A kind of 3D structure composite hydrogen evolution electrode and preparation method thereof

A hydrogen evolution electrode and composite electrode technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., to achieve the effect of high specific surface area, simple operation process, and excellent electrocatalytic hydrogen evolution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

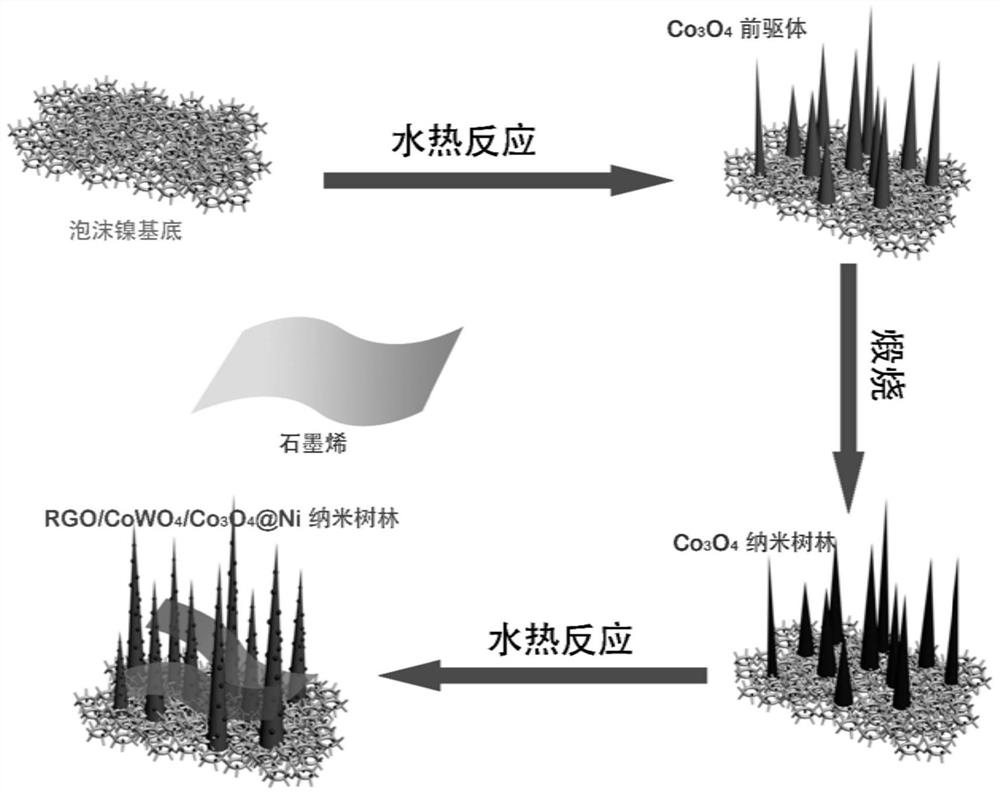

[0038] A method for preparing a composite hydrogen evolution electrode with a 3D structure, the specific steps are:

[0039] (1) Pretreatment of substrate

[0040]Before the hydrothermal reaction, immerse the foamed nickel substrate in a container filled with deionized water, and ultrasonically treat it for 5 minutes; then put the foamed nickel in 6M HCl solution for 30 seconds to remove oxides on the surface, and then use absolute ethanol, Wash with ionized water until neutral, and dry for later use;

[0041] (2) Preparation of graphene oxide dispersion

[0042] Prepare graphite oxide by the improved Hummers method, add 200mg graphite oxide to 100mL deionized water, and ultrasonically disperse with 300W ultrasonic power for 1h to obtain a tan graphene oxide dispersion with a concentration of 2mg mL -1 .

[0043] (3)Co 3 o 4 Preparation of @Ni Nano Forest

[0044] Dissolve 2.5mmol of cobalt nitrate and 12.5mmol of urea in 50mL of deionized water and stir for 30min until ...

Embodiment 2

[0055] (1) Pretreatment of substrate

[0056] Before the hydrothermal reaction, immerse the foamed nickel substrate in a container filled with deionized water, and ultrasonically treat it for 5 minutes; then put the foamed nickel in 6M HCl solution for 30 seconds to remove oxides on the surface, and then use absolute ethanol, Wash with ionized water until neutral, and dry for later use;

[0057] (2) Preparation of graphene oxide dispersion

[0058] Prepare graphite oxide by the improved Hummers method, add 150mg graphite oxide to 100mL deionized water, and ultrasonically disperse with 300W ultrasonic power for 1h to obtain a tan graphene oxide dispersion with a concentration of 1.5mg mL -1 .

[0059] (3)Co 3 o 4 Preparation of @Ni Nano Forest

[0060] Dissolve 2.5mmol of cobalt nitrate and 12.5mmol of urea in 50mL of deionized water and stir for 30min until completely dissolved, then pour it into a hydrothermal kettle, then place the nickel foam (6cm×2cm× 0.1cm) into the...

Embodiment 3

[0067] (1) Pretreatment of substrate

[0068] Before the hydrothermal reaction, immerse the foamed nickel substrate in a container filled with deionized water, and ultrasonically treat it for 5 minutes; then put the foamed nickel in 6M HCl solution for 30 seconds to remove oxides on the surface, and then use absolute ethanol, Wash with ionized water until neutral, and dry for later use;

[0069] (2) Preparation of graphene oxide dispersion

[0070] Prepare graphite oxide by the improved Hummers method, add 100mg graphite oxide to 100mL deionized water, ultrasonically disperse with 300W ultrasonic power for 1h, and obtain a tan graphene oxide dispersion with a concentration of 1.0mg mL -1 .

[0071] (3)Co 3 o 4 Preparation of @Ni Nano Forest

[0072] Dissolve 2.5mmol of cobalt nitrate and 12.5mmol of urea in 50mL of deionized water and stir for 30min until completely dissolved, then pour it into a hydrothermal kettle, then place the nickel foam (6cm×2cm× 0.1cm) into the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com