Preparation method of flame-resistant polypropylene board

A polypropylene board and raw material technology, applied in the field of polypropylene board, can solve the problems of poor flame retardancy, toughness, poor low temperature and aging resistance, large molding shrinkage, etc., to achieve improved flame retardancy and heat resistance, good Heat resistance and flame retardant performance, the effect of improving the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of a flame-retardant polypropylene plate, comprising the steps of:

[0033] Step 1, adding the organosilicon raw material into toluene, stirring at room temperature until completely dissolved, to obtain a toluene solution; the organosilicon raw material is methyltrichlorosilane;

[0034] Step 2, adding distilled water into a constant pressure dropping funnel, slowly adding it dropwise into the toluene solution at a constant temperature, stirring evenly, and standing for 2 hours to obtain an acidic hydrolyzate;

[0035] Step 3, passing ammonia gas into the acidic hydrolyzate until the hydrolyzate is neutral, adding an aluminum silicate catalyst, copolymerized polypropylene powder and homopolypropylene powder and stirring evenly to form a suspension;

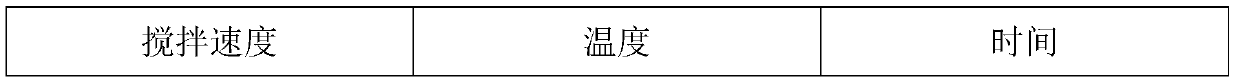

[0036] In step 4, the suspension is stirred for a gradient heating reaction, pressurized and cooled to form a flame-retardant polypropylene plate.

[0037] The concentration of the organosilicon raw mate...

Embodiment 2

[0045] A preparation method of a flame-retardant polypropylene plate, comprising the steps of:

[0046] Step 1, adding the organosilicon raw material into toluene, stirring at room temperature until completely dissolved to obtain a toluene solution; the organosilicon raw material is dimethyldichlorosilane;

[0047] Step 2, adding distilled water into a constant pressure dropping funnel, slowly adding it dropwise into the toluene solution at a constant temperature, stirring evenly, and standing for 5 hours to obtain an acidic hydrolyzate;

[0048] Step 3, passing ammonia gas into the acidic hydrolyzate until the hydrolyzate is neutral, adding an aluminum silicate catalyst, copolymerized polypropylene powder and homopolypropylene powder and stirring evenly to form a suspension;

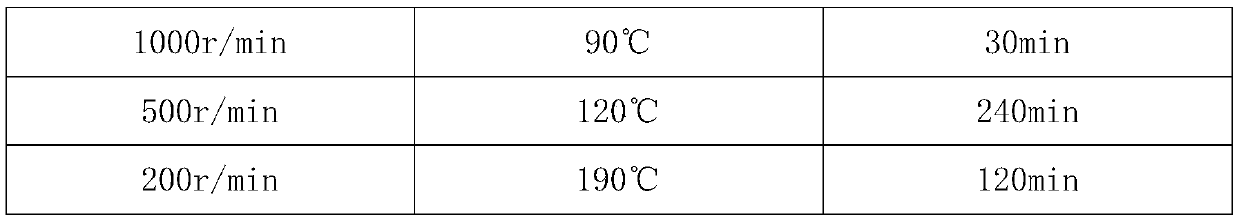

[0049] In step 4, the suspension is stirred for a gradient heating reaction, pressurized and cooled to form a flame-retardant polypropylene plate.

[0050] The concentration of the organosilicon raw ma...

Embodiment 3

[0058] A preparation method of a flame-retardant polypropylene plate, comprising the steps of:

[0059] Step 1, adding the organosilicon raw material into toluene, stirring at room temperature until completely dissolved, to obtain a toluene solution; the organosilicon raw material is phenyltrichlorosilane;

[0060] Step 2, adding distilled water into a constant pressure dropping funnel, slowly adding it dropwise into the toluene solution at a constant temperature, stirring evenly, and standing for 3 hours to obtain an acidic hydrolyzate;

[0061] Step 3, passing ammonia gas into the acidic hydrolyzate until the hydrolyzate is neutral, adding an aluminum silicate catalyst, copolymerized polypropylene powder and homopolypropylene powder and stirring evenly to form a suspension;

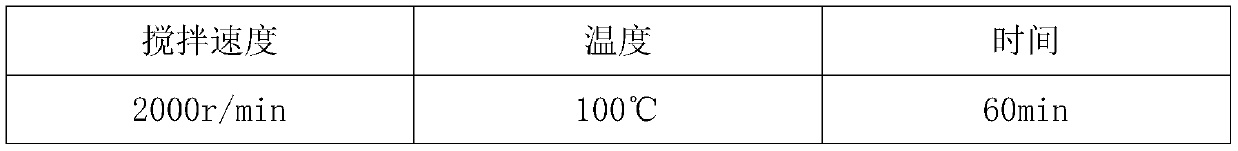

[0062] In step 4, the suspension is stirred for a gradient heating reaction, pressurized and cooled to form a flame-retardant polypropylene plate.

[0063] The concentration of the organosilicon raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com