Preparation method of highly-transparent Yb<3+> single-doped fluorosilicate microcrystalline glass

A glass-ceramic and fluorosilicate technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of low physical and chemical stability, complicated preparation process of crystal materials, and limited application requirements, etc. The effect of excellent processability, excellent chemical stability, and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] A method for preparing transparent glass-ceramics with strong blue up-conversion luminescent properties at room temperature, comprising the following contents:

[0022] 1. Preparation of matrix glass:

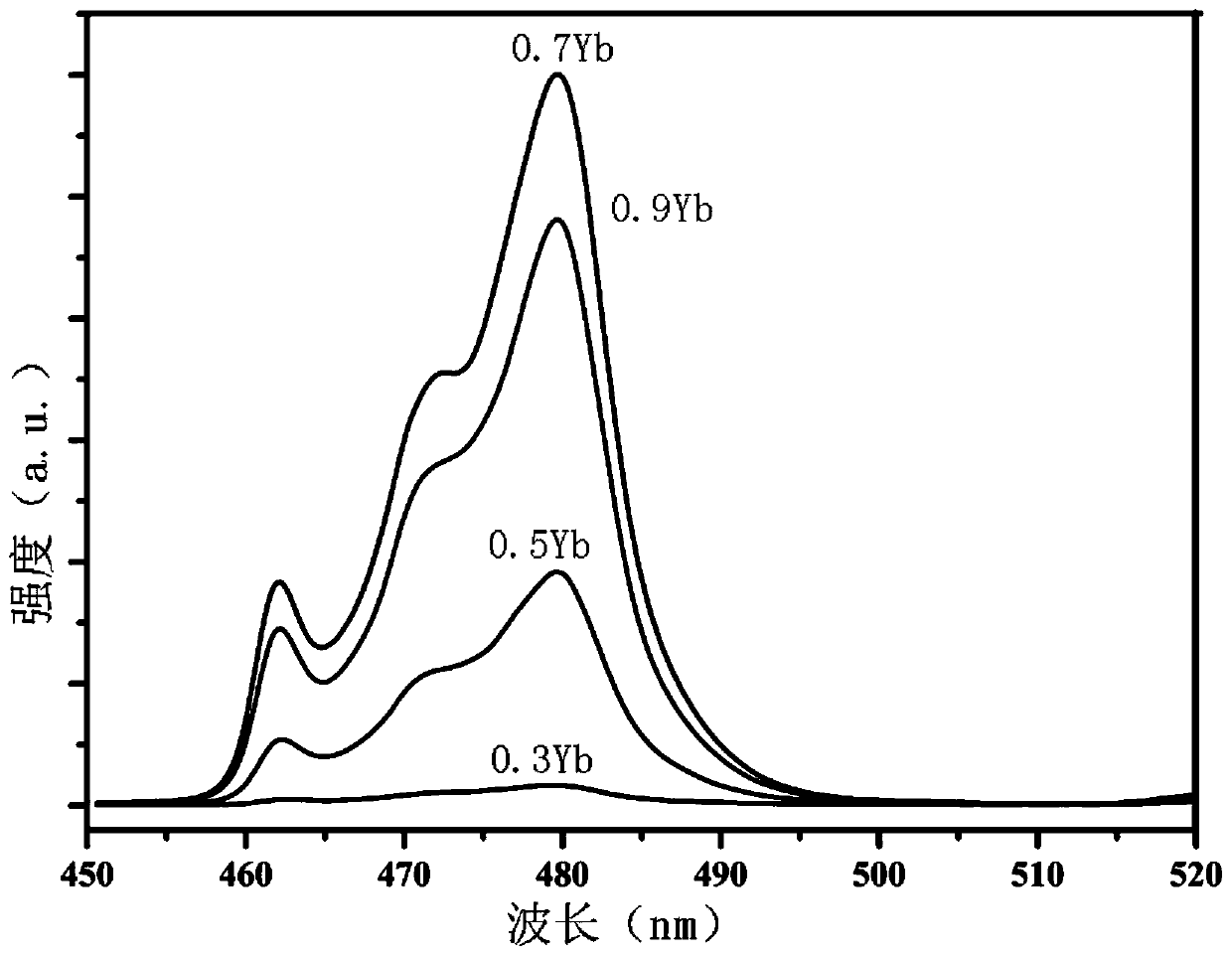

[0023] On the basis of the mole percentage composition of the glass matrix, 0.1-0.9 mol% YbF3 is added. After fully mixing 30 g of the mixture in an agate mortar for 20 minutes, the mixture was put into a platinum crucible, and heated at 1400 degrees Celsius for 20 minutes in an air environment. The molten glass is then poured onto copper molds and pressed into shape. In order to eliminate the stress inside the glass, immediately put the glass into the annealing furnace for annealing at 450°C for 3h.

