Ultrasonic preparation method of gold/porous palladium core-shell structure nanoparticles

A gold nanoparticle, core-shell structure technology is applied in the field of ultrasonic preparation of gold/porous palladium core-shell structure nanoparticles, which can solve the problems of difficult control of nanoparticle size and morphology, long reaction time, high reaction temperature, etc. The effect of strong controllability of morphology and particle size, mild reaction conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 100 mL of 0.01% chloroauric acid aqueous solution and heat to boiling, and then quickly add 3 mL of 1% sodium citrate solution. Keep boiling for 15 minutes, and cool the solution to room temperature to obtain a hydrosol of gold nanoparticles.

[0029] Weigh 0.0177 g of palladium chloride and dissolve it in 2 mL of 50.0 mmol / L hydrochloric acid solution, and then add deionized water to dilute to 100 mL to prepare a 1.0 mmol / L chloropalladic acid solution.

[0030] Mix 0.06g of polyethylene glycol (PEG 4000), 0.25mL of 1.0mmol / L chloropalladic acid solution and 1mL of 100mmol / L ascorbic acid solution in 20mL of deionized water, and then slowly drop 1mL of gold sol Solution. Then, it was reacted for 0.5 hours under 200W ultrasonic conditions, and finally the product was cleaned and separated to obtain gold / porous palladium core-shell structured nanoparticles.

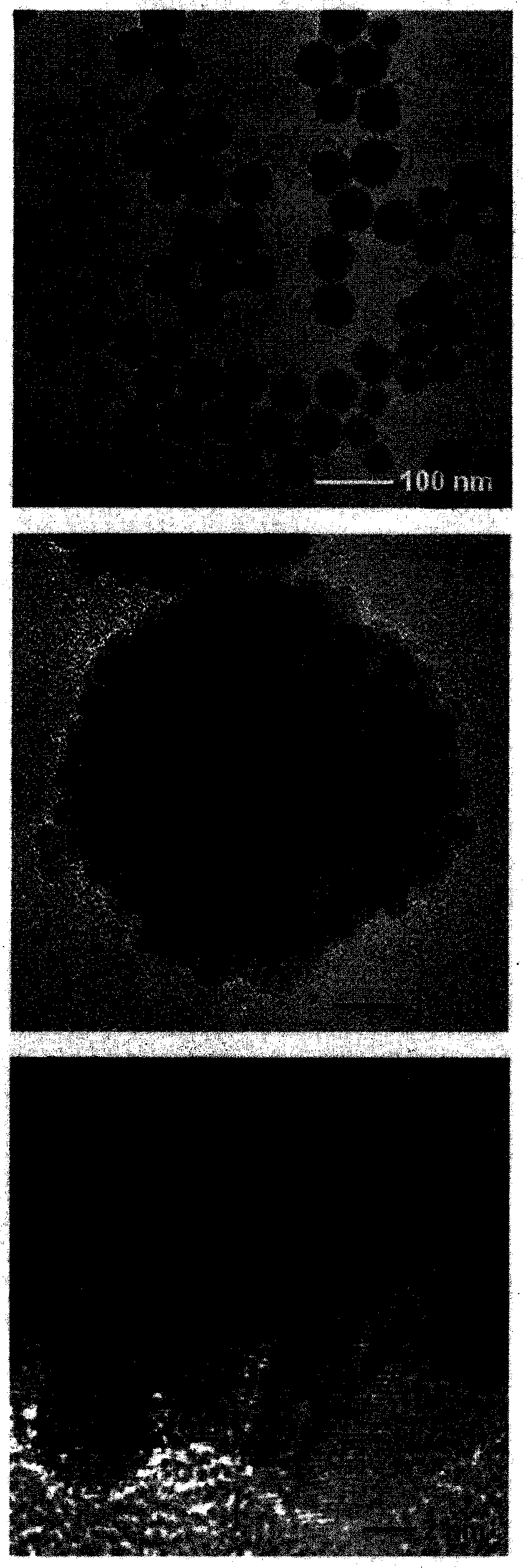

[0031] The product obtained in this example was observed under a transmission electron microscope, and the result...

