Device and process for continuously producing dichloropinacolin through differential circulation

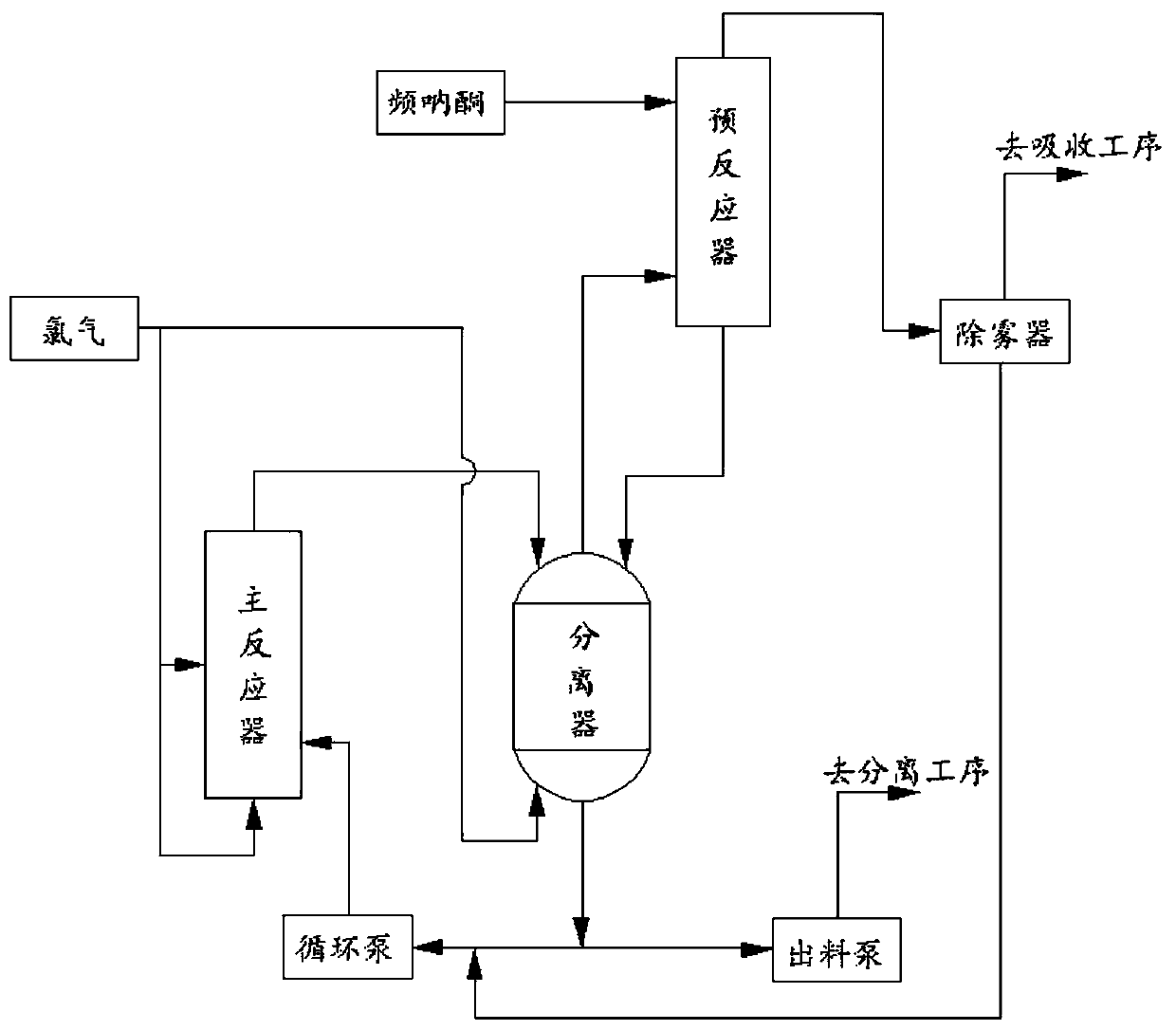

A dichloropinazone and differential technology is applied in the field of devices for continuous production of dichloropinazone by differential circulation, which can solve the problems of large equipment investment, high consumption of raw materials, long production cycle and the like, and achieves increased residence time and production efficiency. High, avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

