A method and system for judging the degradation effect of organic additives in gel phase

A technology of organic additives and determination methods, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of lack of determination methods and systems for the degradation effect of organic additives, and achieve the effects of efficient determination process, broad application prospects and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Method for judging the degradation effect of organic additives (excluding polyhydroxy polymers) in the gel phase of embodiment 1

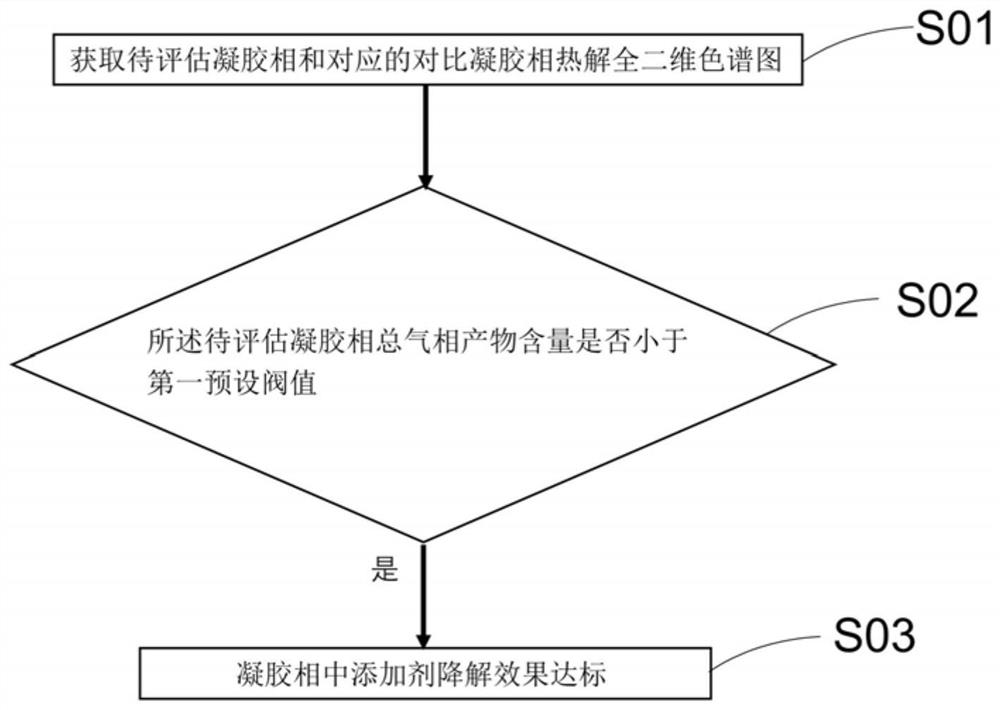

[0028] figure 1 It is a flow chart of the method for determining the degradation effect of organic additives (excluding polyhydroxy polymers) in the gel phase according to the present invention, and the specific process steps are as follows:

[0029] Step S01, obtaining the comprehensive two-dimensional chromatogram of the gel phase to be evaluated and the corresponding comparison gel phase pyrolysis.

[0030] Specifically, firstly, the temperature of the pyrolysis device is raised to above 600°C under an inert atmosphere. After constant temperature, the gel phase to be evaluated is quickly put into the pyrolysis device and the inlet is tightened to seal. Inert gas is used to carry the pyrolysis gas phase product from the pyrolysis device into the gas chromatograph, start the gas chromatograph and the solid-state thermal modulator in sequen...

Embodiment 2

[0036] Method for judging the degradation effect of organic additives (comprising polyhydroxy polymers) in the gel phase of embodiment 2

