Thermo-responsive upconversion luminescent material and preparation method thereof

A luminescent material, dodecacalcium technology, applied in luminescent materials, chemical instruments and methods, etc., to achieve the effect of improving up-conversion luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

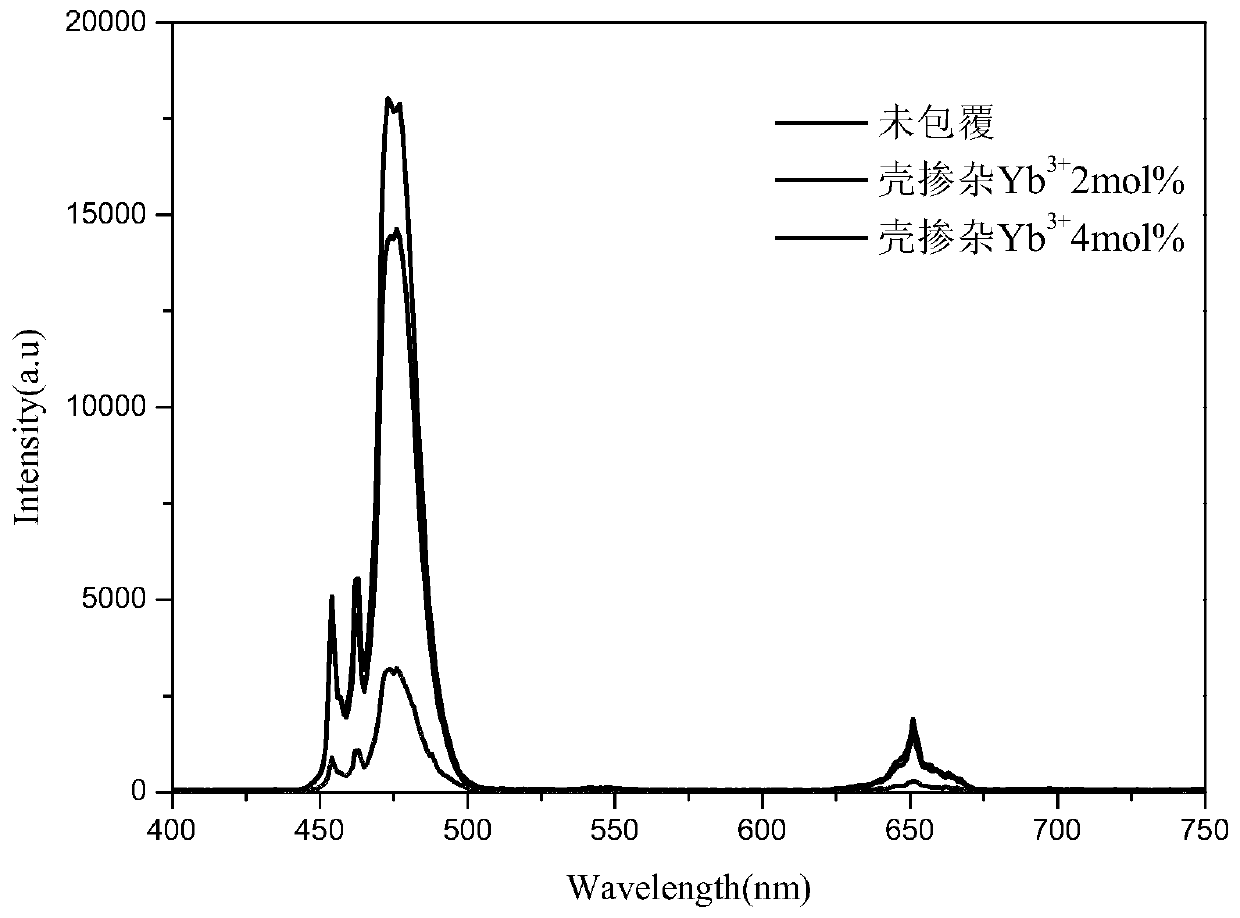

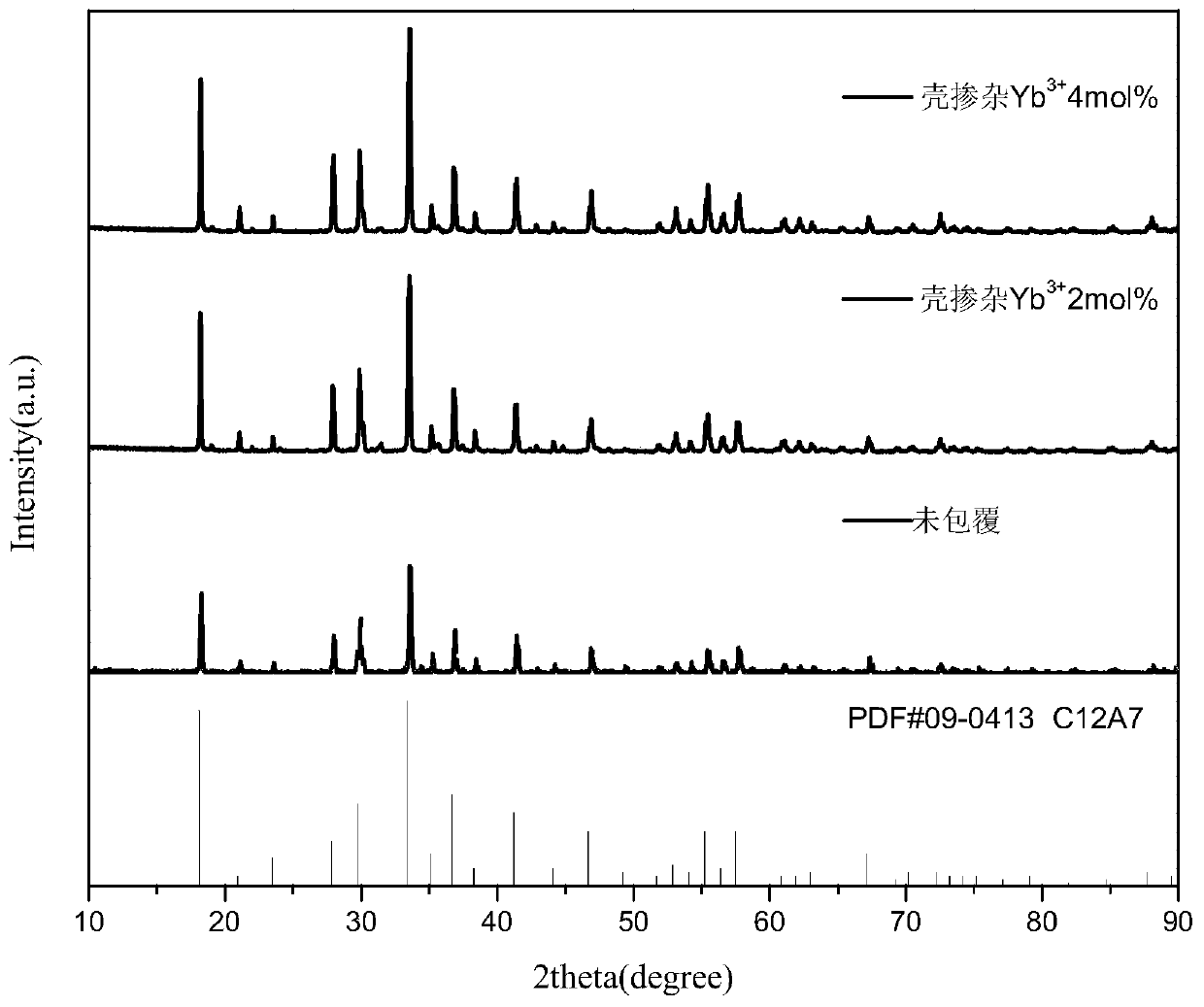

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Preparation of core (C12A7:Yb3.0 / Tm0.2). Weigh 1.8782g of calcium hydroxide, 2.3068g of aluminum hydroxide, 0.0505g of thulium nitrate pentahydrate and 0.7645g of ytterbium nitrate pentahydrate, add 80ml of alcohol to carry out ball milling, then move the mixed solution after ball milling to the reaction kettle, at 150°C Keep warm for 6 hours, cool to room temperature, filter, dry at 90°C for 12 hours, and then calcine in a muffle furnace at 1200°C, cool to room temperature, and grind to obtain a powder sample C12A7:Yb3 .0 / Tm0.2.

[0027] Step 2: Weigh 0.0449g of calcium hydroxide, 0.0551g of aluminum hydroxide, 0g of ytterbium nitrate pentahydrate (0mol%), add 20ml of absolute ethanol ball mill, and then weigh 0.1g of C12A7:Yb3.0 prepared in step 1 / Tm0.2 into a 100ml beaker, add 60ml of absolute ethanol and ultrasonically disperse for 30min. ;

[0028] Step 3: transfer the mixed solution after ball milling and C12A7:Yb3.0 / Tm0.2 after ultrasonic dispersion t...

Embodiment 2

[0033] The difference between this embodiment and Example 1 is that the calcium hydroxide, aluminum hydroxide and ytterbium nitrate pentahydrate in step 2 can be 12:14 according to the molar ratio of calcium and aluminum atoms, and the doping concentration of ytterbium nitrate pentahydrate is 0 ~4mol% for free mix. Others are the same as in Example 1.

Embodiment 3

[0035] The difference between this embodiment and Example 1 is that the total mass of calcium hydroxide, aluminum hydroxide, and ytterbium nitrate pentahydrate in step 2 ranges from 0.1g to 0.18 under the condition that the molar ratio of calcium and aluminum atoms is 12:14 g changes. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com