Processing method of binary transition metal oxide film nanometer patterns

A technology of oxide thin films and transition metals, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve problems such as probe physical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

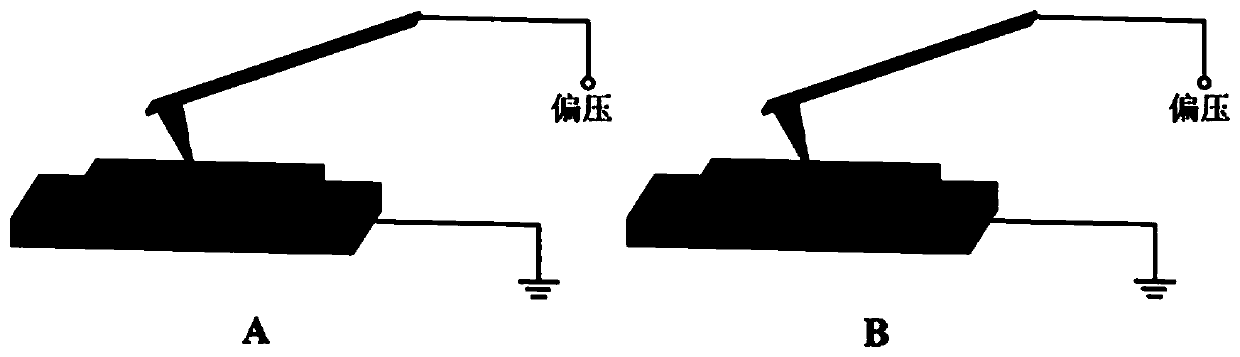

[0028] The first embodiment of the present invention is to perform single-point nanopattern processing on the binary transition metal oxide thin film under the condition of fixing the voltage amplitude applied by the probe. The schematic diagram of the processing is as follows figure 1 Shown in (A), its concrete mode of operation is:

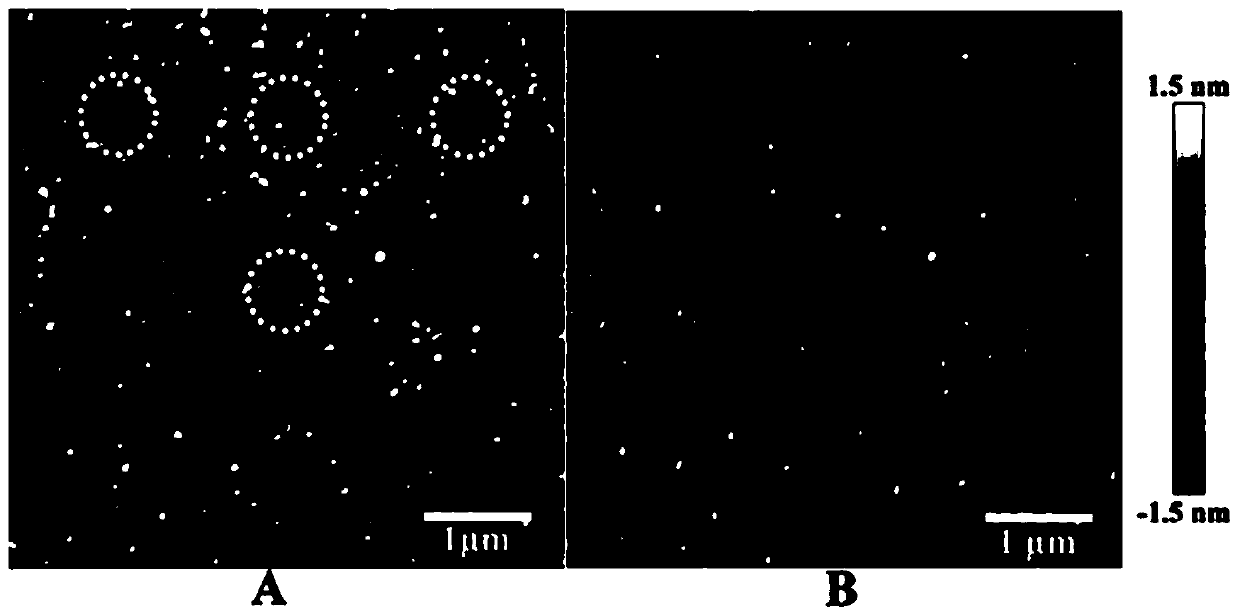

[0029] 1. If figure 2 As shown in (A), use the AFM tapping mode to scan a rectangular surface of 5 μm × 5 μm in the sample, and then select four points. The center position of the four white dotted circles is the position of the point where the probe tip contacts the sample during single-point processing.

[0030] 2. Switch the topography scanning mode of the C-AFM system to the contact mode.

