Titanium dioxide colloidal modified diaphragm for lithium-sulfur battery, preparation method thereof, and lithium-sulfur battery

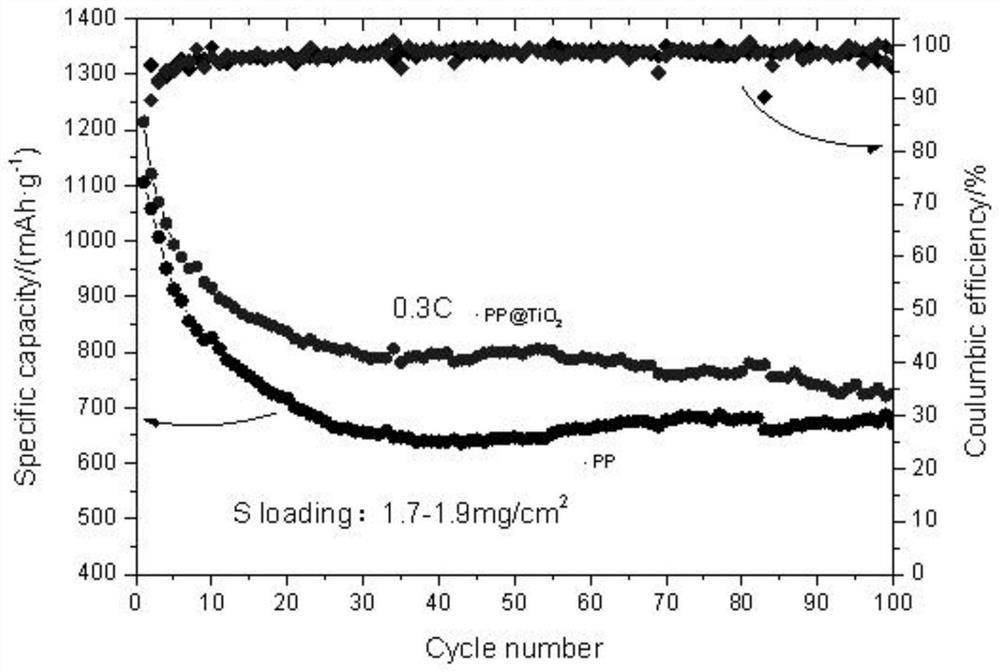

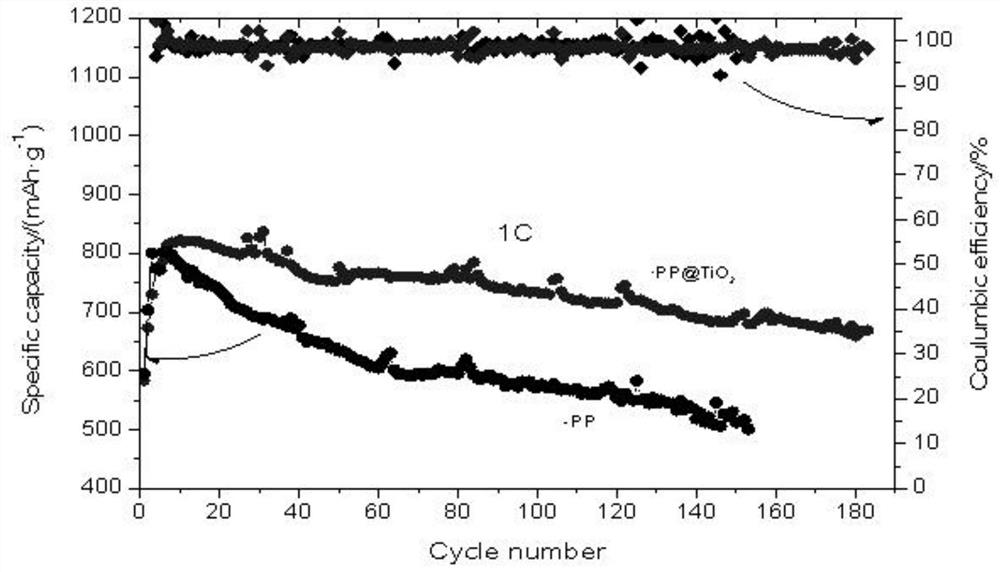

A technology for titanium dioxide and lithium-sulfur batteries, which is applied in the field of titanium dioxide colloid-modified diaphragms for lithium-sulfur batteries and its preparation, can solve problems such as poor electrical conductivity, damage to the surface of lithium metal, and reduce Coulombic efficiency, etc., and achieve uniform and dense coating layers and improved Cycling stability, effect of reducing Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the preparation method of titanium dioxide colloidal modified membrane

