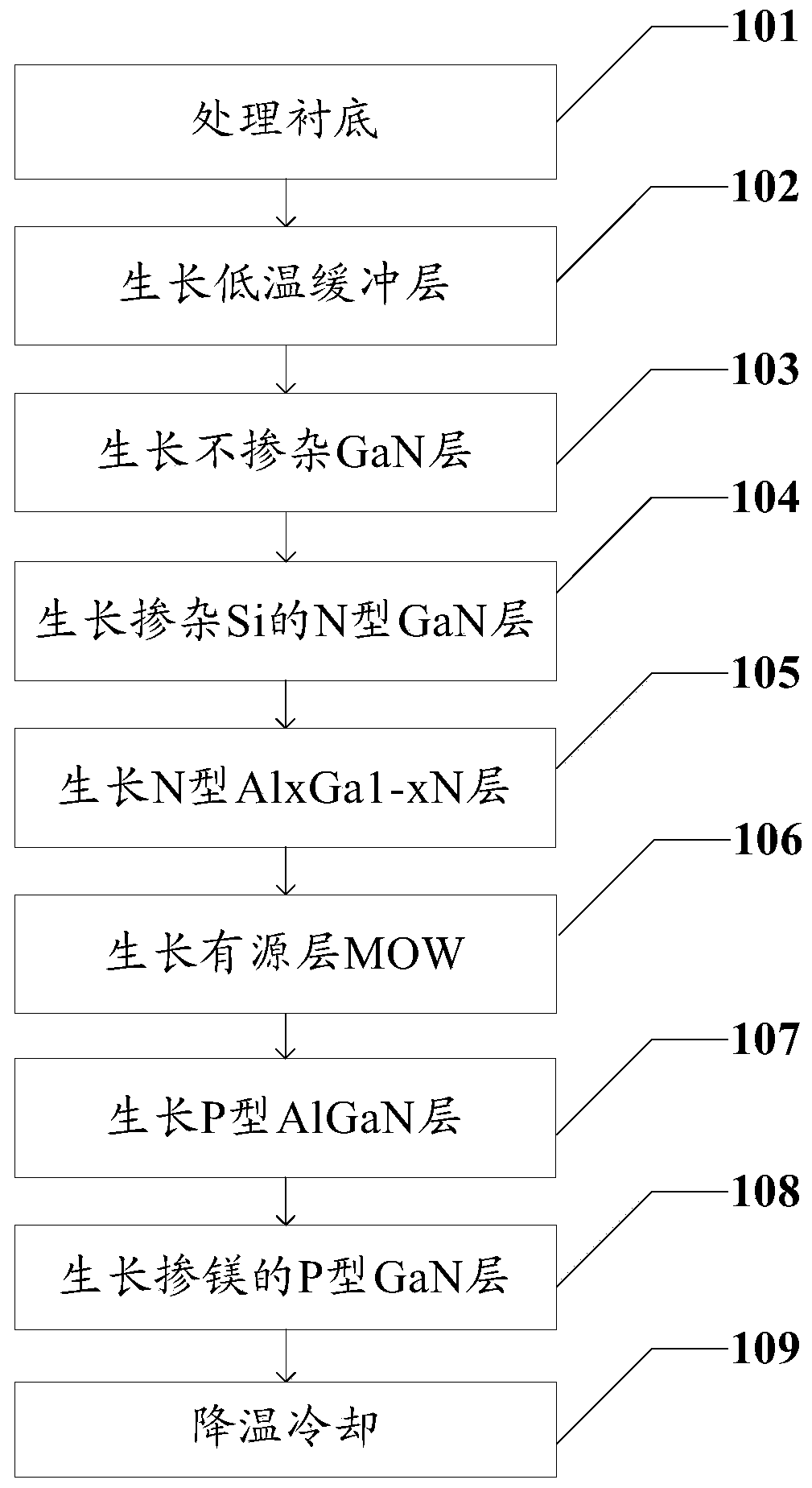

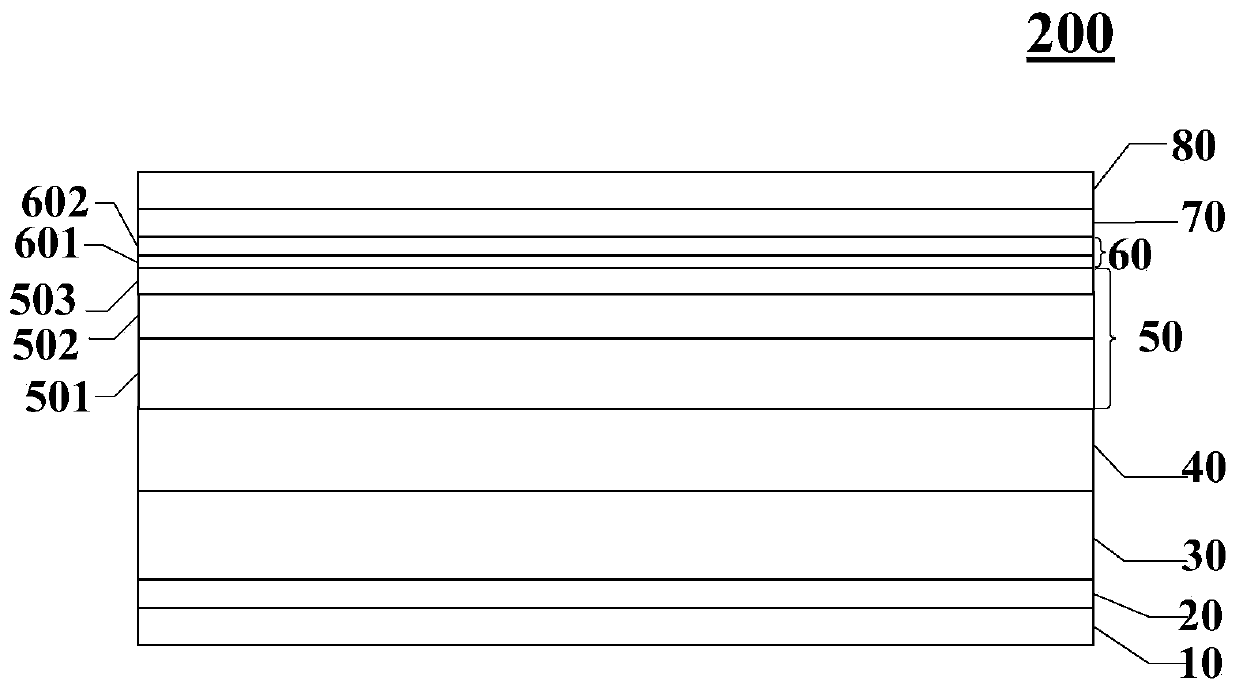

[0058] figure 2 Shown is a flow chart of an LED epitaxial growth method suitable for a 4-inch substrate provided by the embodiment of the present application, image 3 Shown is a schematic structural diagram of the LED epitaxial layer 200 in the embodiment of the present application, please refer to figure 2 and image 3 , the embodiment of the present application provides an LED epitaxial growth method suitable for a 4-inch substrate, including:

[0059] Step 101, processing the substrate 10;

[0060] Step 102, growing a low-temperature buffer...

Embodiment 2

[0098] Please combine figure 1 , the LED epitaxial layer growth method in the prior art includes: processing the substrate 1, growing a low-temperature buffer layer 2, growing an undoped GaN layer 3, growing an n-type GaN layer 4 doped with Si, growing an active layer MOW 5, growing P-type AlGaN layer 6, growth of magnesium-doped P-type GaN layer 7, epitaxial layer structure, please refer to figure 1 . The embodiment of the present application adds N-type Al on the basis of the prior art x Ga 1-x N layer 50. In this embodiment, 1000 pieces of sample 1 are prepared according to the LED epitaxial growth method in the prior art, and 1000 pieces of sample 2 are prepared according to the LED epitaxial growth method of the present application. After the samples were grown, 4 samples each of sample 1 and sample 2 were randomly selected, and the XRD102 surface of the epitaxial wafer was tested under the same conditions. Please refer to Table 1. Table 1 shows the epitaxial XRD test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com