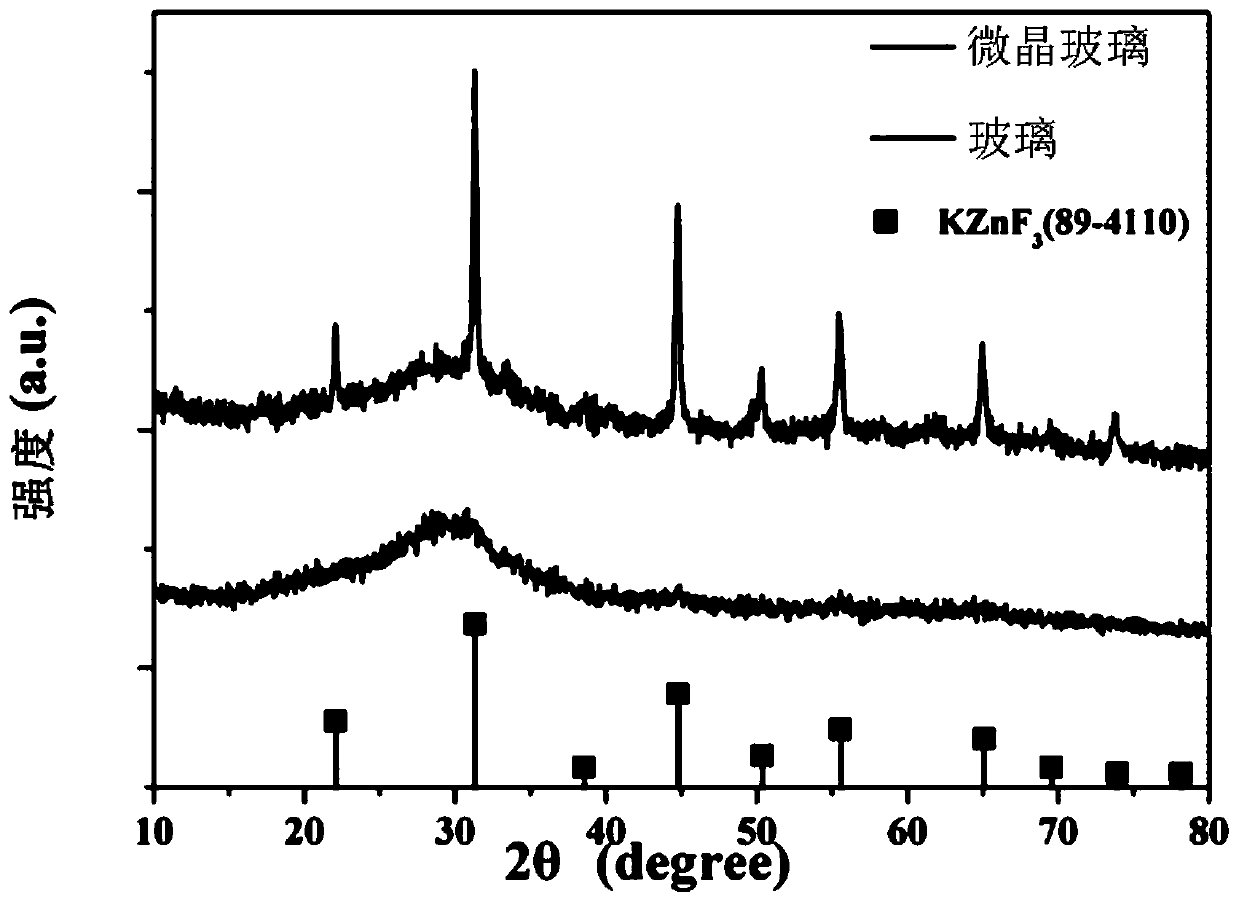

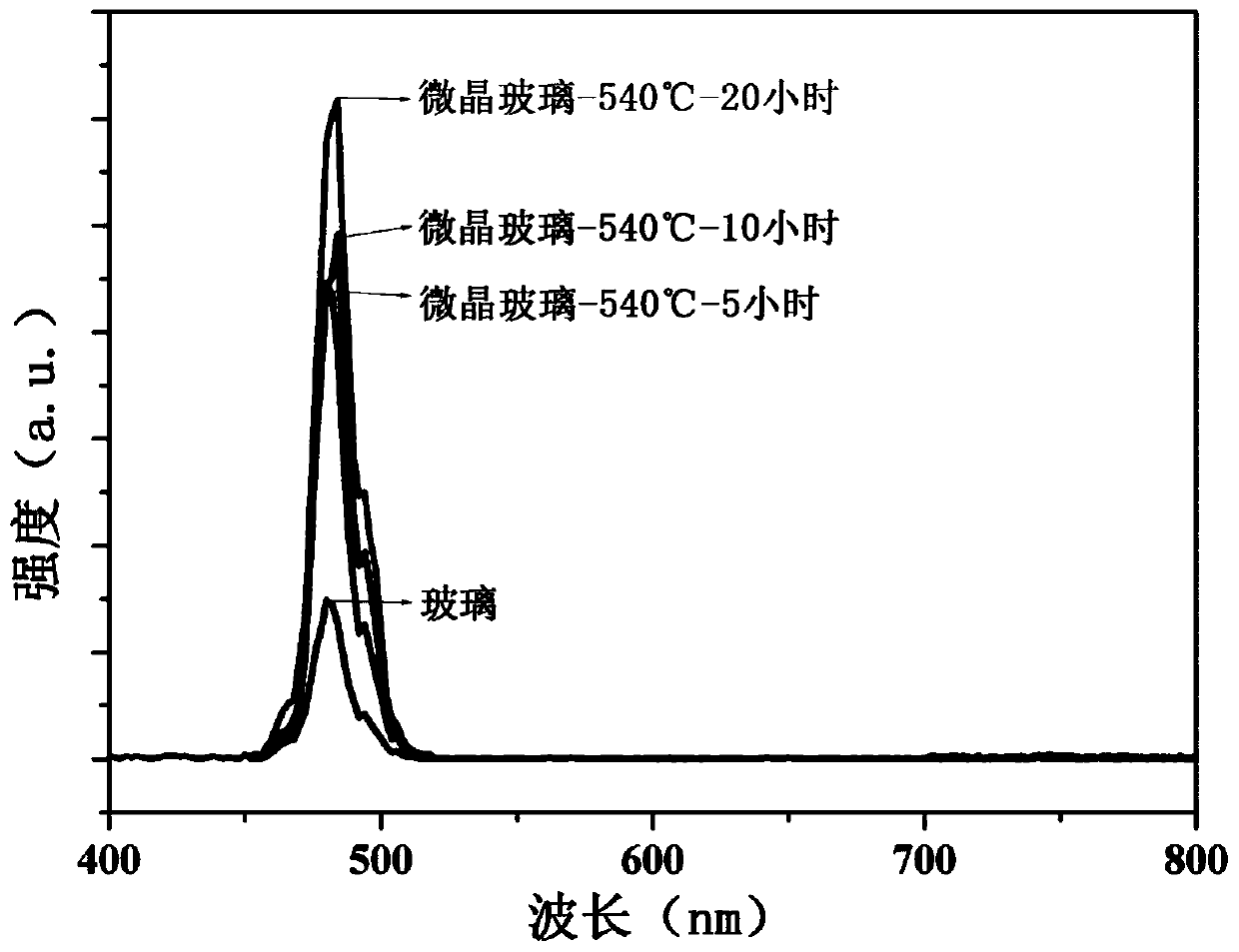

[0024] 2. Preparation of glass-ceramics:

[0025] The annealed glass is reheated for microcrystallization treatment, so that fluoride crystallites with a size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com