Comprehensive circulation utilization-regeneration method of various waste and old epoxy paints

A technology of epoxy paint and waste, which is applied in the direction of recycling technology, epoxy resin paint, coating, etc., can solve problems such as environmental pollution, resource waste, and inconsistency with the theme of the times, achieve high solid content, save resources, The effect of dense coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

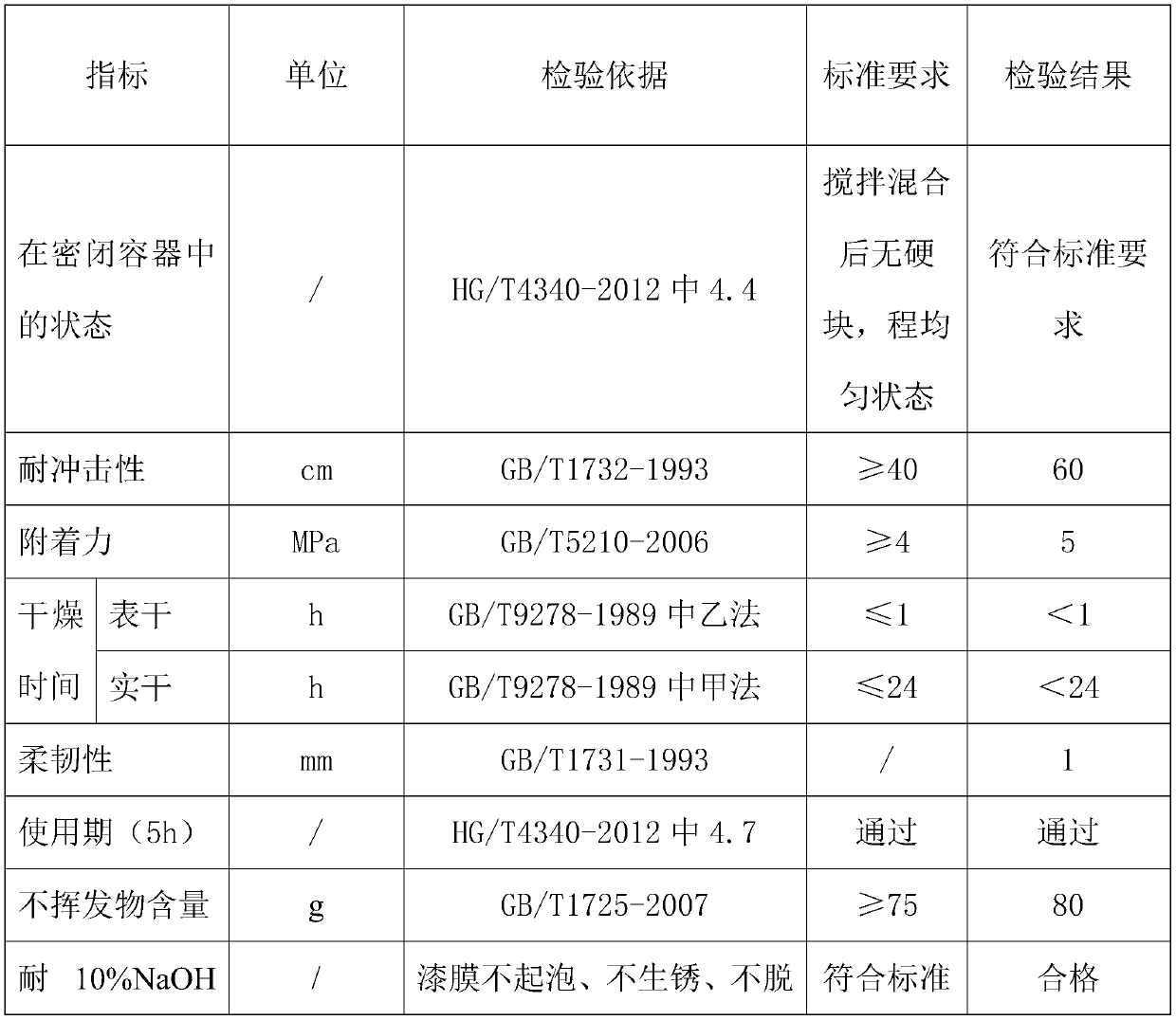

Embodiment 1

[0026] This embodiment provides a comprehensive recycling regeneration method for various types of waste epoxy paint, including the following steps:

[0027] 1: Firstly, sort the heavy-duty waste epoxy paints and other types after coating construction according to the base material components, put the sorted heavy-duty waste paints with epoxy components into airtight containers, and then put them into a sealed container. Add the mixed solvent of cyclohexanone, n-butanol and ethyl carbonate into a closed container and stir evenly, then soak for more than 4 hours to obtain waste paint A;

[0028] 2. Put the closed container containing waste paint A in step 1 into the agitator, start the agitator, disperse and stir at a speed of 300 rpm for more than 1 hour, and heat at the same time. When the temperature reaches 80 degrees, keep the temperature , the impurity filtered out by airtight automatic control fine filter screen equipment is the cured product and paint leather residue pr...

