Functional organic compound fertilizer with solid organic wastes as base materials as well as preparation method and application of functional organic compound fertilizer

A technology of organic waste and compound fertilizer, applied in the direction of application, fertilization device, fertilizer mixture, etc., can solve the problems of cockroach secondary pollution, limited species and quantity, and spread of diseases, etc., and achieve the effect of solving perishable and maintaining good soil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

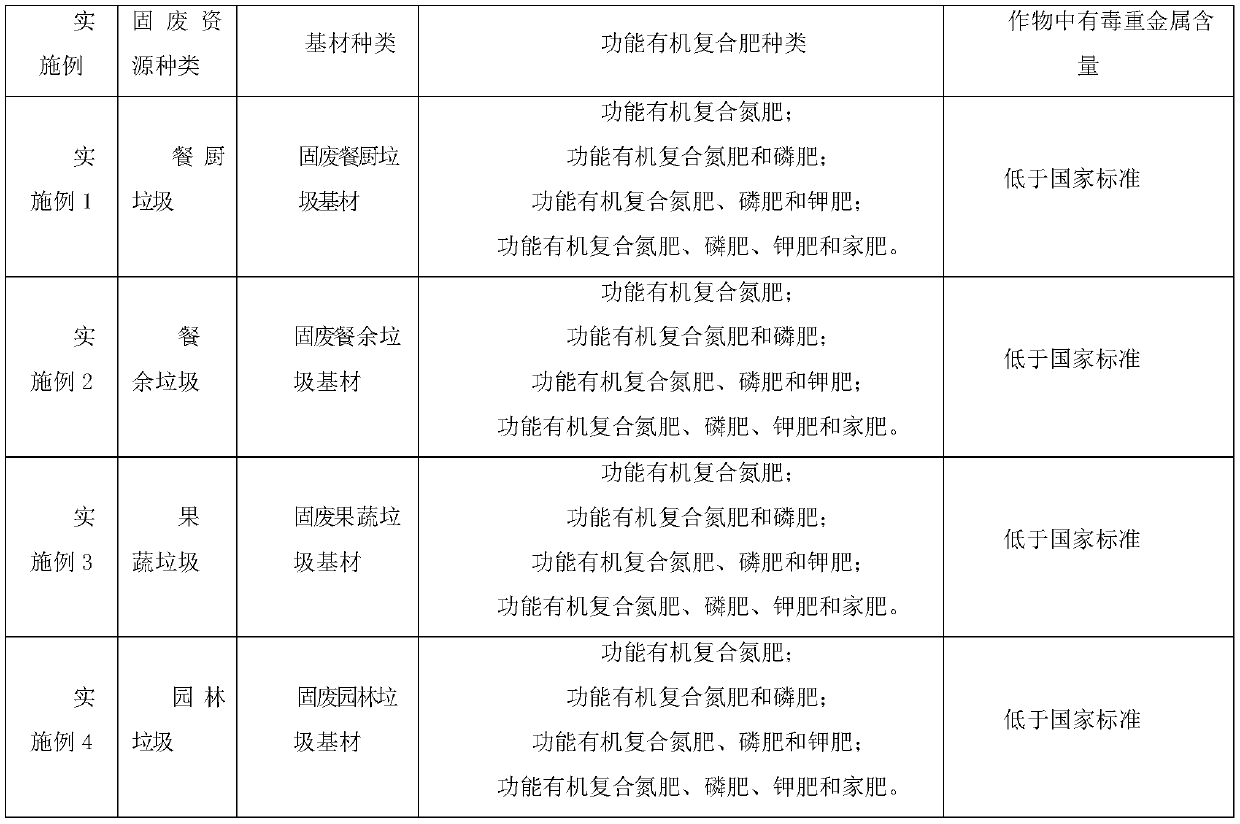

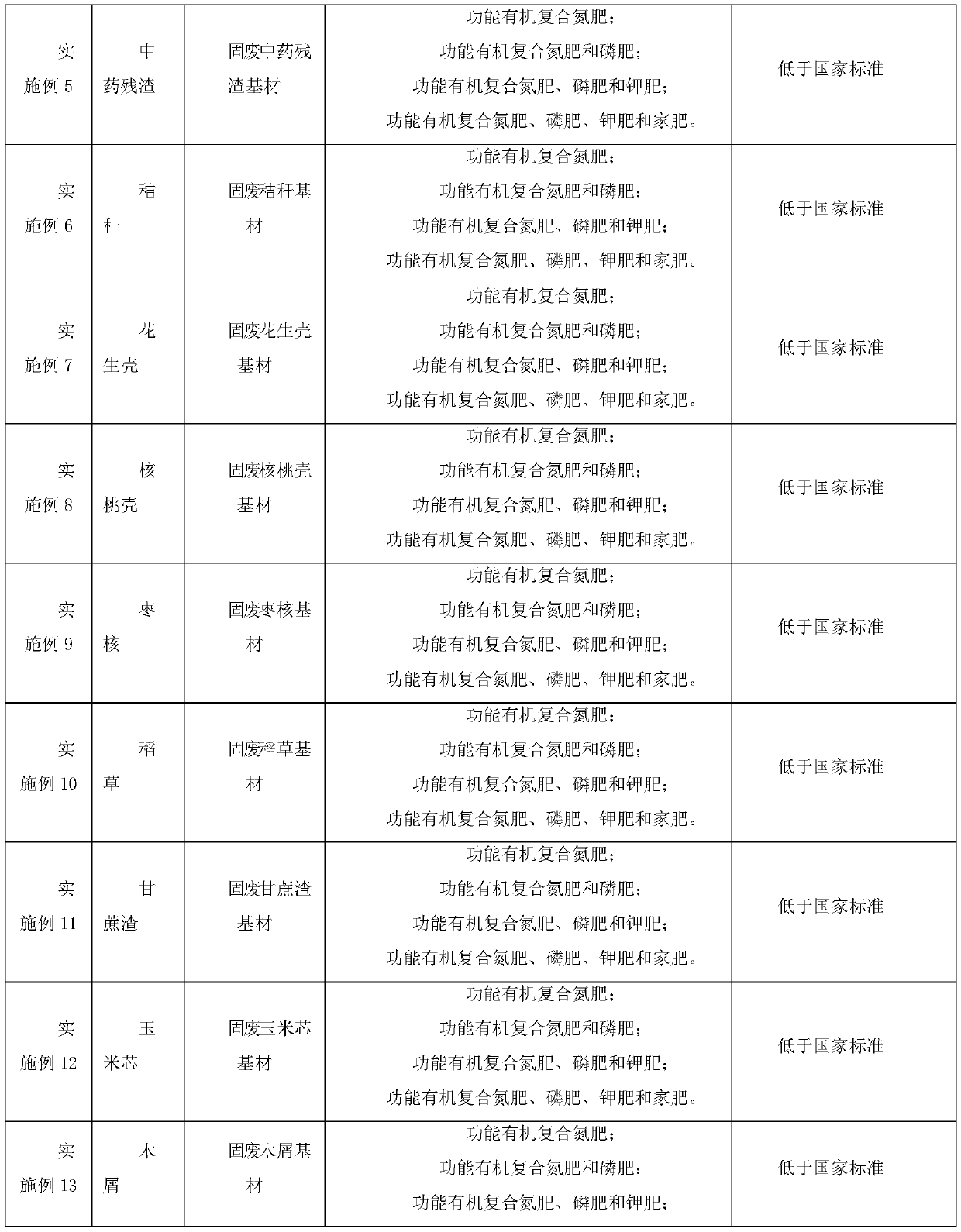

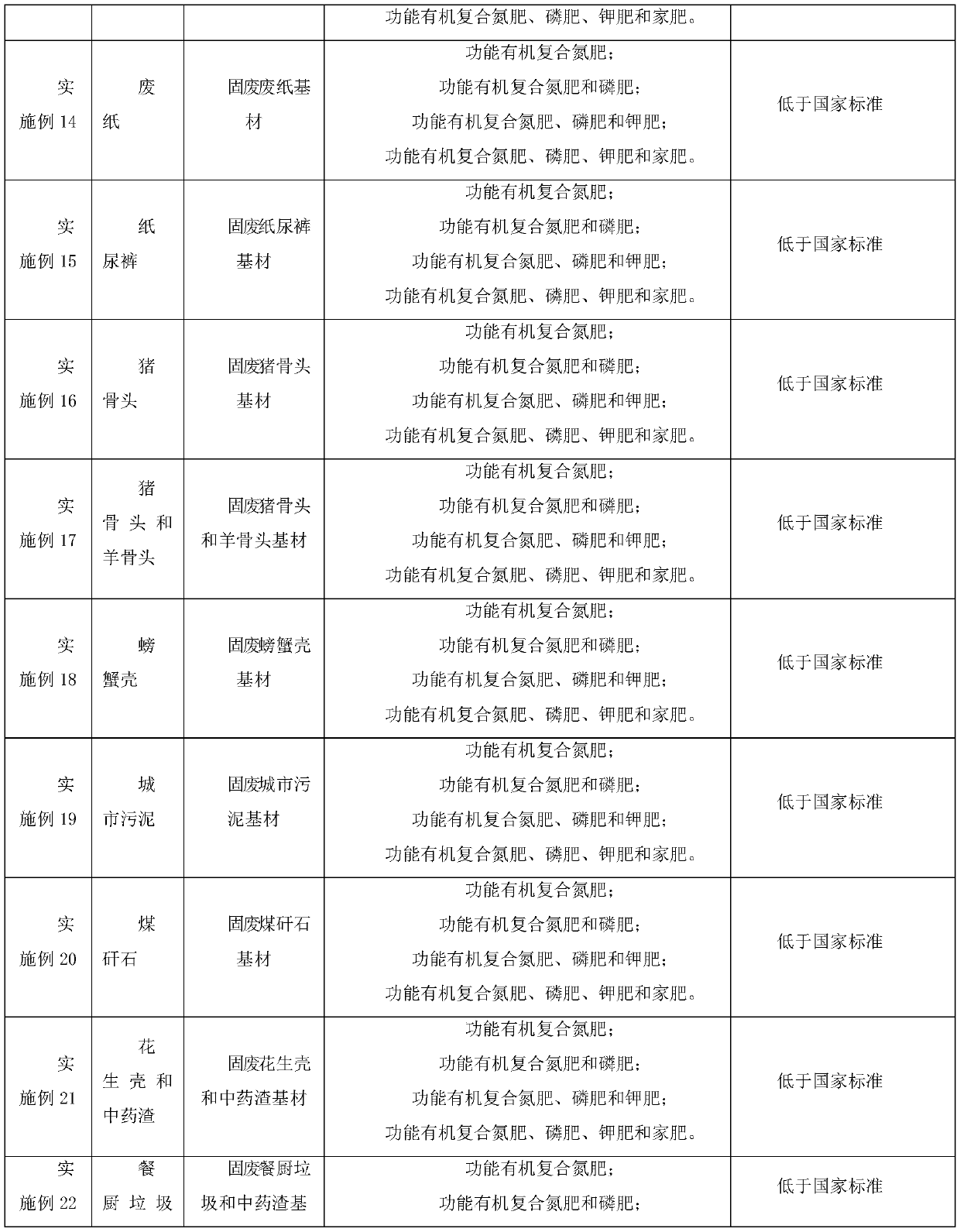

Examples

Embodiment 1

[0039] Substrate Preparation

[0040]Take 100kg of solid food waste, treat it with 500mL of bus disinfectant at 20°C for 0.5 hours, dry at 95°C for 3 hours, and then crush it with a crusher at 30°C to obtain 93kg of particles with an average particle size of 0.2mm.

[0041] Preparation of Functional Organic Compound Fertilizer

[0042] Take 20kg of base material, add 0.001kg of porphyrin and 2kg of urea at 20°C, stir and compound, and shape to obtain functional organic compound fertilizer particles with an average particle size of 2mm;

