High-flux microfluidic body-wave sorting chip and preparation method thereof

A microfluidic, high-throughput technology, applied in the field of micro-total analysis, can solve the problems of low sorting throughput, increase the preparation cost, and unfavorable life safety of experimenters, etc., to achieve improved fluid flux and large-throughput sorting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

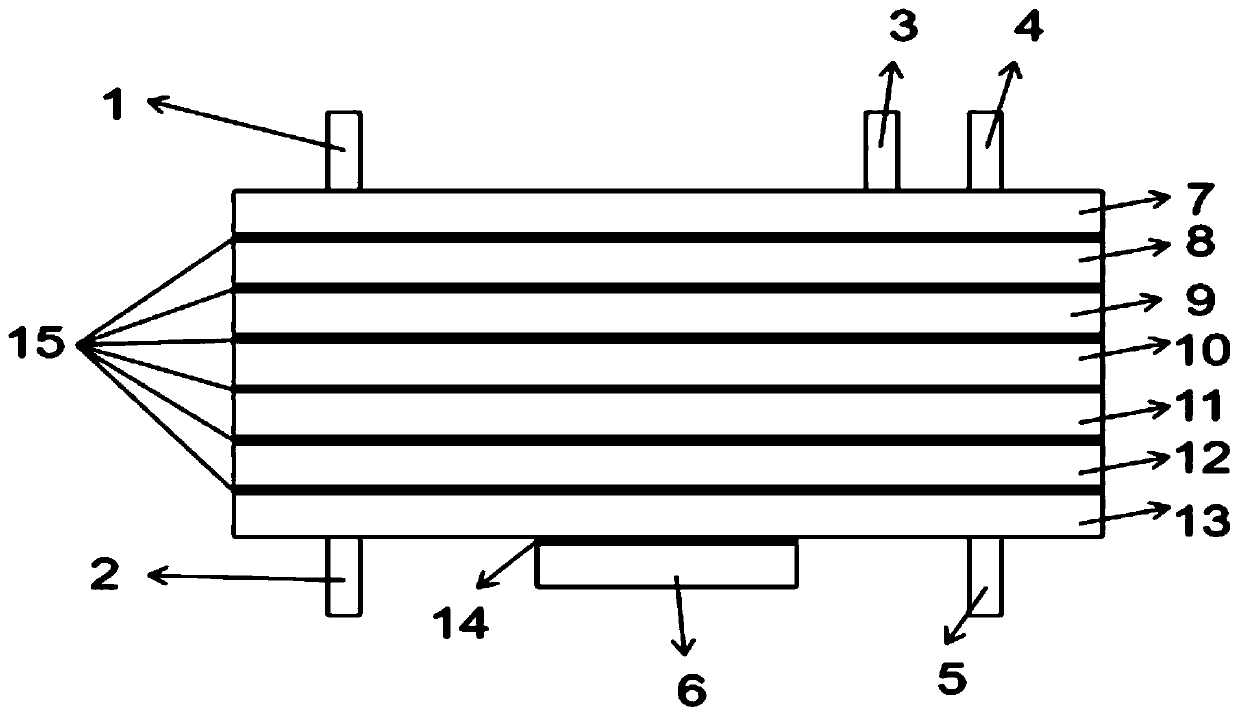

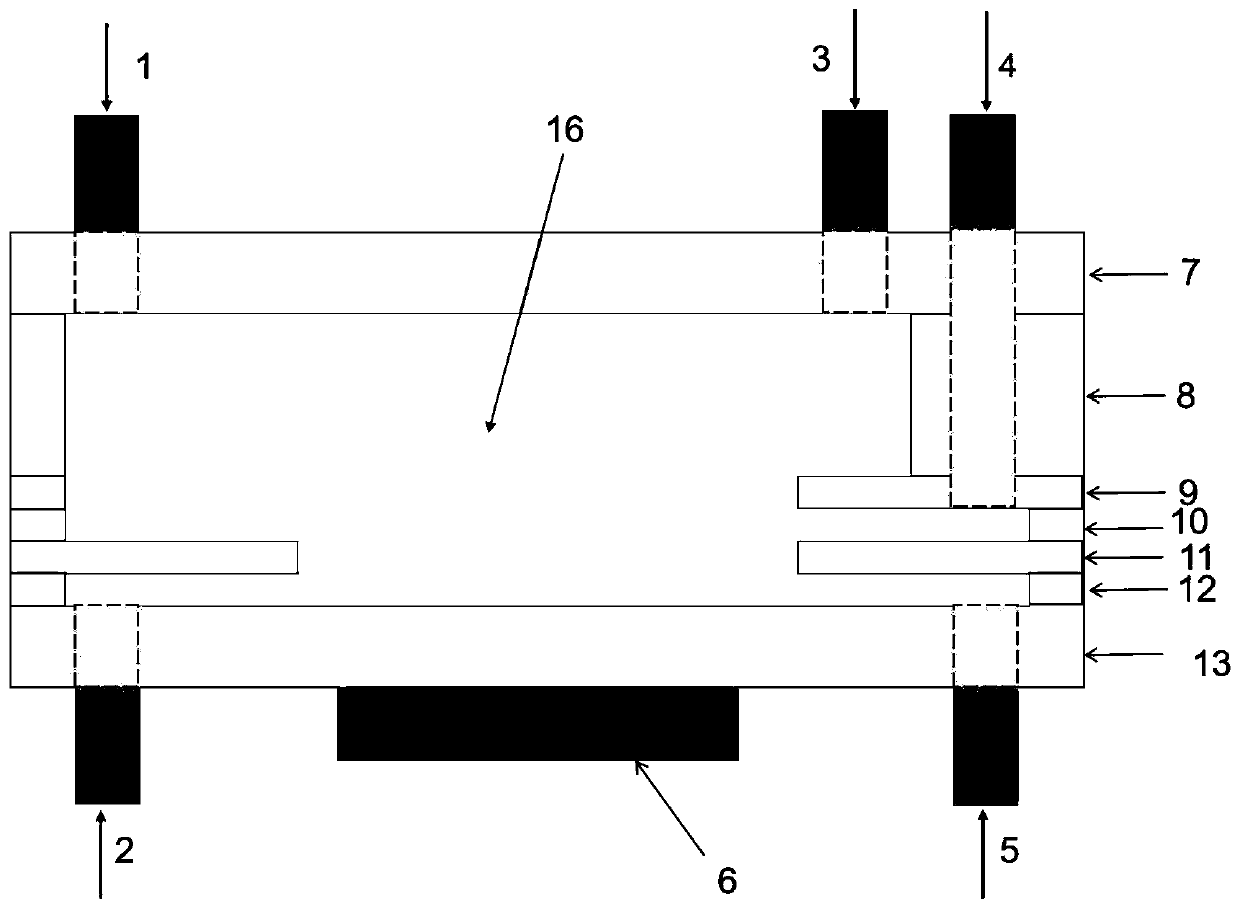

[0044] Preparation of high-throughput microfluidic volume wave sorting chip

[0045] The preparation method is as follows:

