Aqueous polyurethane resin for super black and misty surface processing agent and preparation method thereof

A water-based polyurethane and surface treatment technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of inability to achieve non-toxic and non-polluting, and the synthetic leather is difficult to have a special black and special fog effect. Good alcohol resistance and the effect of improving water and alcohol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

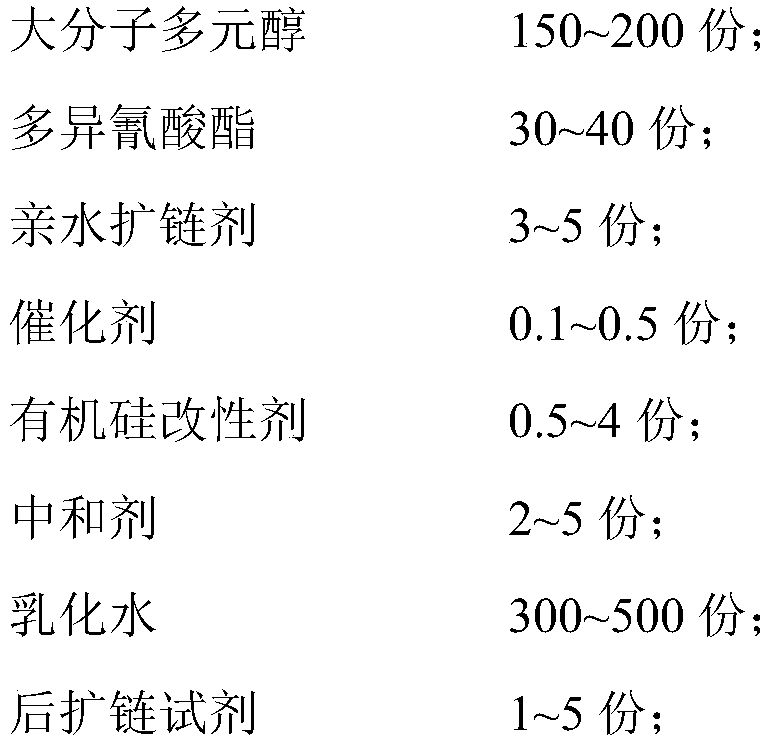

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the water-based polyurethane resin for the special black surface treatment agent also includes the step (2) of adjusting the temperature to 30-40° C., adding the organic silicon modifier, and mixing and reacting for 0.5-1 hour.

[0031]In step (2), after the system has reacted for 6 to 8 hours, under the condition of 30 to 40 ° C, an organosilicon modifier is added to the system. The low surface energy of the silane coupling agent can endow the material with good hydrolysis resistance. At the same time, the silane coupling agent forms a cross-linked structure after hydrolysis, which can endow the surface treatment agent with good scratch resistance.

[0032] The preparation method of the water-based polyurethane resin for Tehei special fog surface treatment agent also includes step (3) adjusting the temperature to 0-25°C, adding the neutralizing agent, reacting for 1-5 minutes, adding emulsified water under high-speed stirring, so that After be...

