Sewage deep purification method

A technology for deep purification and sewage, which is applied in the direction of chemical instruments and methods, separation methods, water/sewage multi-stage treatment, etc. It can solve the problems of large floor area, high operating costs, and inability to achieve low operating costs and high water output. The effect of high water quality and less land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

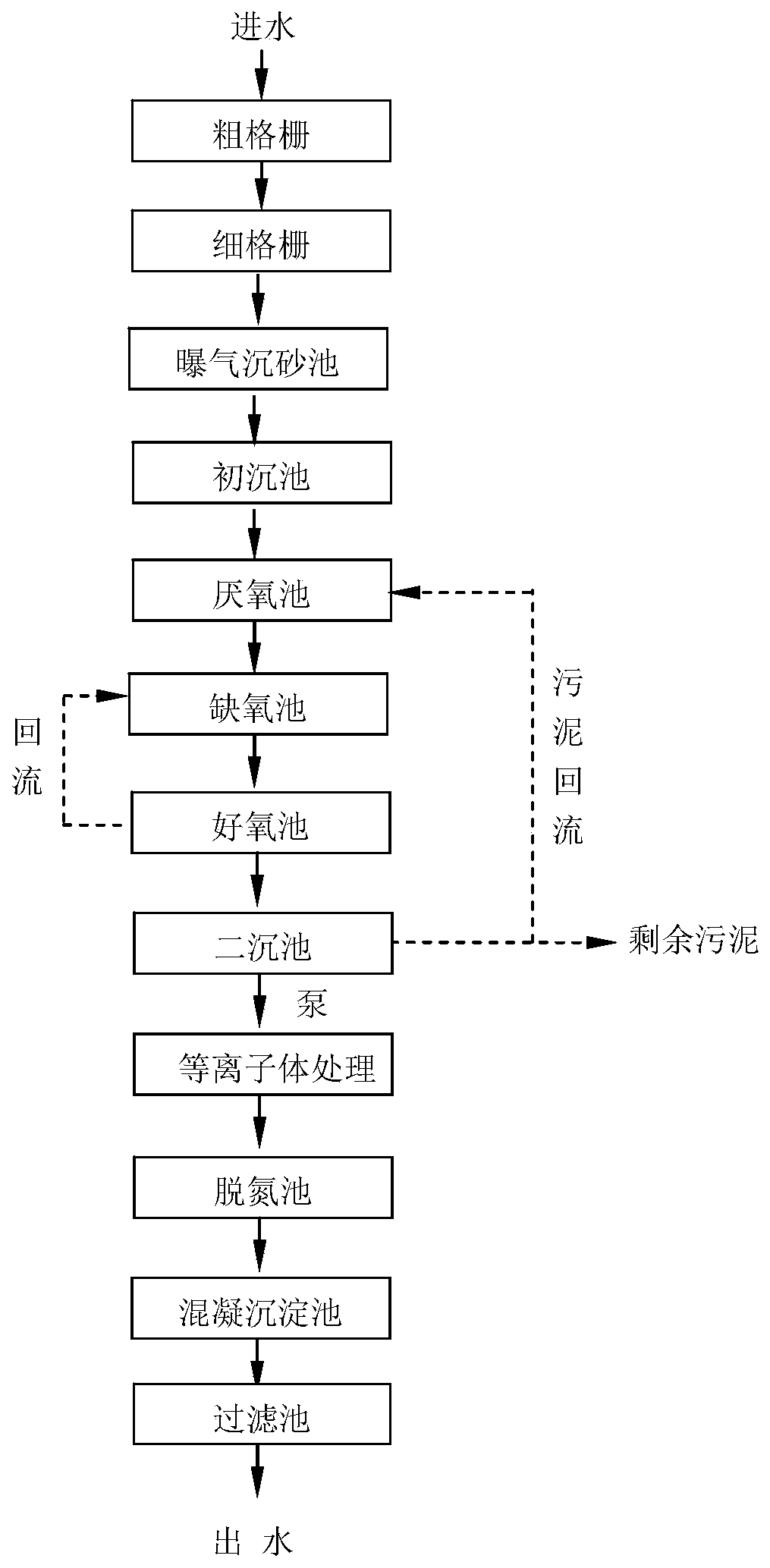

[0033] Embodiment one, with reference to figure 1 , the embodiment of a certain sewage treatment plant, the influent water quality index of described sewage is as table 2.

[0034] Table 2. Influent water quality indicators of a sewage treatment plant

[0035] serial number

Basic Control Items

Measured value (mg / L)

1

COD

400

2

BOD

180

3

SS

300

4

animal and vegetable oil

-

5

Petro

-

6

anionic surfactant

7

Total Nitrogen (as N)

55

8

40

9

Total phosphorus (calculated as P)

7

10

Chroma (dilution factor)

11

pH

6-9

[0036] use figure 1 The deep purification and recycling process of sewage based on A2O and plasma technology, the steps are as follows:

[0037] 1. Primary treatment

[0038] After the sewage is collected, it is filtered through coarse and fine screens, and th...