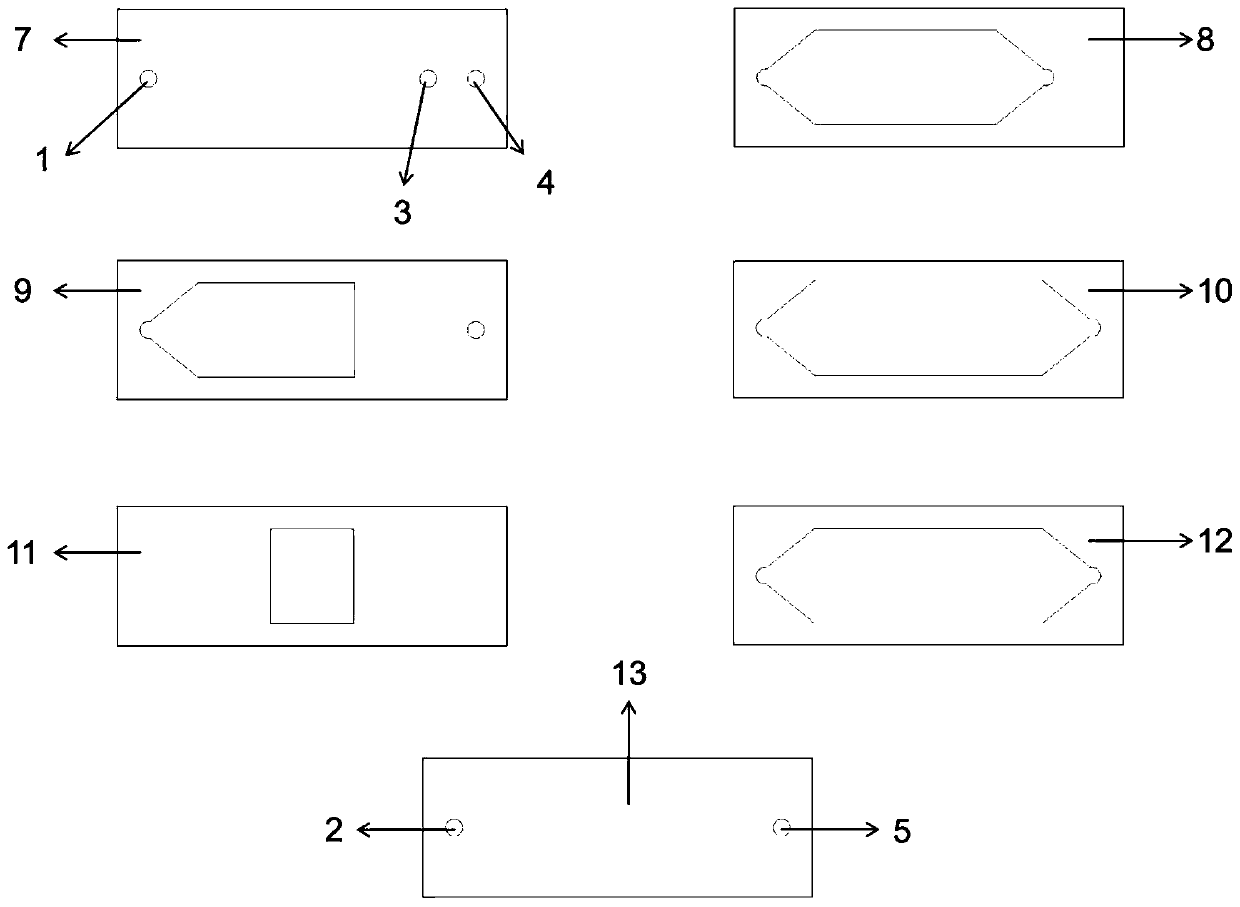

[0046] (1) Use laser cutting glass sheets with different thicknesses to process 7 glass sheets with hollow shape and the same overall size:

[0047] The bottom sheet 13 has a sample inlet I (2) and a sample outlet II (5) at both ends; preferably, the thickness is 1.25mm;

[0048] Gasket I (12), hollowed out in the middle into a hexagonal shape; preferably, the thickness is 150 μm;

[0049] The middle of the spacer I (11) is hollowed out to be a square; preferably, the thickness is 75 μm;

[0050] The spacer II (10) is hollowed out in the middle of a hexagonal shape, which is exactly the same as the spacer I (12) as a whole; preferably, the thickness is 100 μm;

[0051] Separator II (9) left half is hollowed out, and the hollowed out part is a pentagon with an area less than the hexagonal area of gasket I (12), and the right half has a hole leading t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com