High-nickel ternary positive electrode material coated with fast ion conductor, preparation method thereof, and lithium ion battery prepared from material

A technology of lithium-ion batteries and ion conductors, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of poor conductivity and inability to provide enough channels for lithium ion migration, so as to reduce residual lithium and suitably Suitable for large-scale production and high capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

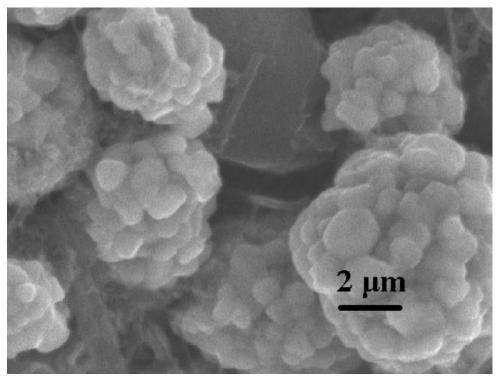

Image

Examples

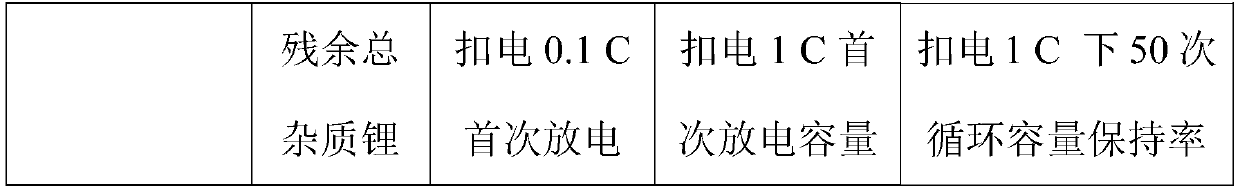

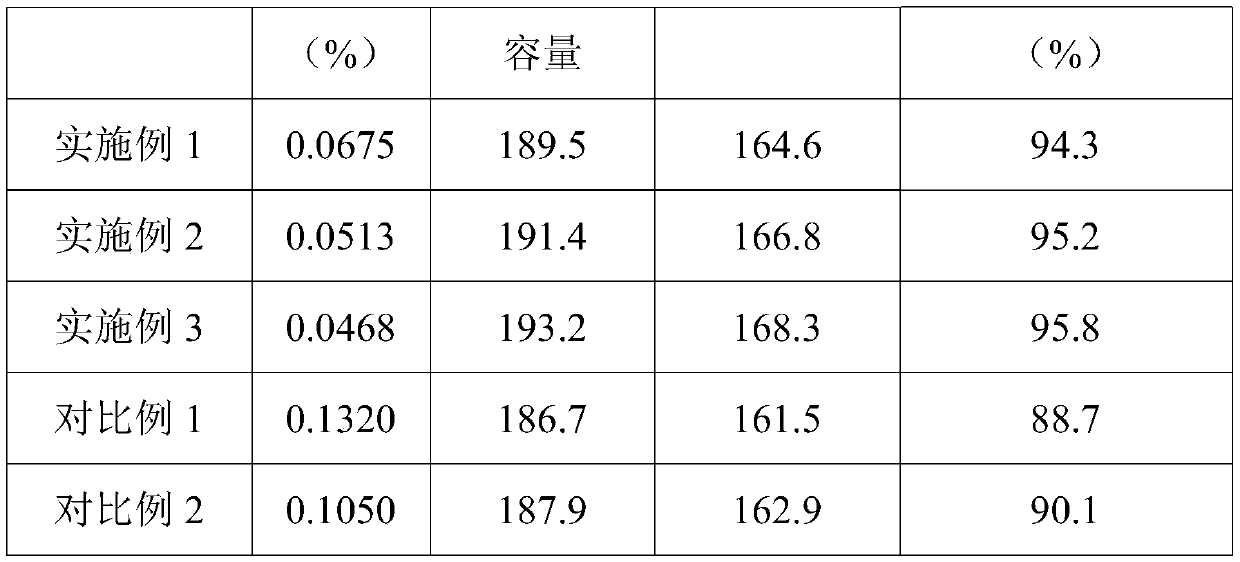

Embodiment 1

[0038] A method for preparing a high-nickel ternary cathode material coated by a fast ion conductor, comprising the following steps:

[0039] (1) Synthesis of nickel cobalt manganese hydroxide precursor;

[0040] (1-1) nickel nitrate, cobalt nitrate and manganese nitrate are dissolved in deionized water according to the stoichiometric ratio of 8:1:1,

[0041] A salt solution I was obtained; the total concentration of the three metal salts in the solution I was 2.0 mol / L.

[0042] (1-2) Dissolving KOH powder in deionized water to obtain precipitant solution II; the concentration of KOH in the precipitant solution II is 6mol / L.

[0043](1-3) Mix ammonia water and deionized water to obtain complexing agent solution III; the concentration of ammonia water in the complexing agent solution III is 2mol / L.

[0044] (1-4) Inject the salt solution I, the precipitant solution II and the complexing agent solution III into the reaction kettle at the same time and mix them, and pass nitro...

Embodiment 2

[0052] A method for preparing a high-nickel ternary cathode material coated by a fast ion conductor, comprising the following steps:

[0053] (1) Synthesis of nickel cobalt manganese hydroxide precursor;

[0054] (1-1) Nickel chloride, cobalt chloride and manganese chloride are dissolved in deionized water according to the stoichiometric ratio of 7:1.5:1.5 to obtain salt solution I; the total concentration of the three metal salts in the solution I is 2.0mol / L.

[0055] (1-2) Sodium hydroxide powder was dissolved in deionized water to obtain precipitant solution II; the concentration of sodium hydroxide in the precipitant solution II was 6 mol / L.

[0056] (1-3) Sodium citrate is mixed with deionized water to obtain complexing agent solution III; the concentration of sodium citrate in the complexing agent solution III is 3mol / L.

[0057] (1-4) Inject the salt solution I, the precipitant solution II and the complexing agent solution III into the reaction kettle at the same tim...

Embodiment 3

[0062] A method for preparing a high-nickel ternary cathode material coated by a fast ion conductor, comprising the following steps:

[0063] (1) Synthesize nickel cobalt manganese hydroxide precursor according to the same method as in Example 1;

[0064] (2) the nickel cobalt manganese hydroxide precursor that step (1) obtains and lithium hydroxide powder, Al 2 o 3 powder, MgO powder and TiO 2 Powder mixing, nickel cobalt manganese hydroxide precursor and lithium hydroxide powder, (Al 2 o 3 +MgO+TiO 2 ) with a molar ratio of 1:1.06:0.08, high-speed ball milling and mixing for 5 hours, and then calcining the mixture at 850° C. for 15 hours in an oxygen atmosphere to obtain a high-nickel ternary positive electrode material doped with Al, Mg and Ti;

[0065] (3) The fast ion conductor Li 1.5 al 0.5 sn 1.5 (PO 4 ) 3 Ball milled into powder, then mixed with Al, Mg and Ti-doped high-nickel cathode material for 5 hours, Al, Mg and Ti-doped high-nickel cathode material and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com