Embodiment 2

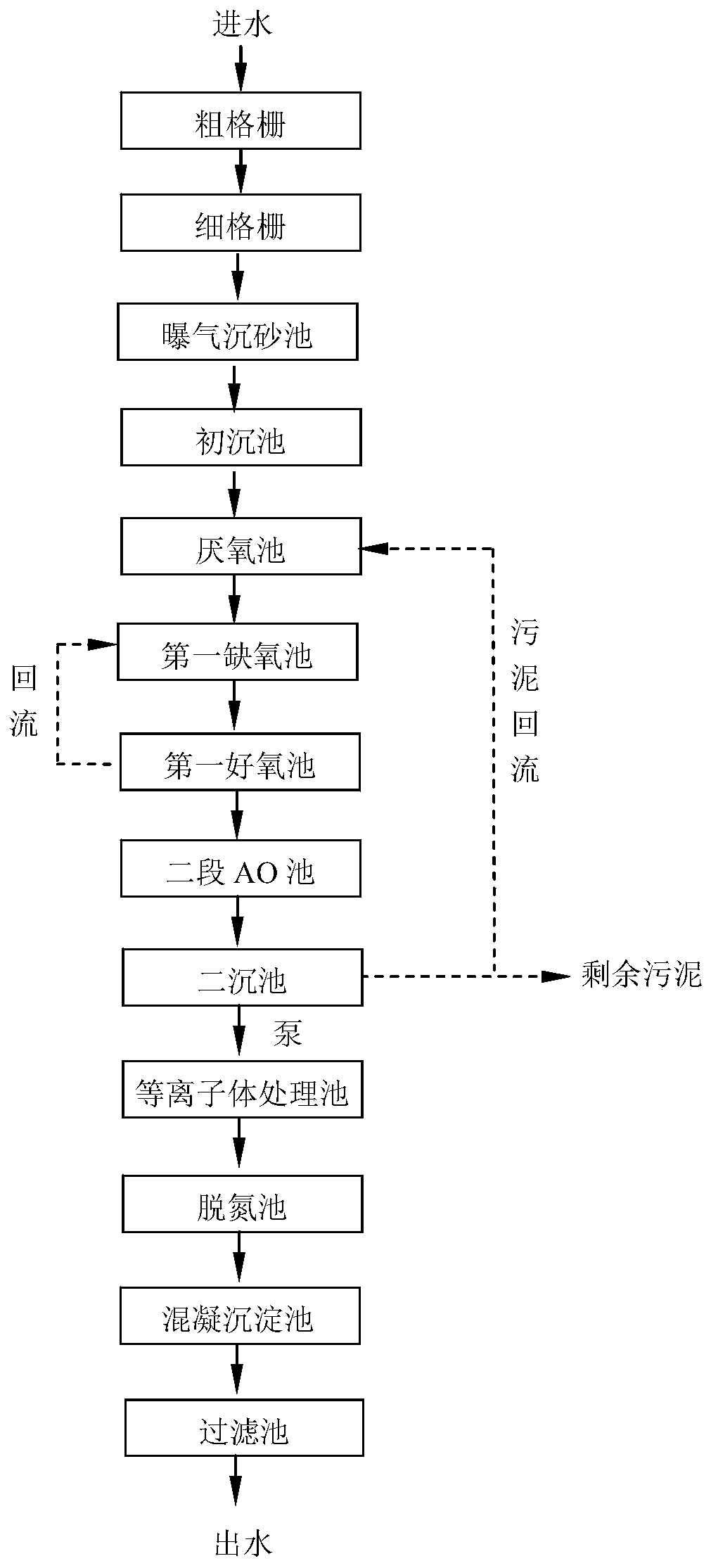

[0059] refer to figure 2 , the embodiment of a certain improved A2 / O and plasma technology sewage deep purification process sewage treatment plant, the influent water quality index of described sewage is as table 4.

[0060] Table 4. Influent water quality of a sewage treatment plant

[0061] serial number

project

Measured value (mg / L)

1

COD

690

2

BOD

370

3

SS

300

4

animal and vegetable oil

-

5

Petro

-

6

anionic surfactant

-

7

Total Nitrogen (as N)

75

8

Ammonia nitrogen (as N)

57

9

Total phosphorus (calculated as P)

8

10

Chroma (dilution factor)

11

pH

6-8

[0062] Due to the high depth of influent pollutants, the figure 2 Advanced biochemical and plasma technology for advanced sewage treatment and recycling process, the steps are as follows:

[0063] 1. Primary treatment

[0064] After t...

