Lubrication water device for open type water lubrication tail bearing and operation method of device

A technology for lubricating water and stern bearings, applied in the field of ships, can solve the problems of environmental protection lubricating oil lubricating stern bearings reliability, oil lubricating stern bearings polluting navigation waters, and reducing reliability and life, achieving multi-functional integration. , a wide range of flow and pressure regulation, the effect of improving reliability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

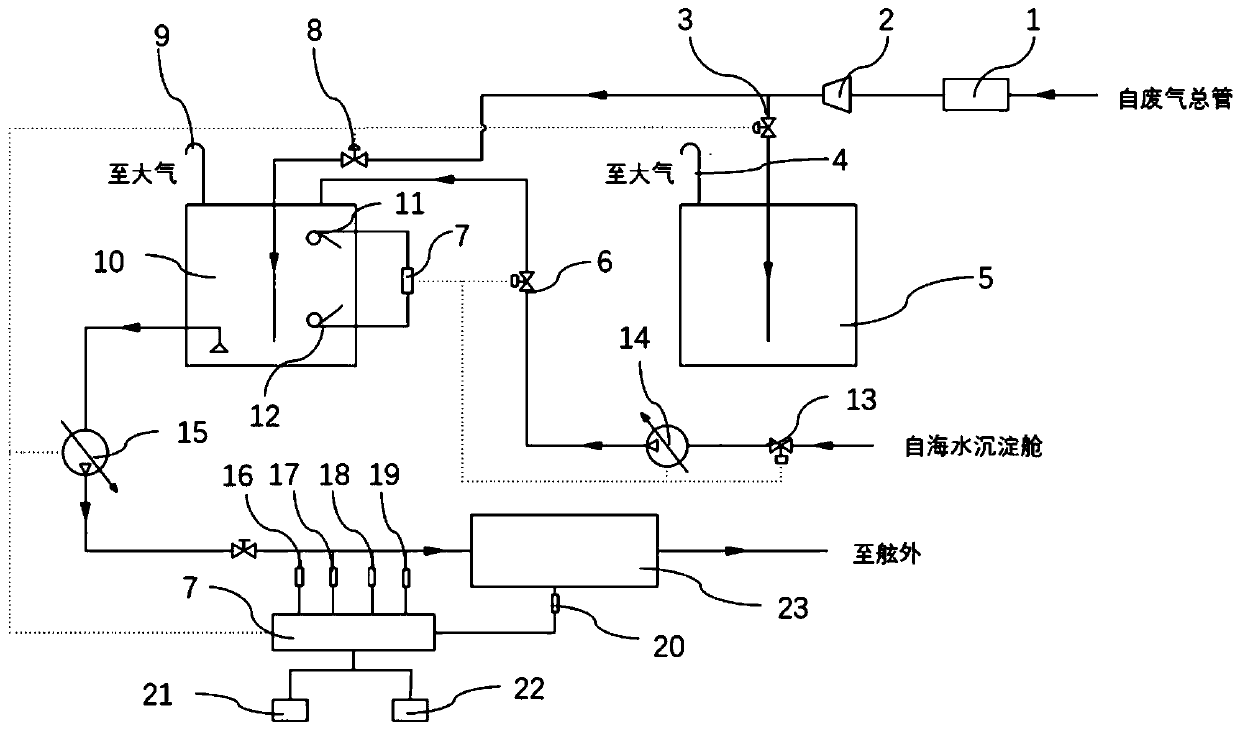

[0027] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] The invention is a lubricating water device suitable for lubricating the stern bearing with open water, which is installed on ships navigating in cold waters, and can supply water to meet the requirements of lubricating the stern bearing while removing sulfur oxides in exhaust gas. Such as figure 1As shown, the device includes an oxidizer 1, a compressor 2, a seawater desulfurization chamber 5, a seawater supply pump 14, a lubricating seawater chamber 10, a lubricating seawater supply pump 15, a lubricating water inlet temperature sensor 16, a pressure sensor 17, an ice crystal granularity Sensor 18, pH value sensor 19, tail shaft tail pipe device 23 temperature sensor 20, tail shaft tail pipe device 23, single chip microcomputer 7 (ie controller), display 21, computer 22. The inlet of the oxidizer 1 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com