Environment-friendly assembled large-scale pig farm and construction method thereof

A prefabricated pig farm technology, applied in the field of agriculture, animal husbandry and breeding, can solve the problems of heavy workload, long construction period, and high labor intensity of workers, and achieve the effect of short cycle, low construction cost and strong reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with embodiment the specific embodiment of the present invention is described in further detail:

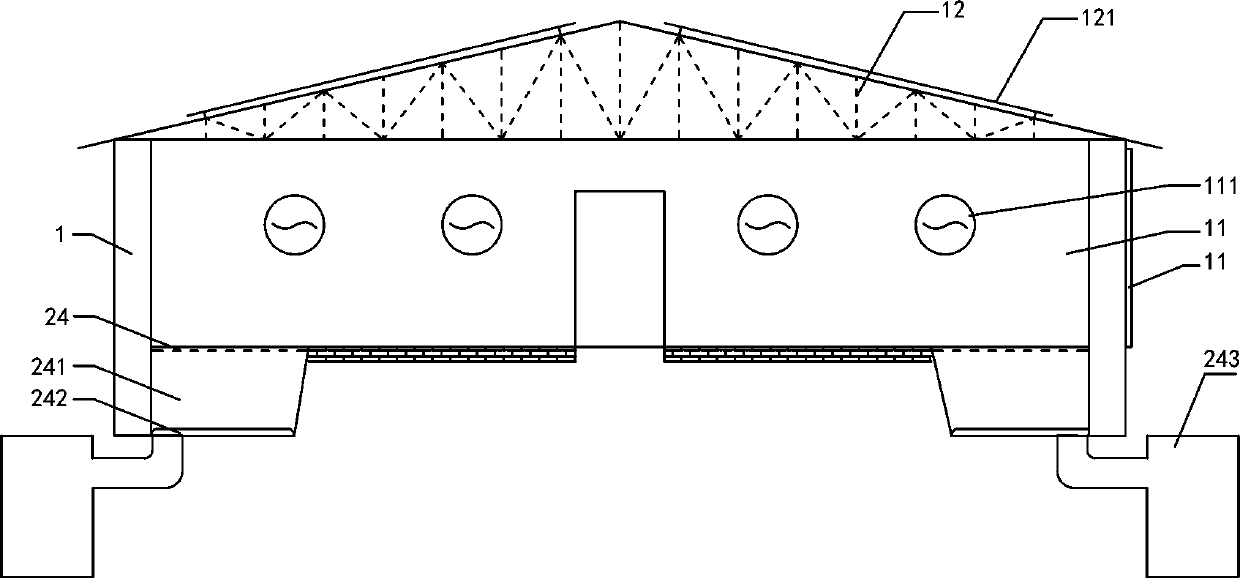

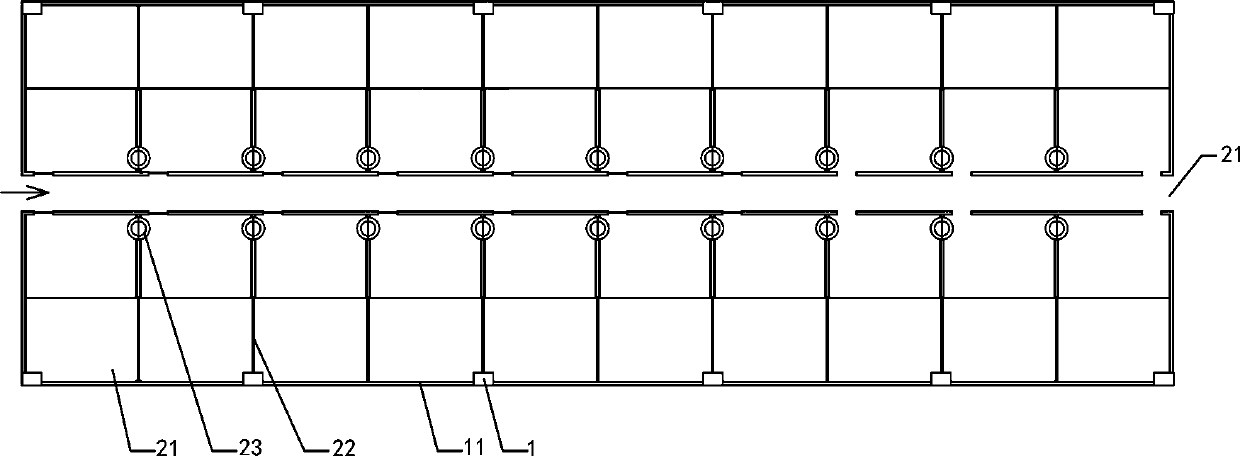

[0039] Such as figure 1 with figure 2 As shown, an environmentally friendly assembled large-scale pig farm includes a main structure 1 provided with a feeding room 21 and breeding equipment; the main structure 1 is sequentially provided with a roof truss 12, a breeding area, and a waste collection area from top to bottom. An enclosure 11 is provided on the outside of the structure 1, and the enclosure 11 is composed of thermal insulation materials;

[0040] The roof truss 12 is arranged on the top of the main structure 1, and the top of the roof truss 12 is provided with a photovoltaic power generation module 121. The main structure 1 and the roof truss 12 are connected by light steel thin-walled or cement prefabricated components; the photovoltaic power generation module 121 is arranged symmetrically in two pieces The distributed photovoltaic power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com