[0031] 3. Accurately touch the probe tip to the selected four points, and apply a DC bias voltage of 0V-6V to the probe tip at the four points for 5, 20, 60, and 85 times respectively.

[0032] The following are the results of four specific processing...

Embodiment 2

[0039] The second embodiment of the present invention is to perform single-point nanopattern processing on the binary transition metal oxide thin film under the condition of fixing the number of voltages applied to the probe. The schematic diagram of the processing is as follows figure 1 Shown in (A), its concrete mode of operation is:

[0040] 1. If Figure 5 As shown in (A), use the AFM tapping mode to scan a rectangular surface of 10 μm × 10 μm in the sample, and then select three points. The position of the center of the three white dotted circles is the position of the point where the probe tip contacts the sample during single-point processing.

[0041] 2. Switch the topography scanning mode of the C-AFM system to the contact mode.

[0042] 3. Accurately touch the probe tip to the selected three points, and apply DC bias voltages of 0V-6V, 0V-8V, and 0V-10V respectively to the probe tip 50 times at the three points.

[0043] The following are the results of three spec...

Embodiment 3

[0048] The third embodiment of the present invention is to process nano-patterns of binary transition metal oxide films by scanning the surface of the powered probe, and the processing schematic diagram is as follows figure 1 Shown in (B), its specific mode of operation is:

[0049] 1. Use a C-AFM and apply a 10V DC bias to the probe tip.

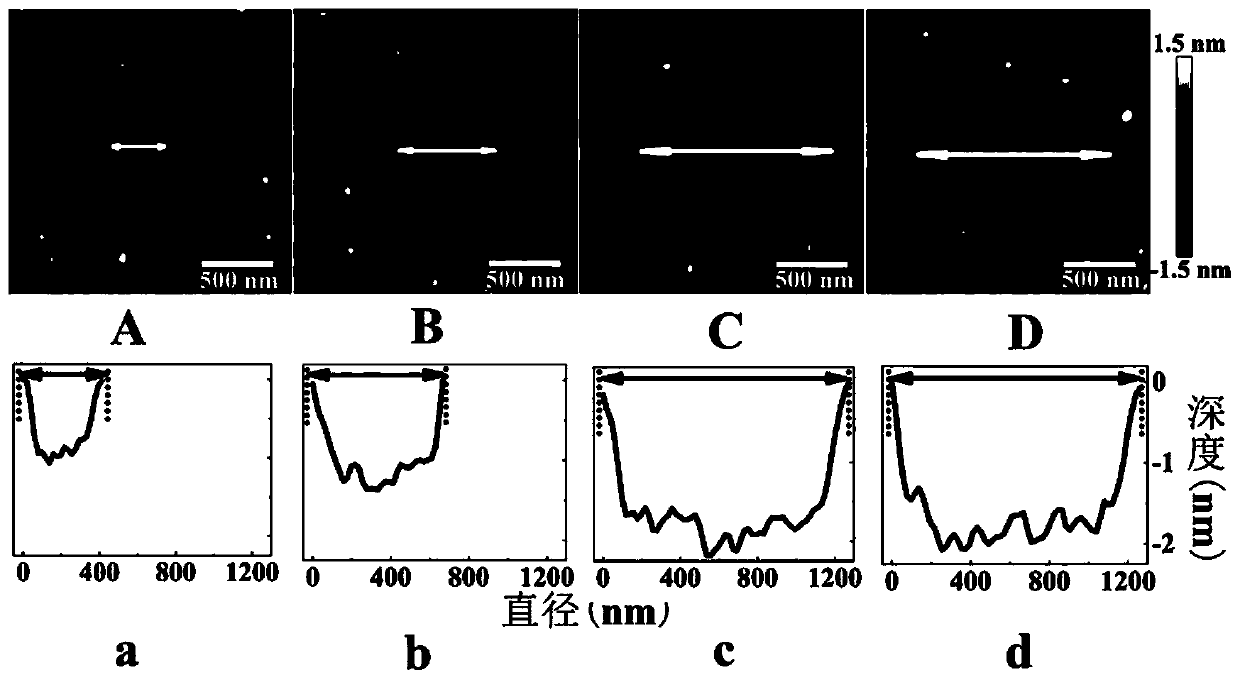

[0050] 2. If Figure 7 As shown, a rectangular area of 1 μm × 1 μm was scanned using the C-AFM contact mode, and the scanning times were 5 and 15 times, respectively.

[0051] The following are the results of two specific processing tests carried out using the method of this example:

[0052] Figure 8 The AFM topography diagrams of the circular nano-pits processed on the surface of the hafnium oxide film for the two specific processing tests of this embodiment and the corresponding diameter and depth diagrams of the circular nano-pits. Among them, the sub-graphs A and B are the AFM morphology of the circular nano-pits processed by sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com