An organic polymer sulfur/nanocarbon-based composite material and its application in lithium-sulfur batteries

A composite material, lithium-sulfur battery technology, applied in nanotechnology, battery electrodes, nanotechnology, etc., can solve the problems of capacity fading, slow dissolution, reduced Coulomb efficiency, etc., to achieve improved conductivity, mild reaction, and improved overall performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

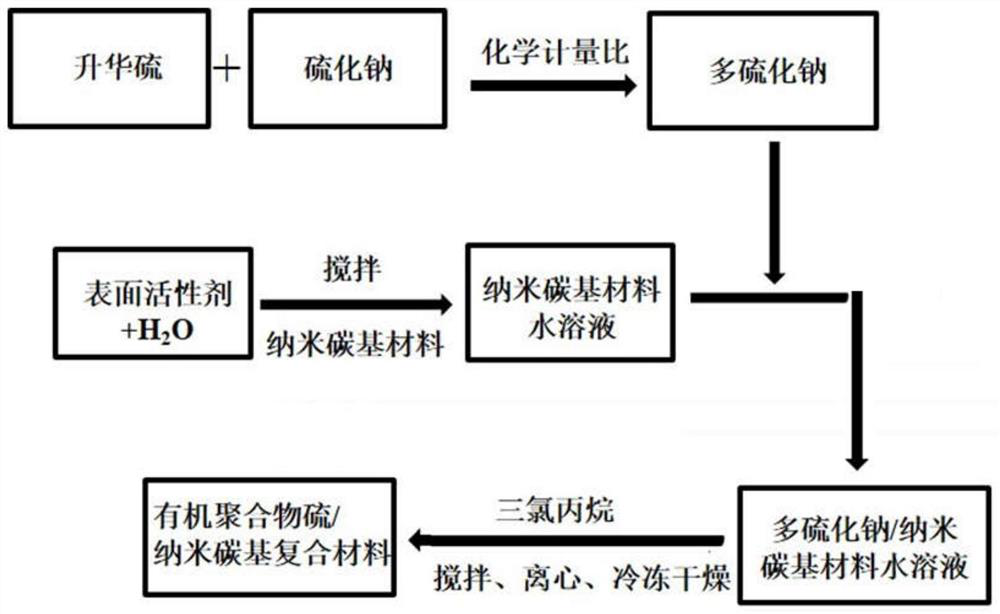

[0029] The preparation process of the organic polymer sulfur / nano-carbon-based composite material in this embodiment is as follows figure 1 , the specific preparation process is: weigh 6.4g sublimated sulfur and 24g sodium sulfide nonahydrate (Na 2 S·9H 2 O) into 100ml of deionized water, under the protection of inert gas, stir until clarified to obtain an aqueous sodium trisulfide solution with a concentration of 1mol / L. Weigh 7.3g of cetyltrimethylammonium bromide surfactant and dissolve it in 190mL of deionized water, stir until clear, add 500mg of graphene and stir for 1h, add 10mL of the sodium trisulfide solution prepared above, stir for 0.5h, Then add 2.15mL trichloropropane, stir for 4 hours, and process at a temperature of 30°C to obtain an organic polymer sulfur / graphene composite material solution. The solution is repeatedly washed with deionized water, centrifuged, and freeze-dried to finally obtain an organic polymer sulfur / Graphene composite material, the sulf...

Embodiment 2

[0032] The difference between embodiment 2 and embodiment 1 is that the kinds of sodium polysulfide and surfactant are different. Weigh 9.6 g of sublimed sulfur and 24 g of sodium sulfide nonahydrate into 100 ml of deionized water, and stir until clarified under the protection of an inert gas to obtain an aqueous sodium tetrasulfide solution with a concentration of 1 mol / L. Weigh 7.3g of sodium lauryl sulfate surfactant and dissolve it in 190mL of deionized water, stir until clear, add 600mg of graphene and stir for 1h, add 10mL of sodium trisulfide prepared above, stir for 0.5h, then add 2.15mL of trisulfide Chloropropane, stirring time 4h, processing temperature 30 ℃, obtain organic polymer sulfur / graphene composite material solution, this solution is repeatedly washed with deionized water, centrifuged, freeze-dried, finally obtain organic polymer sulfur / graphene composite material , the sulfur content in the prepared organic polymer sulfur / graphene composite material is 65w...

Embodiment 3

[0034] The difference between embodiment 3 and embodiment 1 is that the kinds of sodium polysulfide and surfactant are different. Weigh 12.8 g of sublimed sulfur and 24 g of sodium sulfide nonahydrate into 100 ml of deionized water, and stir until clarified under the protection of an inert gas to obtain an aqueous solution of sodium pentasulfide with a concentration of 1 mol / L. Weigh 7.3g of polyethylene glycol octylphenyl ether surfactant and dissolve it in 190mL of deionized water, stir until clear, add 500mg of graphene and stir for 1h, add 10mL of sodium trisulfide prepared above, stir for 0.5h, then add 2.15 mL of trichloropropane, stirred for 4 hours, and treated at a temperature of 30 °C to obtain an organic polymer sulfur / graphene composite material solution. The solution was repeatedly washed with deionized water, centrifuged, and freeze-dried to finally obtain an organic polymer sulfur / graphene composite material solution. Wall carbon nanotube composite material, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com