A Method for Efficiently Preparing Fat-derived Biomaterials Using Ultrasound

A biomaterial and ultrasonic technology, applied in the field of regenerative medicine, can solve the problems of cytokine loss, cumbersome operation, and long time consumption, and achieve the effect of improved cell activity, low preparation cost, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

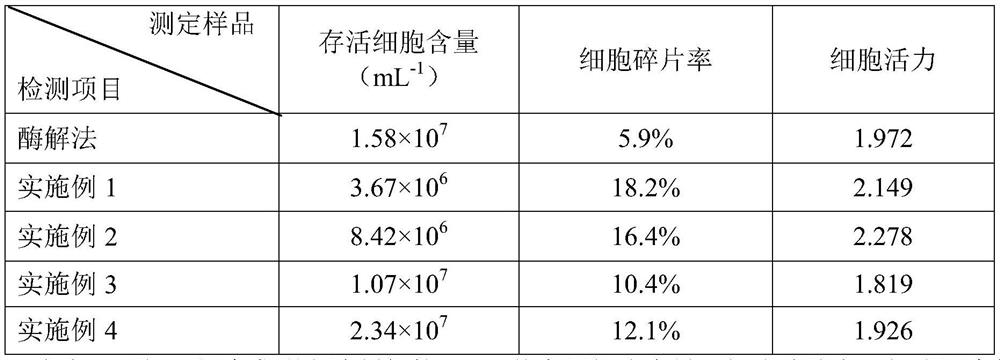

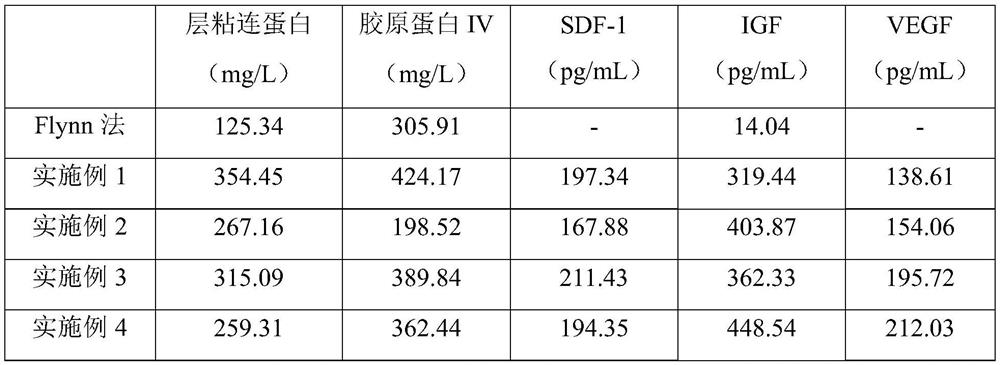

Examples

Embodiment 1

[0049] A method for efficiently preparing fat-derived biological materials by using ultrasonic waves, the specific steps are as follows:

[0050] (1) Centrifuge the adipose tissue at 5000rpm for 3 minutes. After centrifugation, if it is divided into three layers, namely the top layer of fat, the middle layer of mixture and the bottom layer of swelling fluid, discard the bottom layer of swelling fluid, filter to remove the top layer of fat and take the filtrate; if If there is no delamination or the delamination is not obvious, repeat this step;

[0051] (2) performing non-contact ultrasonic crushing on the filtrate obtained in step (1), the ultrasonic crushing conditions being 1000W, 10min, 36°C;

[0052] (3) centrifuging the fat mixture after step (2) non-contact ultrasonic crushing at 5000rpm for 5min;

[0053] (4) After centrifugation in step (3), if the fat mixture is divided into three layers, which are the top layer of fat, the middle layer of mixture and the bottom swe...

Embodiment 2

[0058] A method for efficiently preparing fat-derived biological materials by using ultrasonic waves, the specific steps are as follows:

[0059] (1) Centrifuge the adipose tissue at 5500rpm for 3 minutes. After centrifugation, if it is divided into three layers, namely the top layer of fat, the middle layer of mixture and the bottom layer of swelling fluid, discard the bottom layer of swelling fluid, filter to remove the top layer of fat and take the filtrate; if If there is no delamination or the delamination is not obvious, repeat this step;

[0060] (2) The filtrate obtained in step (1) is subjected to non-contact ultrasonic crushing, and the ultrasonic crushing conditions are 1100W, 9min, 36°C;

[0061] (3) centrifuging the fat mixture after step (2) non-contact ultrasonic crushing at 5000rpm for 6min;

[0062] (4) After centrifugation in step (3), if the fat mixture is divided into three layers, which are the top layer of fat, the middle layer of mixture and the bottom ...

Embodiment 3

[0067] A method for efficiently preparing fat-derived biological materials by using ultrasonic waves, the specific steps are as follows:

[0068] (1) Centrifuge the adipose tissue at 6000rpm for 3 minutes. After centrifugation, if it is divided into three layers, namely the top layer of fat, the middle layer of mixture and the bottom layer of swelling fluid, discard the bottom layer of swelling fluid, filter to remove the top layer of fat and take the filtrate; If there is no delamination or the delamination is not obvious, repeat this step;

[0069] (2) The filtrate obtained in step (1) is subjected to non-contact ultrasonic crushing, and the ultrasonic crushing conditions are 1150W, 5min, and 36.5°C;

[0070] (3) centrifuging the fat mixture after step (2) non-contact ultrasonic crushing at 5000rpm for 4min;

[0071] (4) After centrifugation in step (3), if the fat mixture is divided into three layers, which are the top layer of fat, the middle layer of mixture and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com