Wireless charging high-frequency power supply

A technology of wireless charging and high-frequency power supply, applied in charging stations, battery circuit devices, electric vehicle charging technology, etc. Interference ability, strong anti-interference ability, the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The purpose of the present invention is to design a wireless charging high-frequency power supply to solve the problem of inconvenient control of the output voltage and output AC frequency of the power supply during wireless charging of electric vehicles. The function of alarming during abnormal working conditions, for the convenience of understanding, the specific implementation will be further described below in conjunction with the accompanying drawings.

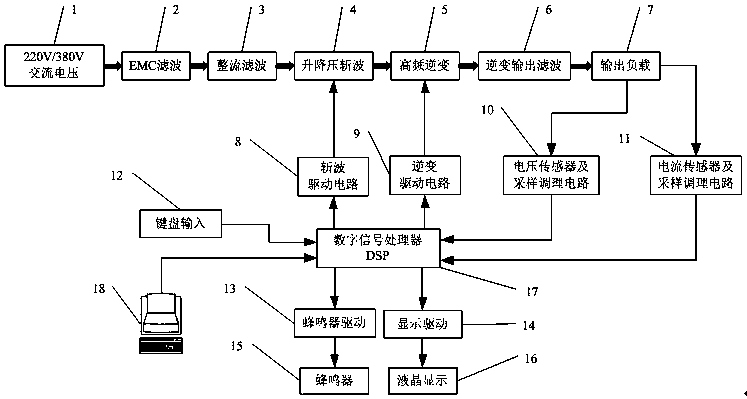

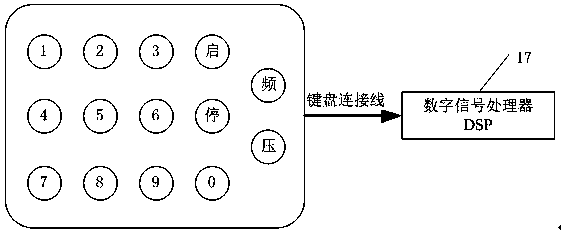

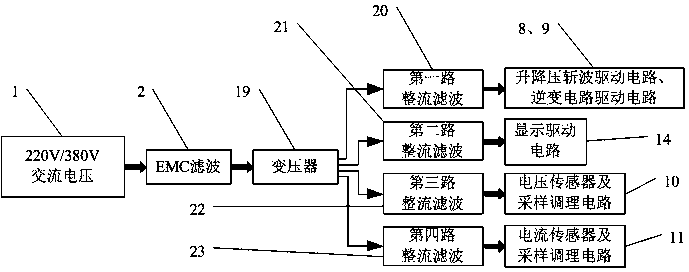

[0030] as attached figure 1 , attached figure 2 And attached image 3 A structural schematic diagram of the wireless charging high-frequency power supply, which includes a 220V / 380V AC voltage 1, an EMC filter 2, a rectification filter circuit 3, a buck-boost chopper circuit 4, a high-frequency inverter circuit 5, and an inverter output filter Circuit 6, output load 7, chopping drive circuit 8, inverter drive circuit 9, voltage sampling and conditioning circuit 10, current sampling and conditioning circuit 11, ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com