High-intensity solubilizing liquid accelerator and preparation method thereof

An accelerator and liquid technology, applied in the field of building materials, can solve the problems of low production concentration, poor stability, easy delamination, etc., and achieve the effects of reducing transportation costs, improving stability, and improving comprehensive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

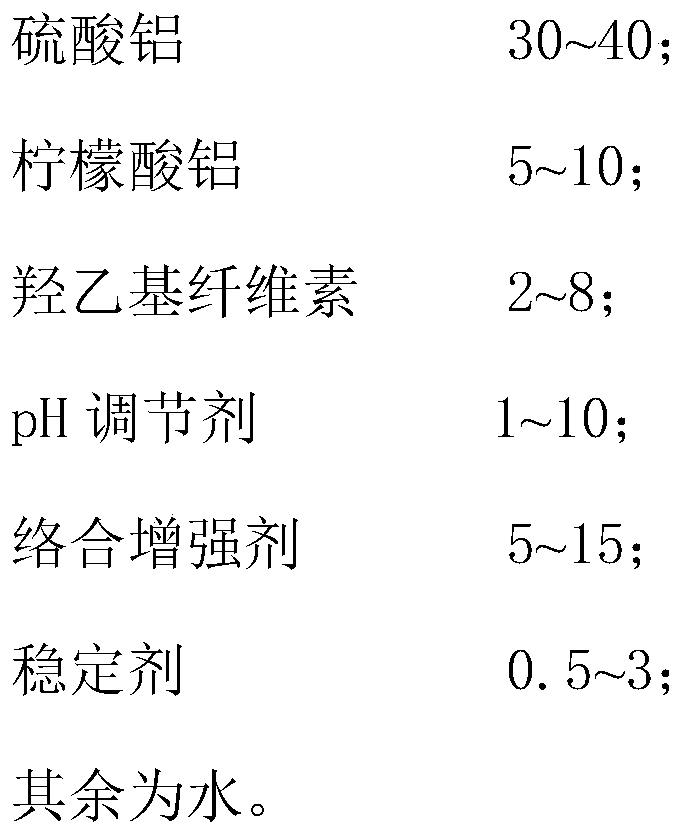

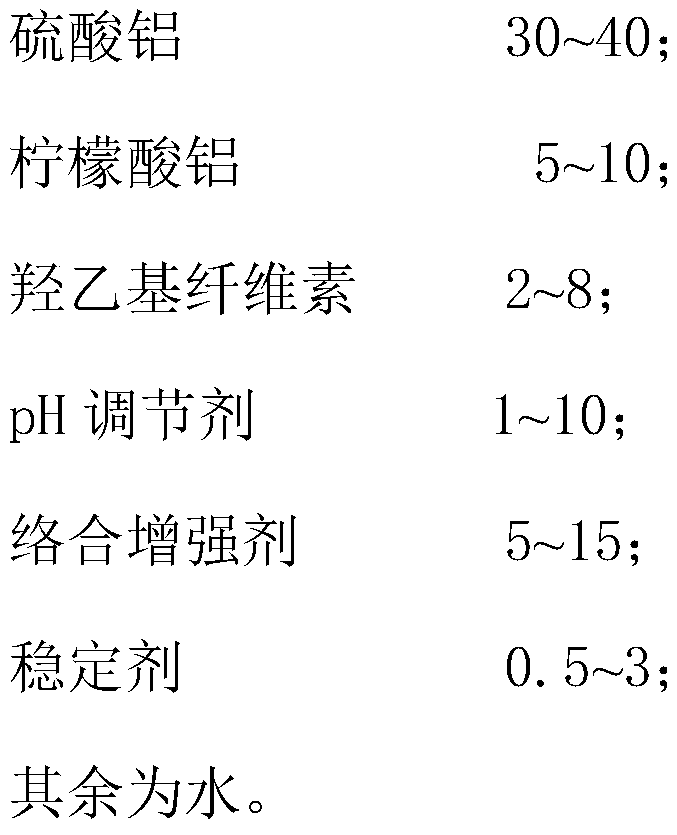

Method used

Image

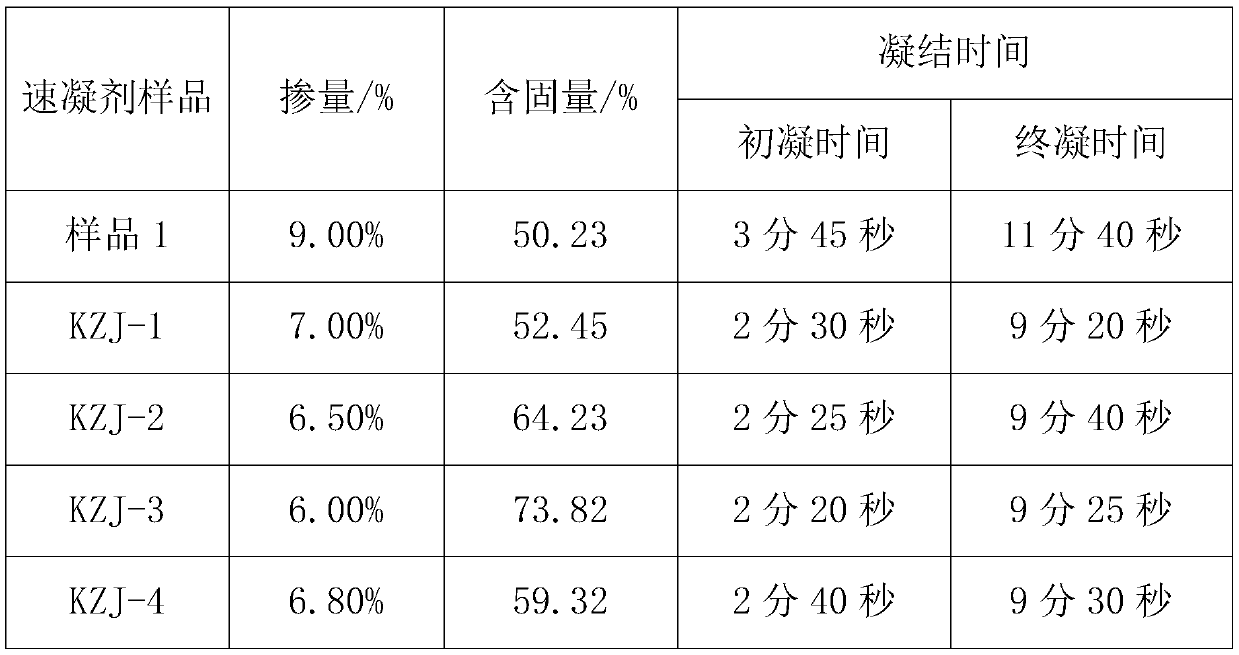

Examples

Embodiment 1

[0022] (1) Preparation of complexing enhancer: 100.00g ethylenediaminetetraacetic acid is added in the reactor, the stirring device is opened, and 24.00g monoethanolamine and 1.20g p-toluenesulfonic acid are added in one go to react at a temperature of 80 At ℃, react for 3 hours to obtain the complexation enhancer;

[0023] (2) Preparation of stabilizer: Add 100.00g of bottom water to the reactor, turn on the stirring device, control the temperature of the reactor to 40°C, and then add 2-fluorocinnamic acid and 3-fluorocinnamic acid dropwise to the reactor respectively. Mixed solution (wherein 2-fluorocinnamic acid is 18.00g, 3-fluorocinnamic acid is 2.00g, water is 20.00g), acrylic acid aqueous solution (wherein acrylic acid is 46.00g, water is 20.00g), ammonium persulfate aqueous solution (wherein Ammonium sulfate is 1.00g, water is 10.00g) and thioglycolic acid aqueous solution (wherein thioglycolic acid is 0.60g, and water is 10.00g), and the dropping time is 2.0h. After t...

Embodiment 2

[0026] (1) Preparation of complexation enhancer: 100.00g of ethylenediaminetetraacetic acid is added to the reaction kettle, the stirring device is turned on, and 36.00g of diethanolamine and 2.00g of concentrated sulfuric acid are added at one time to react at a temperature of 90°C , reacted for 3h to obtain the complexation enhancer;

