A kind of environment-friendly interlining and its production method

A production method and interlining technology, which are applied in the manufacture of rayon, single-component polyester rayon, textiles and papermaking, etc., can solve the problems of unfavorable long-term wear by users, affecting the wearer's health, and affecting the breathability of hats, etc. Achieve good bactericidal effect, good perspiration, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

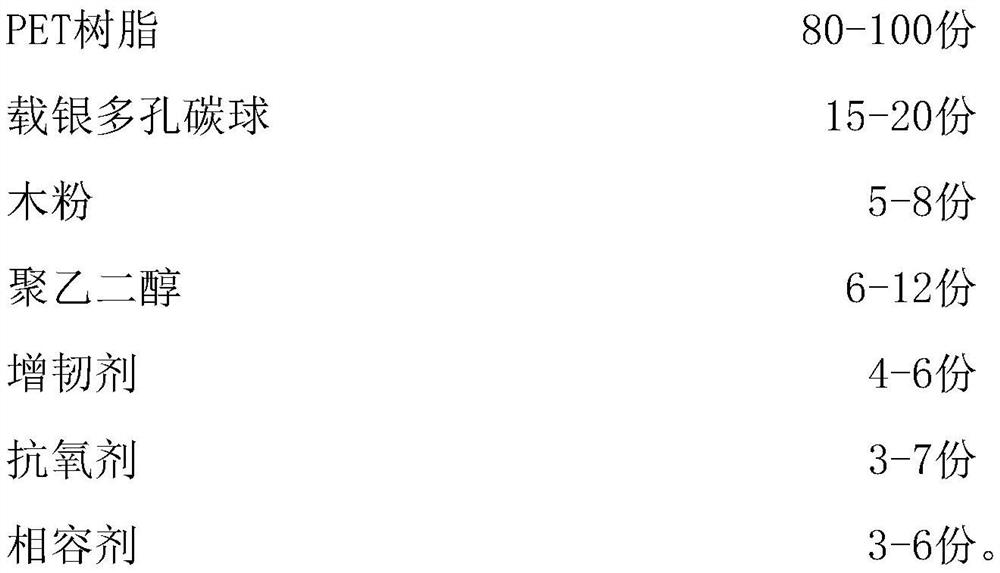

[0035] An environmental protection interlining, the base cloth of the environmental protection interlining is woven with antibacterial modified fiber as raw material, and the antibacterial modified fiber includes the following raw materials in parts by weight:

[0036]

[0037] The preparation method of described silver-loaded porous carbon spheres comprises the steps:

[0038] (1) Preparation of porous carbon spheres: take 55 parts by weight of starch aqueous solution with a mass percentage concentration of 45%, heat up to 175° C. and heat for 11 hours, then cool to room temperature to obtain a suspension; after centrifuging and separating the suspension, The product was washed three times with deionized water, dried at 55°C for 5.5 hours, and finally annealed at 900°C for 17.5 minutes to prepare porous carbon spheres;

[0039] (2) Pretreatment of the porous carbon spheres: the porous carbon spheres prepared in step (1) are ultrasonically dispersed in 0.75% tin protochlori...