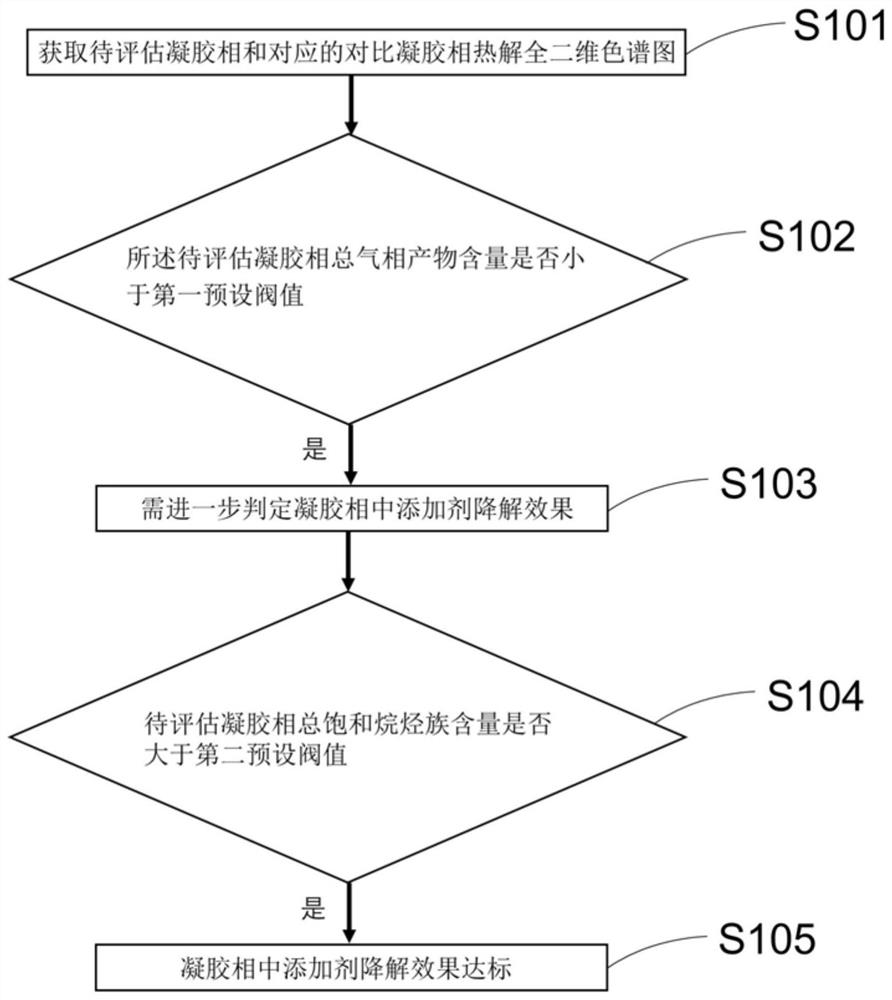

[0037] figure 2 It is a flow chart of the method for determining the degradation effect of organic additives (comprising polyhydroxy polymers) in the gel phase according to the present invention, and the specific process steps are as follows:

[0038] Step S101 , obtaining the pyrolysis comprehensive two-dimensional chromatogram of the gel phase to be evaluated and the corresponding comparative gel phase.

[0039] Specifically, firstly, the temperature of the pyrolysis device is raised to above 600°C under an inert atmosphere. After constant temperature, the gel phase to be evaluated is quickly put into the pyrolysis device and the inlet is tightened to seal. Inert gas is used to carry the pyrolysis gas phase product from the pyrolysis device into the gas chromatograph, start the gas chromatograph and the solid-state thermal modulator in ...

Embodiment 3

[0048] Example 3 Degradation Effect Determination System of Organic Additives in Gel Phase

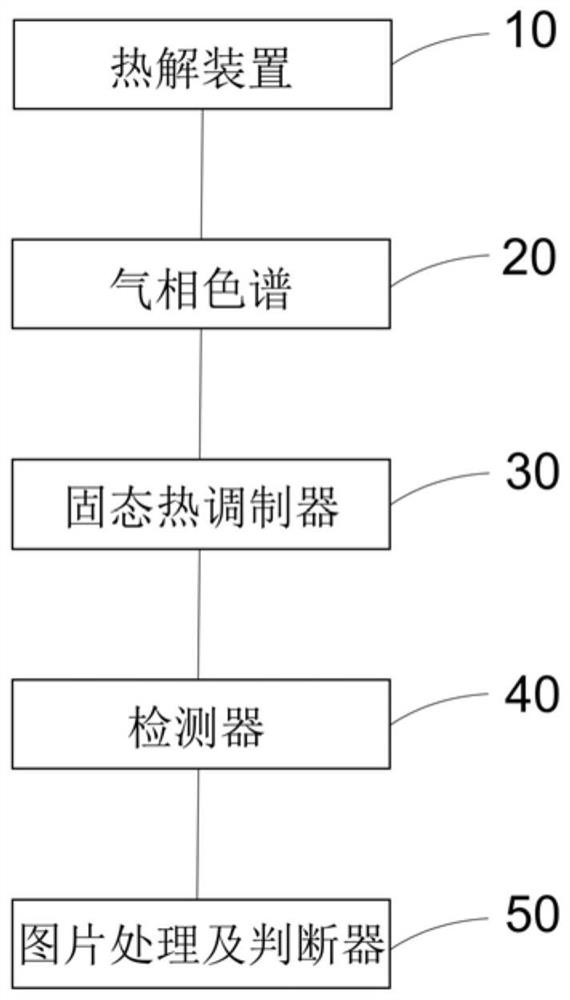

[0049] According to a preferred embodiment of the present invention, a kind of judging system of organic additive degradation effect in the gel phase is provided (see image 3 ), including: pyrolysis device 10, used for gel phase pyrolysis, to obtain pyrolysis gas phase products; gas chromatography 20, used for one-dimensional separation of pyrolysis gas phase products; solid-state thermal modulator 30, used to collect one-dimensional The material flowing out of the column is re-injected into the two-dimensional chromatographic column for additional separation; the detector 40 is used for the qualitative analysis of the pyrolysis gas phase products; the data processing and judgment device 50 is used for the quantitative analysis of the pyrolysis products and the gel phase Judgment of the degradation effect of organic additives.

[0050] Preferably, the judgment system also includes an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com