3D printing one-time molding water-based zinc-ion battery and its realization method

A zinc-ion battery, 3D printing technology, applied in secondary batteries, battery electrodes, battery pack components and other directions, can solve the problems of high process cost, complex procedures, strict environmental requirements, etc., to achieve simple process, wide application prospects, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

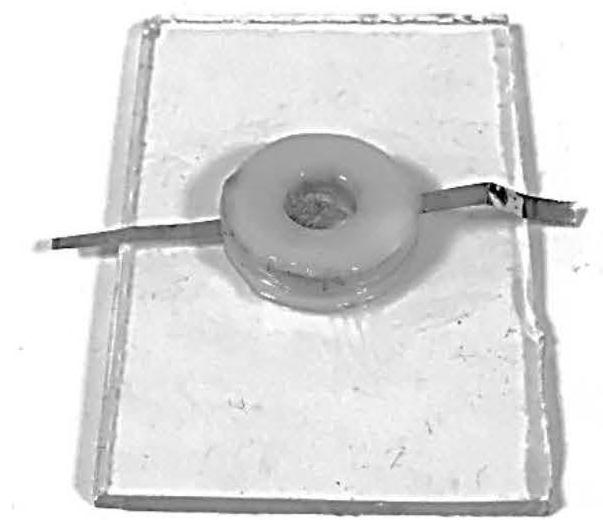

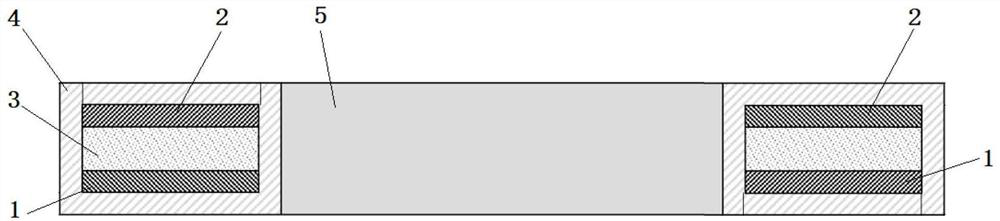

Image

Examples

Embodiment 1

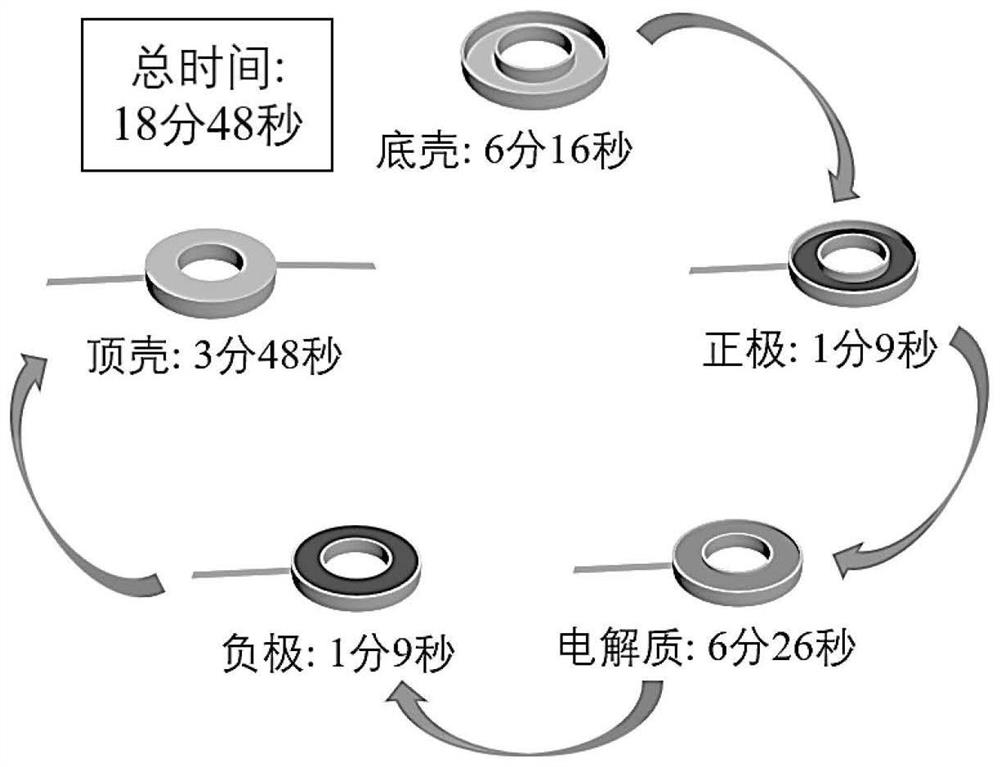

[0022] Such as image 3 As shown, this embodiment includes the following steps:

[0023] Step 1. Weigh 400 mg manganese dioxide, 80 mg nanocellulose, 20 mg graphene oxide, 200 mg acetylene black, 2.3 g zinc sulfate heptahydrate, 67.61 mg manganese sulfate monohydrate and mix with 4 mL deionized water to obtain a positive electrode Material;

[0024] Step 2. Weigh 600 mg zinc powder, 80 mg nanocellulose, 30 mg graphene oxide, 200 mg acetylene black, 2.3 g zinc sulfate heptahydrate, 67.61 mg manganese sulfate monohydrate and mix with 4 mL deionized water to obtain the negative electrode material ;

[0025] Step 3. Weigh 1200 mg polyvinylidene fluoride, 60 mg Pluronic, 80 mg nanocellulose, 30 mg graphene oxide, 2.3 g zinc sulfate heptahydrate, 67.61 mg manganese sulfate monohydrate and mix with 4 mL deionized water to obtain electrolyte Material;

[0026] Step 4. Weigh 1.5 g of nano-alumina and mix with 4 mL of photosensitive resin to obtain the battery case material.

[002...

Embodiment 2

[0031] Such as image 3 As shown, this embodiment includes the following steps:

[0032] Step 1. Weigh 400 mg of vanum pentoxide, 80 mg of nanocellulose, 20 mg of graphene oxide, 200 mg of acetylene black, 2.3 g of zinc sulfate heptahydrate, 67.61 mg of manganese sulfate monohydrate and mix them with 4 mL of deionized water to obtain Cathode material;

[0033] Step 2. Weigh 600 mg zinc powder, 80 mg nanocellulose, 30 mg graphene oxide, 200 mg acetylene black, 2.3 g zinc sulfate heptahydrate, 67.61 mg manganese sulfate monohydrate and mix with 4 mL deionized water to obtain the negative electrode material ;

[0034] Step 3. Weigh 1200 mg polyvinylidene fluoride, 60 mg Pluronic, 80 mg nanocellulose, 30 mg graphene oxide, 2.3 g zinc sulfate heptahydrate, 67.61 mg manganese sulfate monohydrate and mix with 4 mL deionized water to obtain electrolyte Material;

[0035] Step 4. Weigh 1.5 g of nano-alumina and mix with 4 mL of photosensitive resin to obtain the battery case materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com