Cell culture composite film and preparation method and application thereof

A cell culture and composite membrane technology, applied in tissue cell/virus culture devices, biochemical equipment and methods, and other household appliances, etc., can solve problems such as economic loss, expensive biological products, membrane damage and leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention adopts multi-layer co-extrusion to prepare the multi-layer film whose extruded thickness is 300um, and its structural composition of this multi-layer film:

[0027] The outermost layer of PEEK with a thickness of 50um is 450G produced by VICTREX Company, its density is 1.26g / cm3, water absorption: 0.07%, test conditions: 23°C, 24hr, 3.20mm, test method: ISO62); Bending strength: 165MPa, test condition: 23℃, test method: ISO178); tensile stress: 100MPa, test condition: yield, 23℃, test method: ISO527-2); tensile strain: 45MPa, test condition: fracture, 23°C, test method: ISO527-2).

[0028] Oxygen barrier layer EVOH with a thickness of 50um, which is F171 produced by Kuraray Corporation of Japan, has a density of 1.19g / cm3, an ethylene content of 32%, and elongation at break: 14.4% (test method: ISO-527), Water vapor transmission rate: 40-80g*30u / m 2 *24hrs, test conditions: 40℃, 90%RH; oxygen transmission rate: 0.4cm3*20u / m 2 *24hrs*atm, test co...

Embodiment 2

[0034] The present invention adopts the multi-layer film prepared by multi-layer co-extrusion, and its structural composition of this multi-layer film:

[0035] The outermost layer of PEEK with a thickness of 10um, which is 450G produced by VICTREX company, has a density of 1.26g / cm3, water absorption: 0.07%, test conditions: 23°C, 24hr, 3.20mm, test method: ISO62); Bending strength: 165MPa, test condition: 23℃, test method: ISO178); tensile stress: 100MPa, test condition: yield, 23℃, test method: ISO527-2); tensile strain: 45MPa, test condition: fracture, 23°C, test method: ISO527-2).

[0036] Oxygen barrier EVOH with a thickness of 15um, which is produced by Kuraray Corporation of Japan is F171, with a density of 1.19g / cm3, an ethylene content of 32%, and elongation at break: 14.4% (test method: ISO-527), Water vapor transmission rate: 40-80g*30u / m 2 *24hrs, test conditions: 40℃, 90%RH; oxygen transmission rate: 0.4cm3*20u / m 2 *24hrs*atm, test conditions: 20°C, 65%RH.

...

Embodiment 3

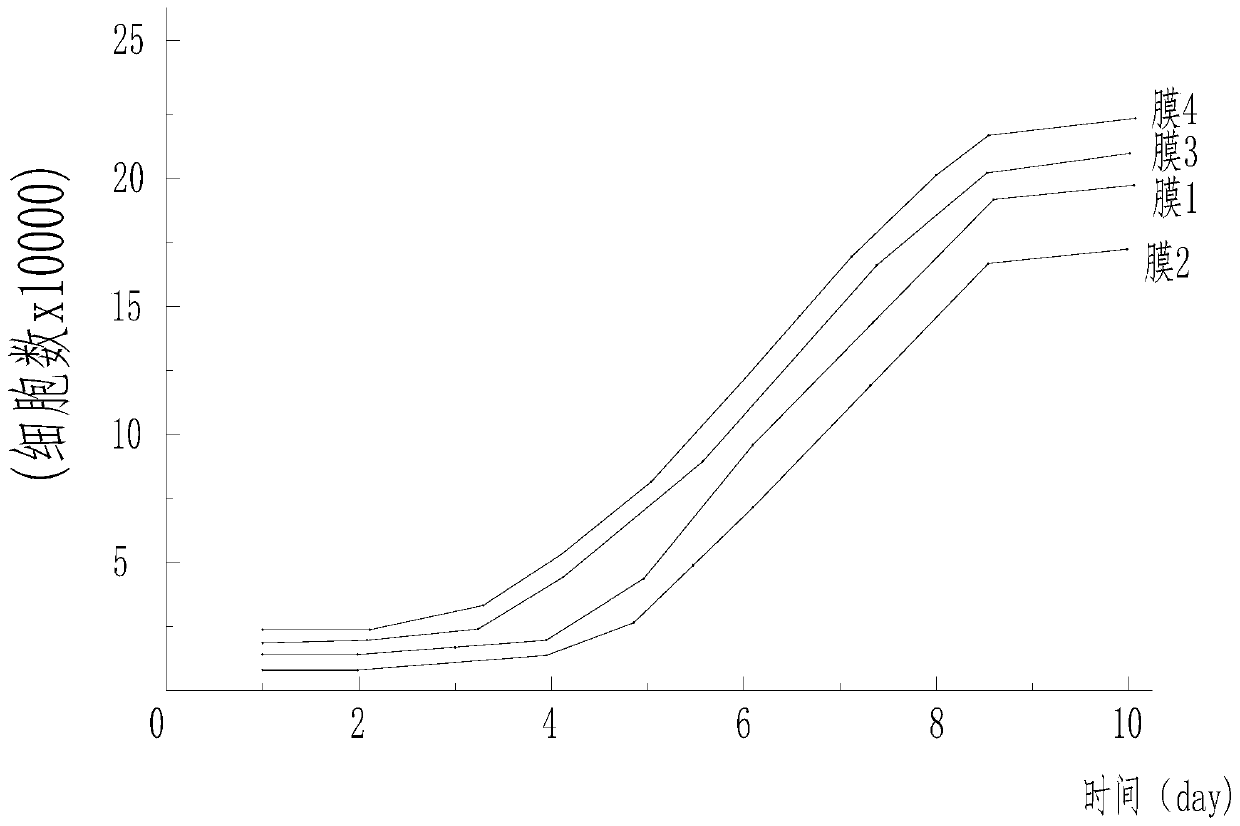

[0041] Embodiment 3: mechanical stress experiment

[0042] Equipment: Swing test bag tightness

[0043] The 2D bag prepared with the multilayer film (code A) of Example 1 and having a volume of 25 liters is filled with 25 liters of water and placed on a motion platform that swings left and right, with a swing angle of plus or minus 12° and a speed of 45 r / min, run until leak, test for fluid coming out of the bag.

[0044] The test is the same as film No. A under the same conditions, except that the same 2D bag is prepared from the commercially available pureflex multilayer film (No. B) of the American millipore company, and the test conditions are exactly the same.

[0045] The test is the same as film No. A under the same conditions, except that the same 2D bag is prepared from the commercially available flexsafe multilayer film (No. C) of German company Sartorious, and the test conditions are exactly the same.

[0046] The test is the same as the film No. A under the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com