Embodiment 2

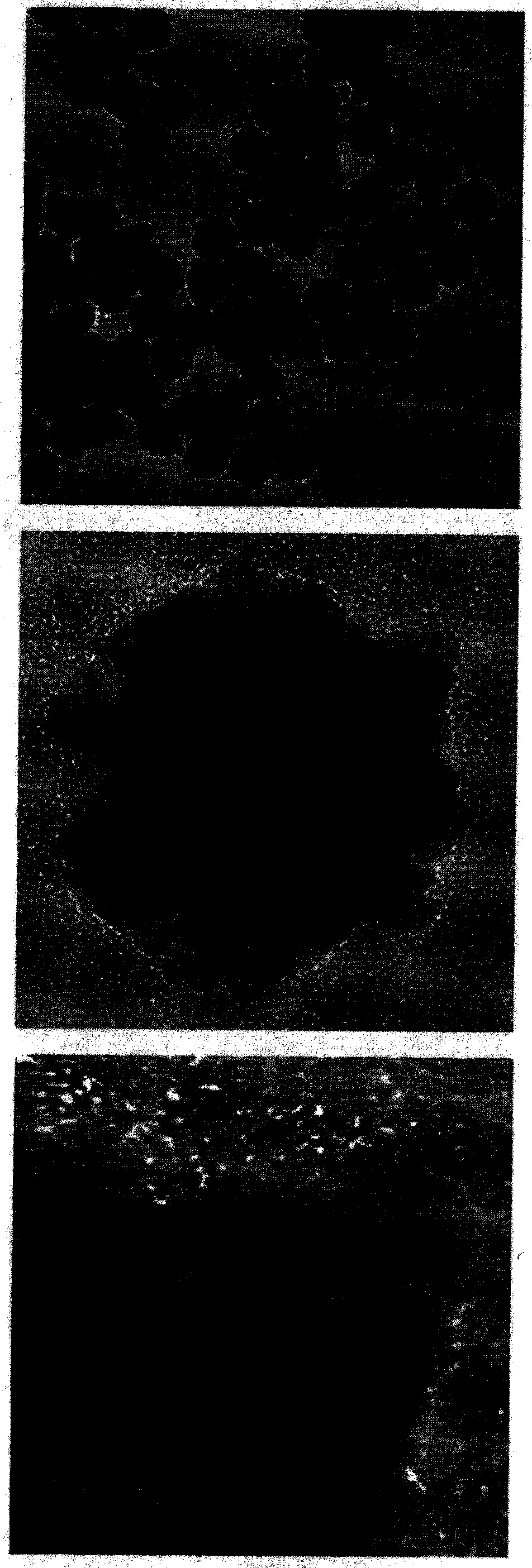

[0033] The process is similar to that of Example 1, but when preparing gold / porous palladium core-shell structure nanoparticles, the ultrasonic power is changed to 800W, and other reaction conditions are kept unchanged. figure 2 This is a transmission electron microscope image of the product obtained in this example. It can be seen from the image that the porous structure of the palladium shell layer is significantly different from that of the product of Example 1.

Embodiment 3

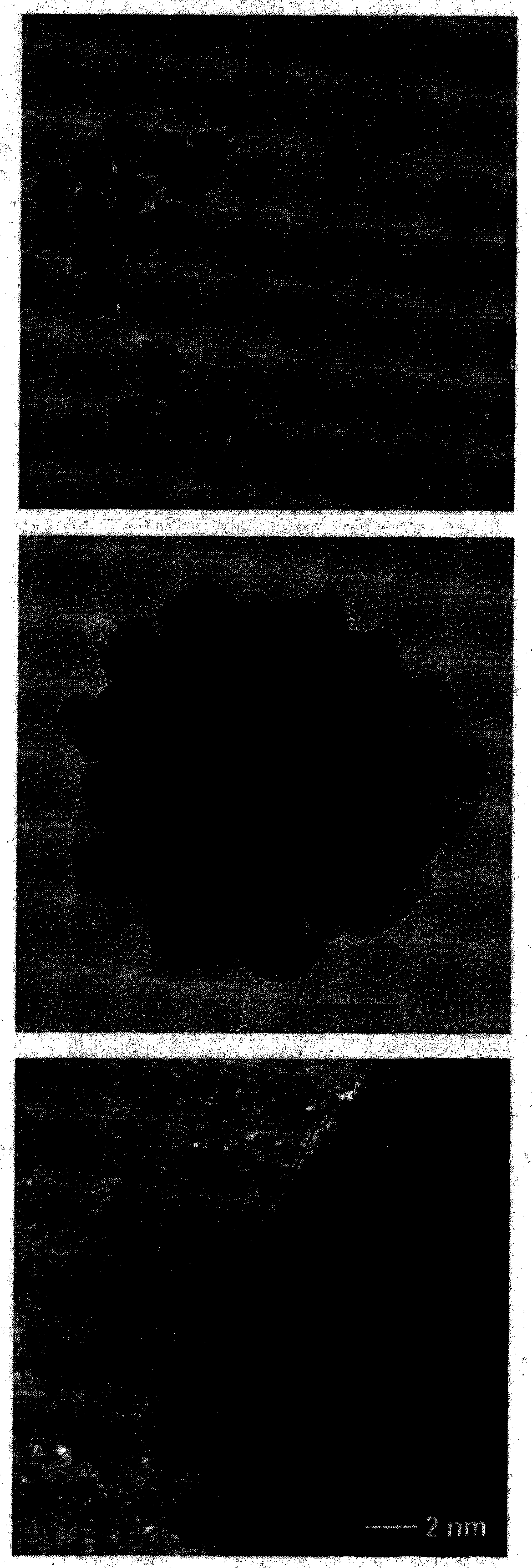

[0035] The process is similar to that of Example 1, but when preparing gold / porous palladium core-shell structure nanoparticles, 0.06g polyethylene glycol (PEG 4000) is changed to 0.36g cetyltrimethylammonium chloride, Keep other reaction conditions unchanged. image 3 This is a transmission electron microscope image of the product obtained in this example. Compared with the structure of the product of Example 1, the shell layer has a larger palladium particle size and a denser porous structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com