Embodiment 2

[0036] This embodiment provides a comprehensive recycling regeneration method for various types of waste epoxy paint, including the following steps:

[0037] One: First, sort the heavy-duty waste epoxy paints and other types of heavy-duty epoxy paints that have been painted in the factory and other categories according to the base material composition, and put the sorted epoxy-based heavy-duty waste paints into an airtight container, and then Add the mixed solvent of cyclohexanone, n-butanol and ethyl carbonate into an airtight container and stir evenly, then soak for more than 4 hours to obtain waste paint A;

[0038] 2. Put the closed container containing waste paint A in step 1 into the agitator, start the agitator, disperse and stir at a speed of 300 rpm for more than 1 hour, and heat at the same time. When the temperature reaches 80 degrees, keep the temperature , the impurity filtered out by airtight automatic control fine filter screen equipment is the cured product and...

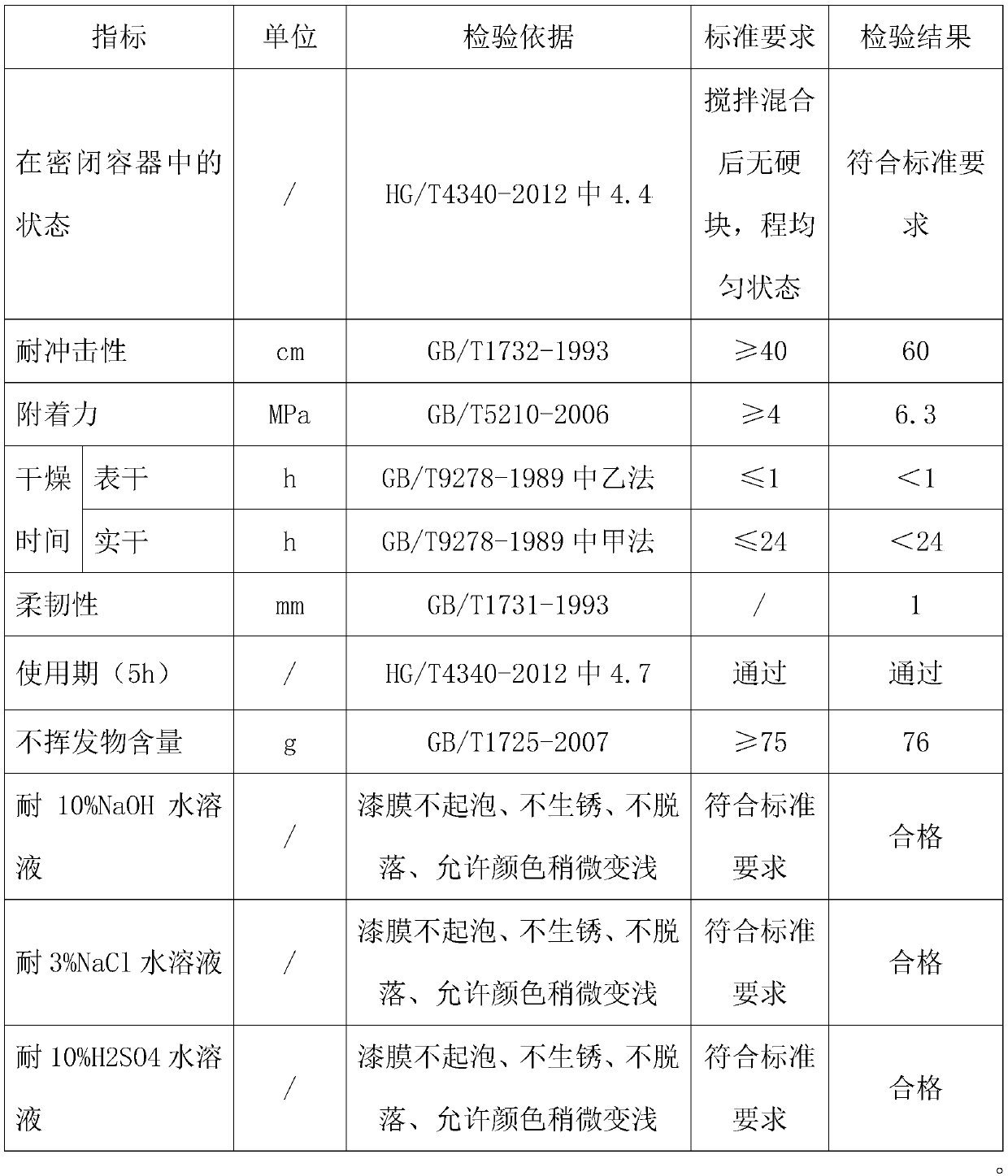

Embodiment 3

[0045] This embodiment provides a comprehensive recycling regeneration method for various types of waste epoxy paint, including the following steps:

[0046] One: First, sort the heavy-duty waste epoxy paints and other types of heavy-duty epoxy paints that have been painted in the factory and other categories according to the base material composition, and put the sorted epoxy-based heavy-duty waste paints into an airtight container, and then Add the mixed solvent of cyclohexanone, n-butanol and ethyl carbonate into an airtight container and stir evenly, then soak for more than 4 hours to obtain waste paint A;

[0047] 2. Put the closed container containing waste paint A in step 1 into the agitator, start the agitator, disperse and stir at a speed of 300 rpm for more than 1 hour, and heat at the same time. When the temperature reaches 80 degrees, keep the temperature , the impurity filtered out by airtight automatic control fine filter screen equipment is the cured product and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com