Method for increasing finished product rate of AlV55 vanadium-aluminum alloy

A vanadium-aluminum alloy and yield technology is applied in the field of improving the yield of AlV55 vanadium-aluminum alloy, which can solve the problem of low yield of AlV55 alloy, and achieve the effects of reducing the apparent quality of the alloy, no slag sticking, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

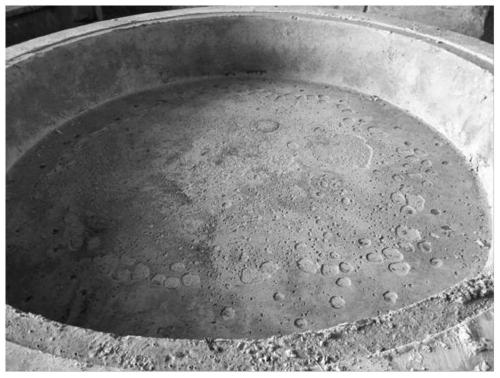

Image

Examples

Embodiment 1

[0049] Weigh high-purity V 2 o 5 (particle size: 120 mesh ~ 160 mesh) 150kg, high-purity metal Al (particle size: 80 mesh ~ 120 mesh) 132.3kg and AlV55 broken alloy (particle size: 5 ~ 10mm, V content 59.1%) 21kg into the material tank and mix evenly Then pour it into the reactor lined with integral casting, ignite the magnesium strip to trigger the reaction, open the reactor after 24 hours, put it into the vacuum induction furnace for remelting and casting after treatment, the vacuum degree is controlled at 10Pa, the maximum temperature is 1510°C, and the melting time After 30 minutes and 24 hours, the vacuum induction furnace was turned on, and an AlV55 alloy with a V content of 59.3% and a yield of 70% was obtained after sand blasting and crushing.

Embodiment 2

[0051] Weigh high-purity V 2 o 5 (particle size: ≤160 mesh) 100kg, high-purity metal Al (particle size: ≤120 mesh) 87.7kg and AlV55 broken alloy (particle size: ≤5mm, V content 59.2%) 13.6kg are put into the material tank and mixed evenly, then poured into the The reactor lined with integral casting, ignites the magnesium tape to trigger the reaction, opens the reactor after 24 hours, and puts it into a vacuum induction furnace for remelting and casting after treatment. The vacuum induction furnace was turned on, and an AlV55 alloy with a V content of 59.1% and a yield of 70.6% was obtained after sand blasting and crushing.

Embodiment 3

[0053] Weigh high-purity V 2 o 5 (particle size: 120 mesh ~ 160 mesh) 200kg, high-purity metal Al (particle size: ≤80 mesh) 176kg and AlV55 broken alloy (particle size: 3 ~ 8mm, V content 59.5%) 27.8kg into the material tank and mix evenly before pouring Into the reactor lined with integral casting, ignite the magnesium strip to trigger the reaction, open the reactor after 24 hours, put it into the vacuum induction furnace for remelting and casting after treatment, the vacuum degree is controlled at 30Pa, the maximum temperature is 1530°C, and the melting time is 50min. After 24 hours, the vacuum induction furnace was turned on, and an AlV55 alloy with a V content of 59.4% and a yield of 71.5% was obtained after sand blasting and crushing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com