Embodiment 3

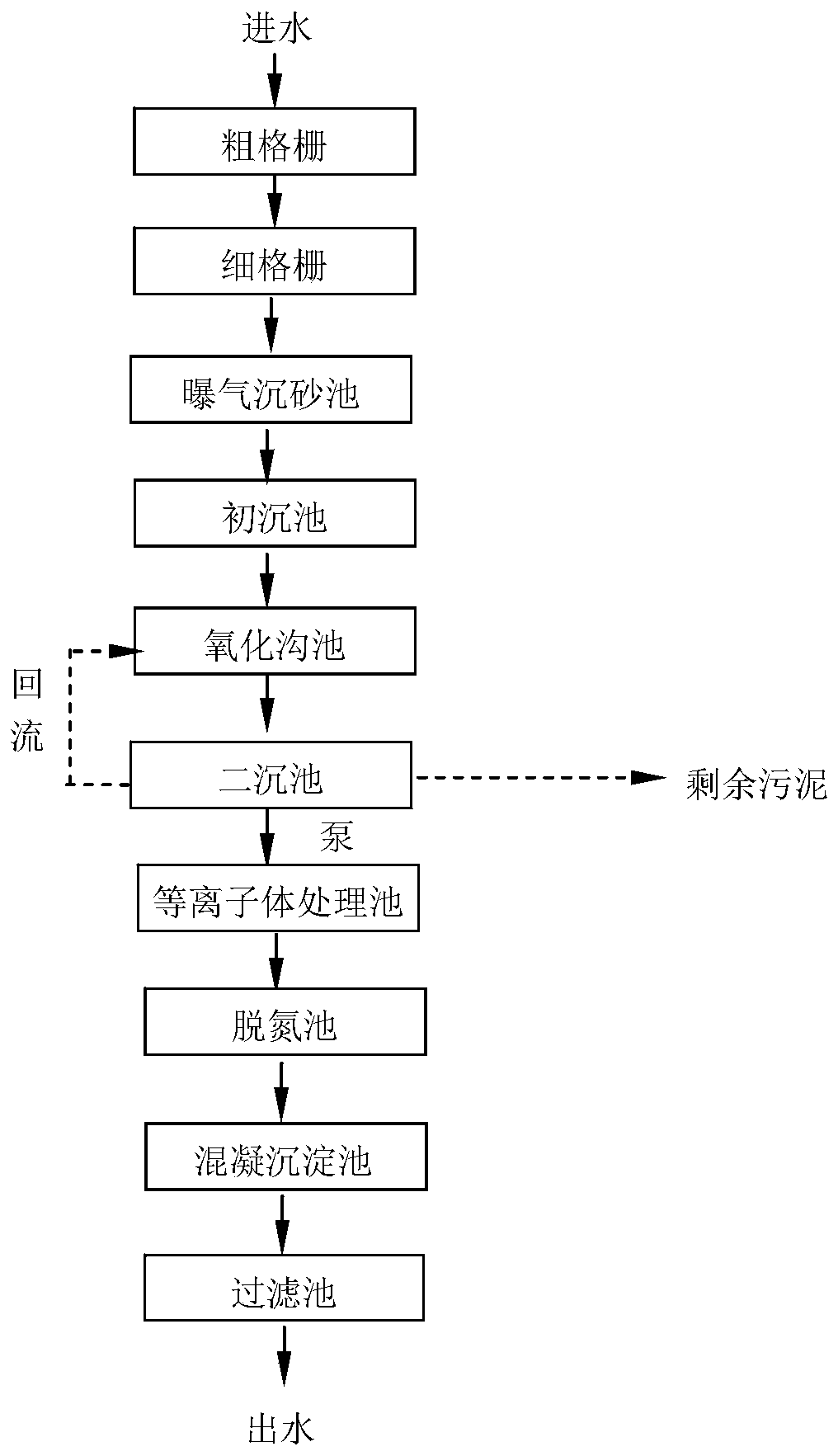

[0084] refer to image 3 , an embodiment of a sewage treatment plant using oxidation ditch and plasma technology, including coarse grids, fine grids, aerated grit chambers, primary sedimentation tanks, oxidation ditch, secondary sedimentation tanks, lift pumps, plasma treatment, Denitrification tank, coagulation sedimentation tank, V-shaped filter tank and other facilities, after treatment, the discharged water will meet the relevant water quality standards of the "Environmental Quality Standards for Surface Water" (GB3838-2002).

[0085] The sewage inflow indicators are shown in Table 6.

[0086] Table 6. Influent water quality indicators of a sewage treatment plant

[0087] serial number

Basic Control Items

Measured value (mg / L)

1

COD

341

2

BOD

192

3

SS

230

4

animal and vegetable oil

-

5

Petro

-

6

anionic surfactant

-

7

Total Nitrogen (as N)

68

8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com