[0032] Include the following steps:

[0033](1) Preparation of titanium dioxide colloid: add 250mL of ethanol and a stirrer to a 500mL beaker, then add 1.5mL of 25wt% concentrated ammonia water (the volume ratio of concentrated ammonia water to ethanol is 1:167), stir for 30 minutes to make the pH of the solution uniform, add 1.5 mL of tetrabutyl titanate (volume ratio of tetrabutyl titanate to ethanol is 1:167) was stirred in a water bath at 45°C for 6 hours to obtain titanium dioxide colloid with Tyndall effect;

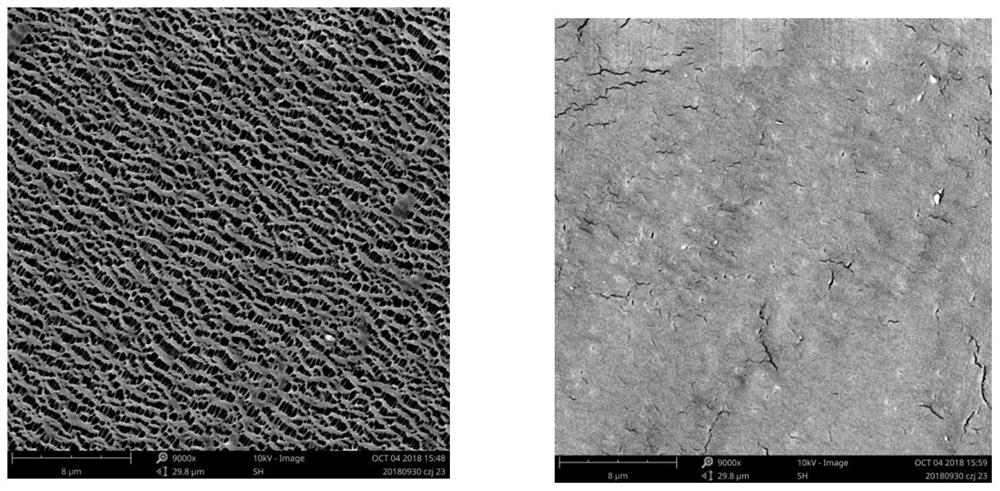

[0034] (2) Titanium dioxide colloid-coated PP diaphragm: Use the dipping-lifting method to quickly put the PP diaphragm into the TiO2 sol. After the PP diaphragm is completely immersed in the sol, quickly time it for 15 seconds, with a value of about 3 cm s -1 Pull out at a constant speed, dry naturally for 15 minutes, then transfer to a drying oven at 55°C for 40 minutes...

Embodiment 2

[0041] Embodiment 2: the preparation method of titanium dioxide colloidal modified membrane

[0042] (1) Preparation of titanium dioxide colloid: Add 250mL of ethanol and a stirrer into a 500mL beaker, then add 0.9mL of 25wt% concentrated ammonia water (the volume ratio of concentrated ammonia water to ethanol is 1:278), stir for 30 minutes to make the pH of the solution uniform, add After 1.0 mL of tetrabutyl titanate (the volume ratio of tetrabutyl titanate to ethanol is 1:250), stir in a water bath at 45°C for 4 hours to obtain titanium dioxide colloid with Tyndall effect;

[0043] (2) Titanium dioxide colloid-coated PP diaphragm: Use the dipping-lifting method to quickly put the PP diaphragm into the TiO2 sol. After the PP diaphragm is completely immersed in the sol, quickly count for 30 seconds, with a value of about 3 cm s -1 Pull out at a constant speed, dry naturally for 15 minutes, then transfer to a drying oven at 55°C for 40 minutes;

[0044] (3) Multiple coatings:...

Embodiment 3

[0046] With reference to Example 2, the difference is that the number of repetitions in step (3) is 2 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com