[0043] Take 20kg of base material, add 0.002kg of phthalocyanine, 2kg of urea, and 1.5kg of phosphate fertilizer at 25°C, stir and compound, and shape to obtain functional organic compound fertilizer particles with an average particle size of 2.5mm;

[0044] Take 20kg of substrate, add 0.05kg of melamine, 2kg of urea, 1.5kg of phosphate fertilizer, and 1kg of potash fertilizer at 25°C, stir and compound, and form to obtain functional organic ...

Embodiment 2

[0048] Substrate Preparation

[0049] Take 200kg of solid food waste, treat it with 800mL of high-efficiency disinfectant at 30°C for 1 hour, dry at 125°C for 2.5 hours, and then crush it with a crusher at 70°C to obtain 195kg of particles with an average particle size of 1mm.

[0050] Preparation of Functional Organic Compound Fertilizer

[0051] Take 30kg of base material, add 0.05kg of tetraazacyclododecane-tetraacetic ethyl ester and 5kg of urea at 25°C, stir and compound, and shape to obtain organic compound fertilizer particles with an average particle size of 5mm;

[0052] Take 25kg of base material, add 0.01kg of tetraazacyclododecane-tetraacetic acid, 3kg of urea, and 2.5kg of phosphate fertilizer at 30°C, stir and compound, and shape to obtain functional organic compound fertilizer particles with an average particle size of 5mm;

[0053] Take 30kg of substrate, add 0.02kg of pentaethylenetetramine, 2.5kg of urea, 2kg of phosphate fertilizer, and 1.1kg of potash fert...

Embodiment 3

[0057] Substrate Preparation

[0058] Take 200kg of solid fruit and vegetable waste, treat it with 800mL of high-efficiency disinfectant at 40°C for 2 hours, dry it at 150°C for 2 hours, and then crush it with a crusher at 30°C to obtain 185kg of particles with an average particle size of 1mm.

[0059] Preparation of Functional Organic Compound Fertilizer

[0060] Take 30kg of substrate, add 0.03kg of melamine and 6kg of urea at 35°C, stir and compound, and form to obtain functional organic compound fertilizer particles with an average particle size of 8mm;

[0061] Take 25kg of base material, add 0.001kg of porphyrin, 3kg of urea, and 3kg of phosphate fertilizer at 30°C, stir and compound, and shape to obtain functional organic compound fertilizer particles with an average particle size of 8mm;

[0062] Take 30kg of base material, add 0.01kg of porphyrin, 2.5kg of urea, 2kg of phosphate fertilizer, and 1.1kg of potassium fertilizer at 25°C, stir and compound, and form into f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com