Water-based color-changing coating and coated product thereof

A color-changing paint, water-based technology, used in antifouling/underwater paints, heat-sensitive paints, polyurea/polyurethane paints, etc. problems, to achieve the effect of enhancing curing efficiency, large-scale industrial production benefits, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment relates to a photosensitive thermochromic coating product, which includes a photosensitive thermochromic layer, and the color changing layer is formed by curing a water-based color changing paint.

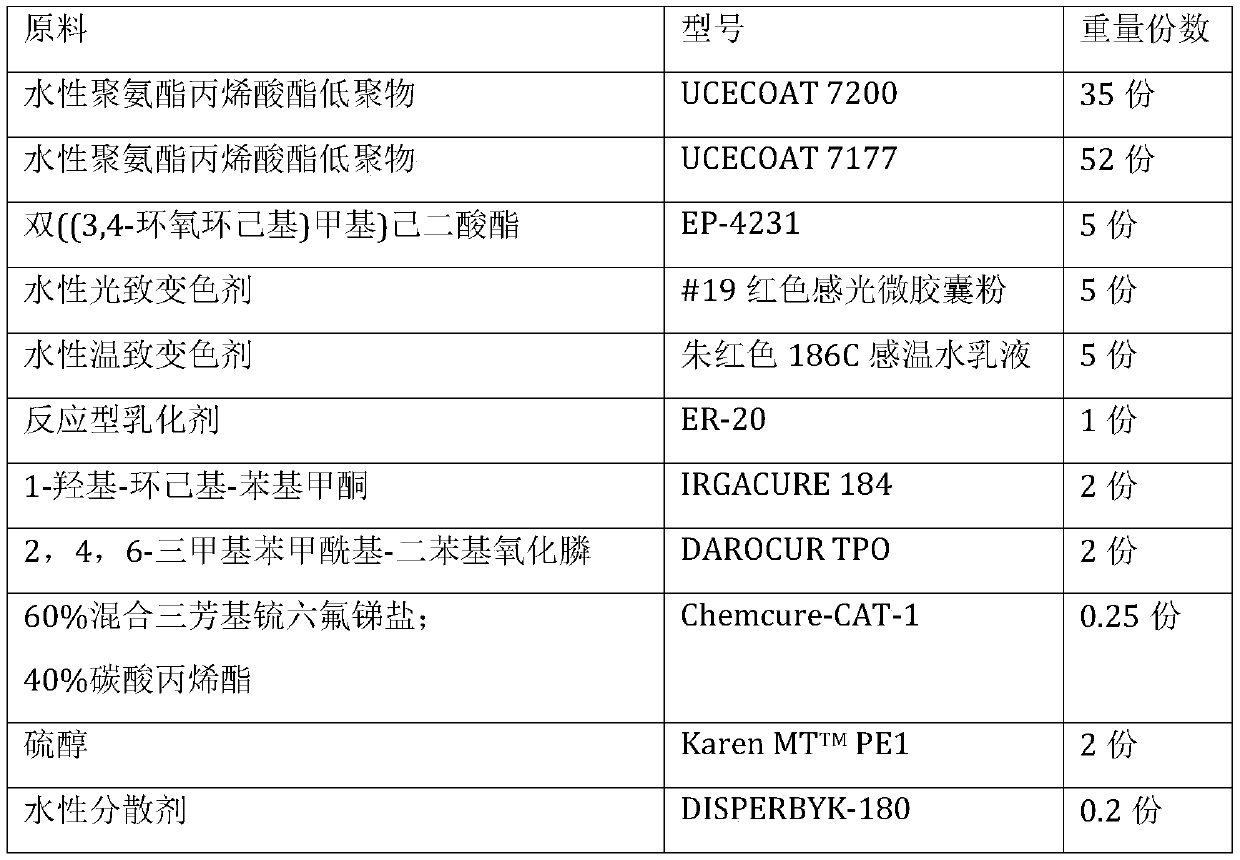

[0046] The composition of the water-based color-changing paint is shown in Table 1.

[0047] Table 1 Water-based color-changing paint composition list

[0048]

[0049] The preparation process is as follows:

[0050] Add 35 parts of water-based polyurethane acrylate oligomer UCECOAT 7200 (Allnex) and 52 parts of water-based polyurethane acrylate oligomer UCECOAT 7177 (Allnex) into a mixing tank with a condenser, and form an emulsion system after stirring ; Under the condition of stirring at a constant speed, add 1 part of reactive emulsifier ER-20 (ADEKA company) into the above-mentioned emulsion system to make it uniformly dispersed, the stirring speed is 800r / min, and stir for 0.5h;

[0051] Add 0.2 parts of water-based dispersant DISPERBYK-180 (BYK co...

Embodiment 2

[0055] This embodiment relates to a photosensitive thermochromic coating product, which includes a photosensitive thermochromic layer, and the color changing layer is formed by curing a water-based color changing paint.

[0056] The composition of the water-based color-changing paint is shown in Table 2.

[0057] Table 2 Water-based color-changing paint composition list

[0058]

[0059]

[0060] The preparation process is as follows:

[0061] 40 parts of water-based polyurethane acrylate oligomer UCECOAT 7210 (Allnex), 45 parts of water-based polyurethane acrylate oligomer UCECOAT 7689 (Allnex) and 9 parts of fluorine compound aqueous emulsion HEXAFOR T-70 (Guangzhou Yangsong Trading Co., Ltd.), add it to the mixing tank with a condenser, and form an emulsion system after stirring; under the condition of constant stirring, add 1.5 parts of reactive emulsifier SR-20 (ADEKA company) to the above emulsion system to make it uniform Dispersion, stirring speed 800r / min, sti...

Embodiment 3

[0067] This embodiment relates to a photosensitive thermochromic coating product, which includes a photosensitive thermochromic layer, and the color changing layer is formed by curing a water-based color changing paint.

[0068] The composition of the water-based color-changing paint is shown in Table 3.

[0069] Table 3 Water-based color-changing paint composition list

[0070]

[0071]

[0072] The preparation process is as follows:

[0073] Add 50 parts of water-based polyurethane acrylate oligomer UCECOAT 7699 (Allnex) and 35 parts of water-based polyurethane acrylate oligomer UCECOAT 6558 (Allnex) into a mixing tank with a condenser, and form an emulsion system after stirring ; Under the condition of stirring at a constant speed, add 0.5 part of reactive emulsifier NE-10 (ADEKA company) and 0.5 part of reactive emulsifier SE-10N (ADEKA company) into the above-mentioned emulsion system to make it uniformly dispersed, stirring speed 800r / min, stirring for 0.5h;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com