Embodiment 2

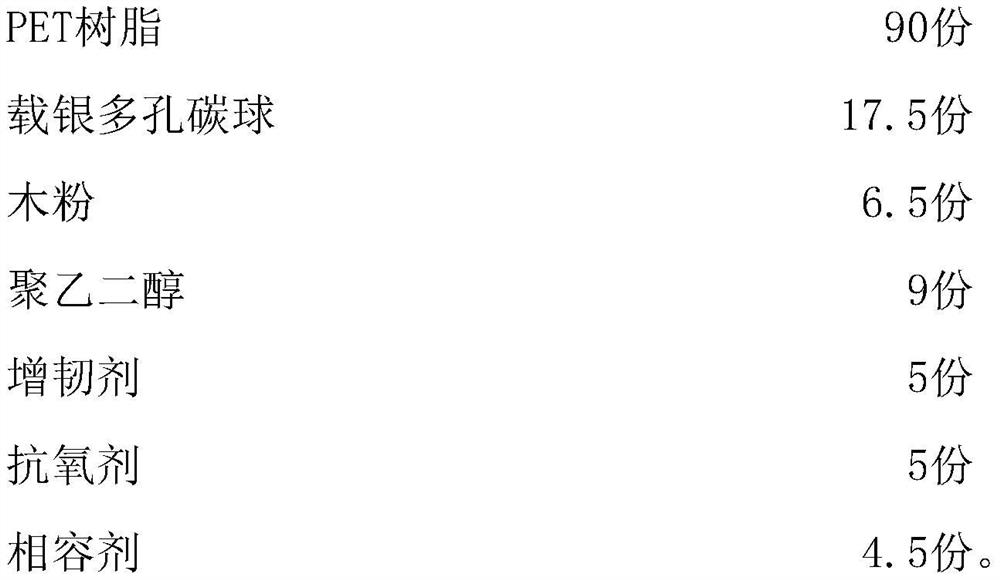

[0049] An environmental protection interlining, the base cloth of the environmental protection interlining is woven with antibacterial modified fiber as raw material, and the antibacterial modified fiber includes the following raw materials in parts by weight:

[0050]

[0051] The preparation method of described silver-loaded porous carbon spheres comprises the steps:

[0052] (1) Preparation of porous carbon spheres: take 50 parts by weight of starch aqueous solution with a mass percentage concentration of 40%, heat up to 150°C and heat for 10h, then cool to room temperature to obtain a suspension; after centrifuging and separating the suspension, The product was washed three times with deionized water, dried at 50°C for 5 hours, and finally annealed at 800°C for 15 minutes to prepare porous carbon spheres;

[0053] (2) Pretreatment of the porous carbon spheres: the porous carbon spheres prepared in step (1) are ultrasonically dispersed in 0.5% tin protochloride aqueous s...

Embodiment 3

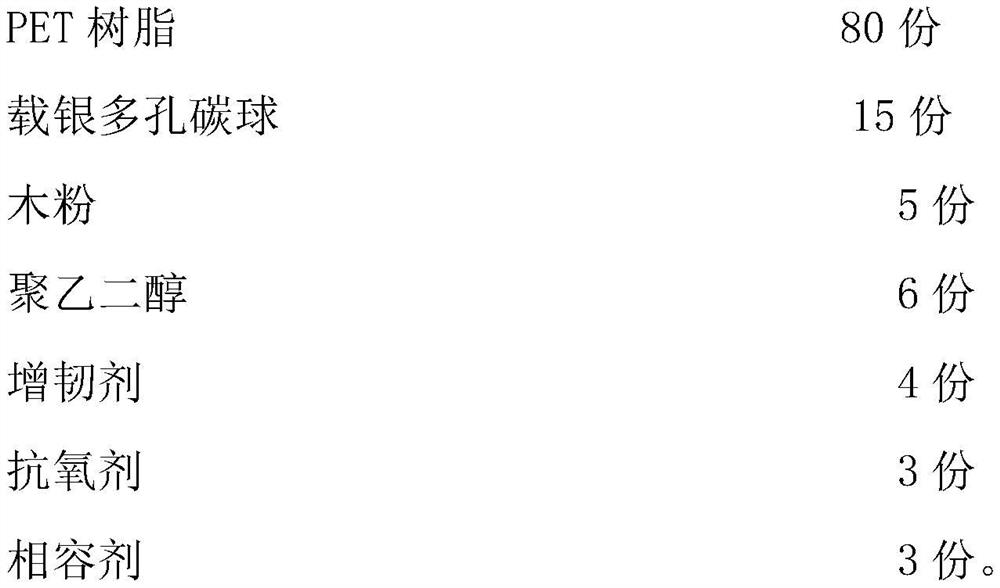

[0063] An environmental protection interlining, the base cloth of the environmental protection interlining is woven with antibacterial modified fiber as raw material, and the antibacterial modified fiber includes the following raw materials in parts by weight:

[0064]

[0065] The preparation method of described silver-loaded porous carbon spheres comprises the steps:

[0066] (1) Preparation of porous carbon spheres: take 60 parts by weight of starch aqueous solution with a concentration of 50% by mass, heat up to 200° C. and heat for 12 hours, then cool to room temperature to obtain a suspension; after centrifuging and separating the suspension, The product was washed three times with deionized water, dried at 60°C for 6 hours, and finally annealed at 1000°C for 20 minutes to prepare porous carbon spheres;

[0067] (2) Pretreatment of the porous carbon spheres: the porous carbon spheres prepared in step (1) are ultrasonically dispersed in 1% tin protochloride aqueous sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com