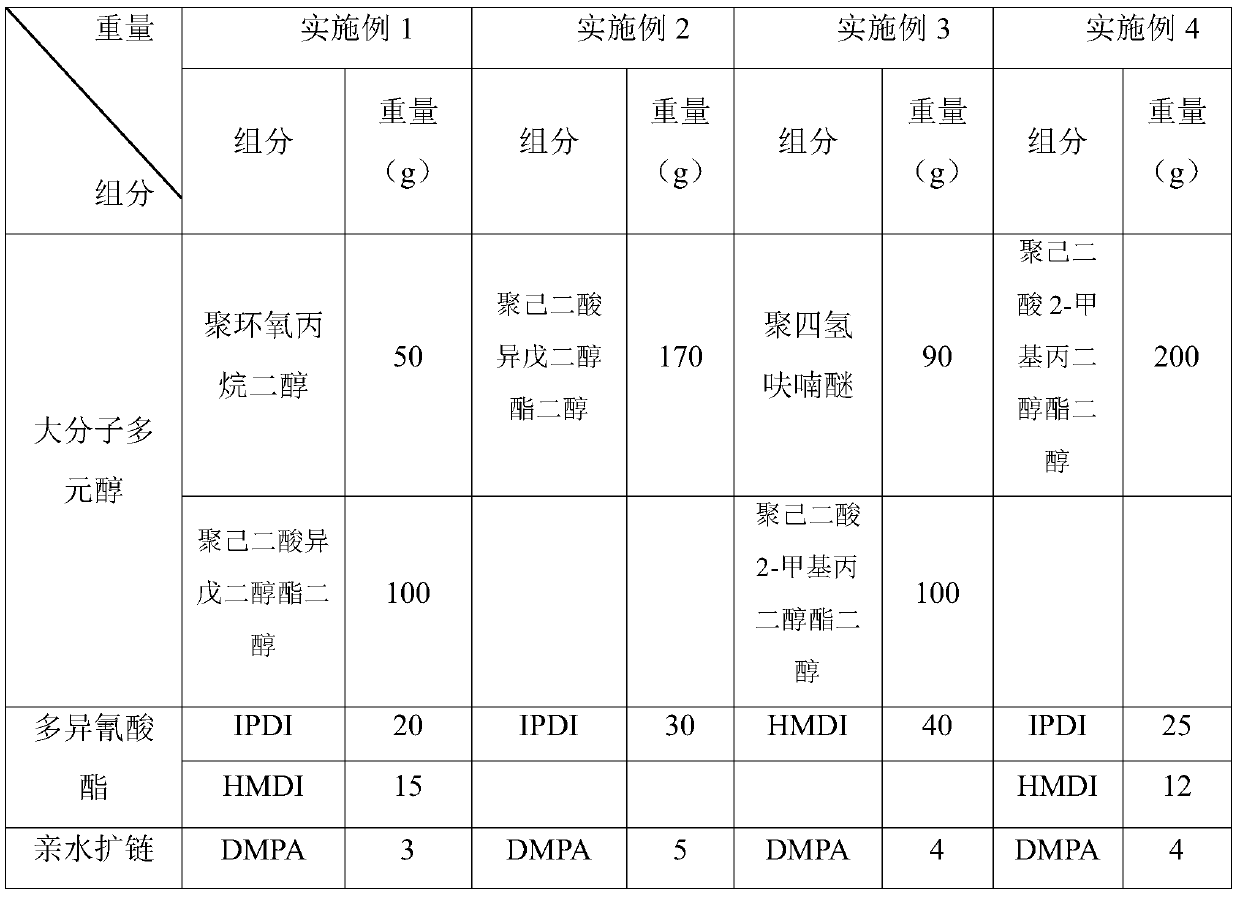

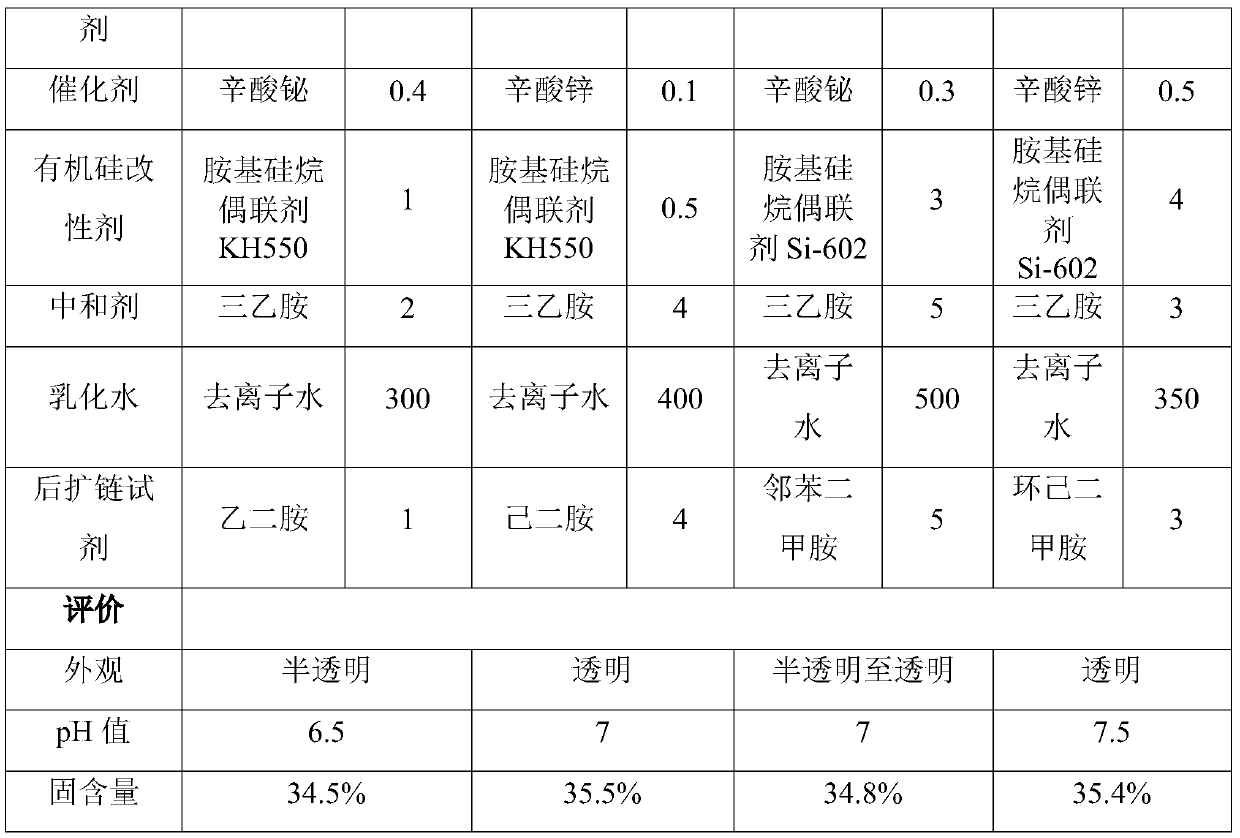

Embodiment 1

[0037] 1. Preparation of waterborne polyurethane resin

[0038] 1) 50g of polypropylene oxide diol, 100g of polyisoprene adipate diol, 35g of IPDI, 15g of HMDI, 3g of DMPA, 0.4g of bismuth octoate and 5g of diluent acetone were mixed and reacted at 75°C for 7h;

[0039] 2) Adjust the temperature to 50°C, add 120g of diluent acetone and mix; add 1g of aminosilane coupling agent KH550, adjust the temperature to the required emulsification temperature of 10°C, add 2g of triethylamine for neutralization, and the neutralization time is 2min Then add 300g of emulsified water under high-speed stirring to make it dispersed into an emulsion state, then add 1g of ethylenediamine to react, and the reaction time is 1h;

[0040] 3) Distill under reduced pressure at 30°C and vacuum at -0.07MPa. After stirring for 2 hours, the test result shows that there is no acetone smell and odor, and the solid content of the test is up to the standard, that is, the diluent acetone is removed to obtain w...

Embodiment 2

[0042] 1. Preparation of waterborne polyurethane resin

[0043] 1) 170g of polyisoamyl adipate diol, 40g of HMDI, 5g of DMPA, 0.1g of zinc caprylate and 8g of diluent acetone were mixed and reacted at 75°C for 7h;

[0044] 2) Adjust the temperature to 10°C, add 0.5g of aminosilane coupling agent KH550, and mix for 0.5h;

[0045] 3) Adjust the temperature to 55°C, add 140g of diluent acetone and mix; adjust the temperature to the required emulsification temperature of 15°C, add 4g of triethylamine for neutralization, and add 400g of emulsified water under high-speed stirring after the neutralization time of 1min, so that After being dispersed into an emulsion state, 4g of hexamethylenediamine was added for reaction, and the reaction time was 0.6h;

[0046] 5) Distill under reduced pressure at 50°C and vacuum at -0.08MPa. After stirring for 3 hours, the test result shows that there is no acetone smell and odor, and the solid content of the test is up to standard, that is, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com