[0027] (2) Preparation of stabilizer: Add 100.00g of bottom water to the reactor, turn on the stirring device, control the temperature of the reactor to 30°C, and then add 2-fluorocinnamic acid and 4-fluorocinnamic acid dropwise to the reactor respectively. Mixed solution (wherein 2-fluorocinnamic acid is 10.00g, 4-fluorocinnamic acid is 10.00g, water is 20.00g), acrylic acid aqueous solution (wherein acrylic acid is 37.00g, water is 20.00g), ammonium persulfate aqueous solution (wherein Ammonium sulfate is 1.70g, water is 10.00g) and mercaptopropionic acid aqueous solution (ammonium mercaptopropionic acid is 1.00g, water is 10.00g), and the t...

Embodiment 3

[0030] (1) Preparation of complexation enhancer: 100.00g of ethylenediaminetetraacetic acid was added to the reaction kettle, the stirring device was turned on, and 39.00g of triethanolamine and 2.70g of concentrated sulfuric acid were added at one time to react at a temperature of 70°C , reacted for 4h to obtain the complexation enhancer;

[0031] (2) Preparation of stabilizer: Add 100.00g of bottom water to the reactor, turn on the stirring device, control the temperature of the reactor to 50°C, and then add 3-fluorocinnamic acid and 2-(trifluoroform base) cinnamic acid mixed solution (wherein 3-fluorocinnamic acid is 16.00g, 2-(trifluoromethyl)cinnamic acid is 4.00g, water is 20.00g), acrylic acid aqueous solution (wherein acrylic acid is 50.00g, water is 20.00g g), ammonium persulfate aqueous solution (wherein ammonium persulfate is 2.00g, water is 10.00g) and mercaptoethanol aqueous solution (wherein mercaptoethanol is 1.40g, water is 10.00g), the dropping time is 2.0h, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com