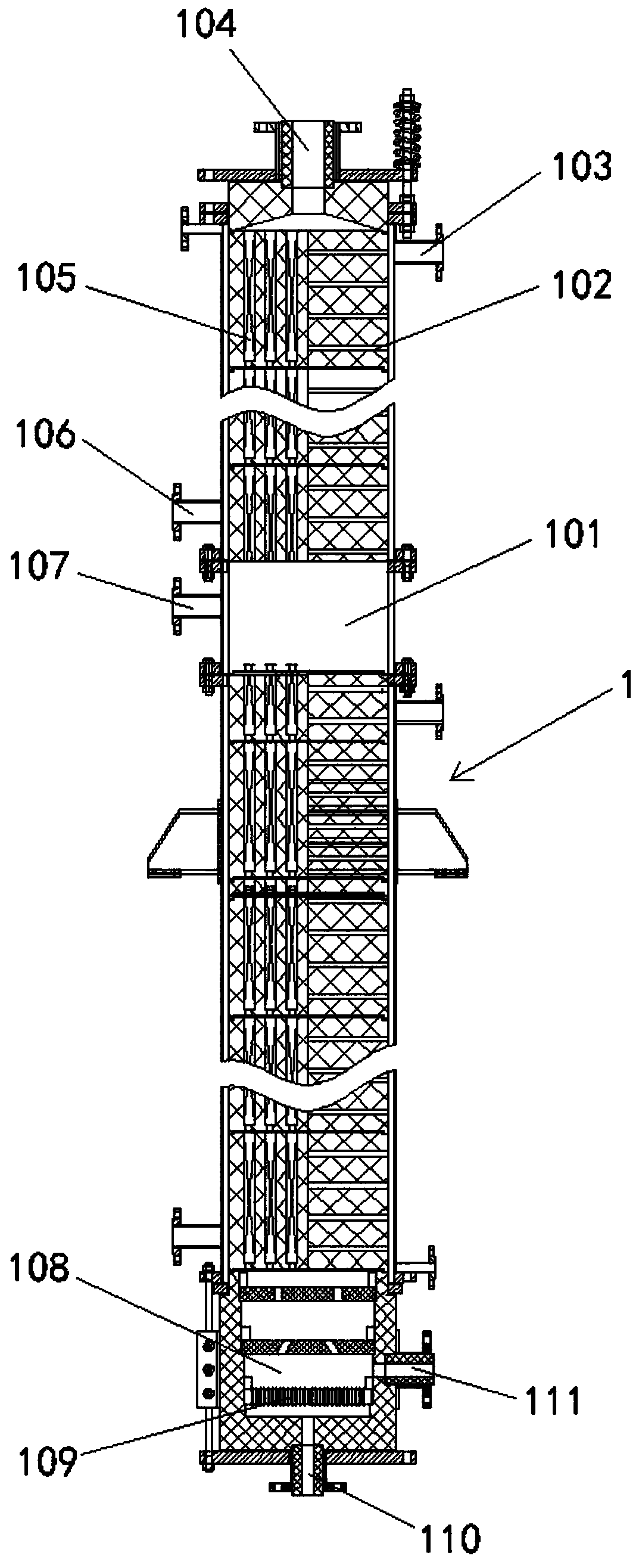

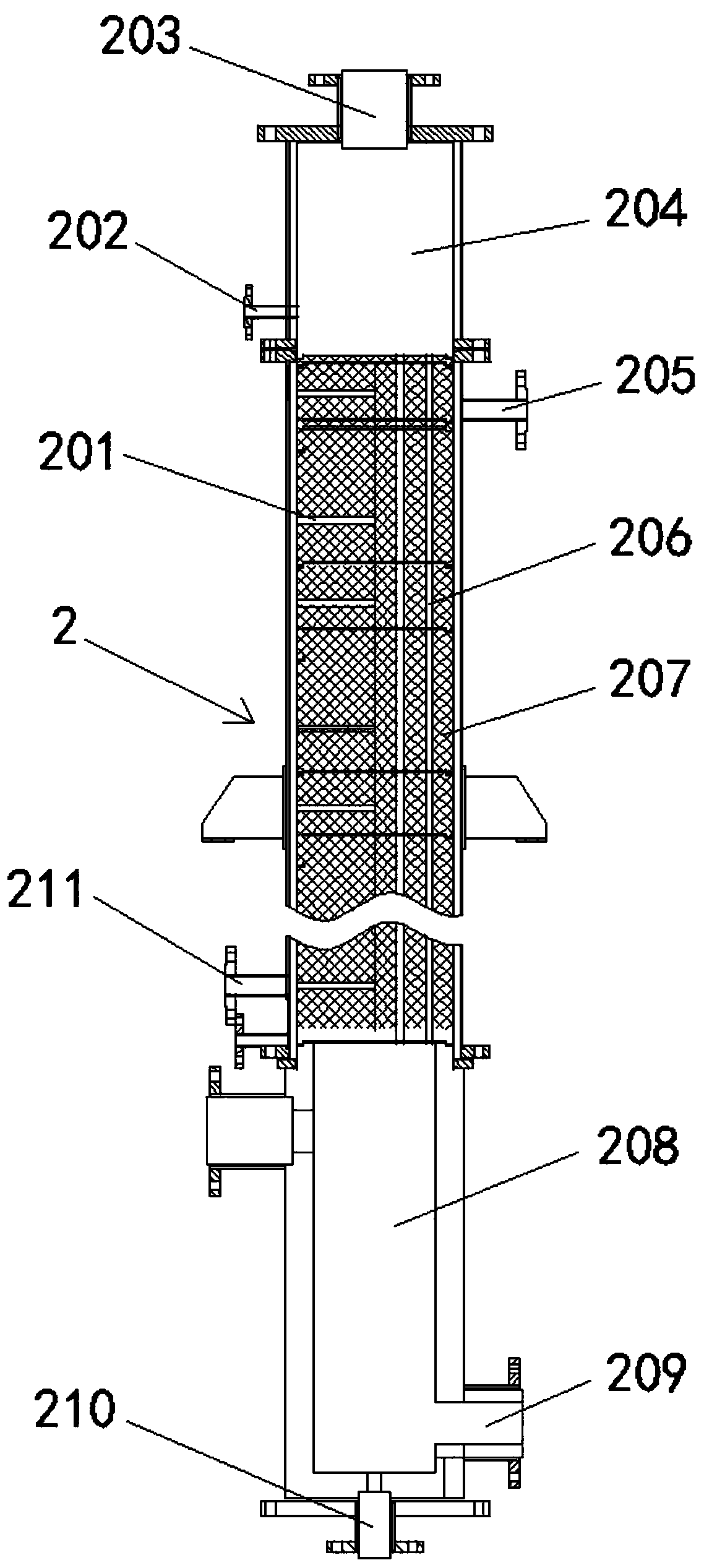

[0050] Step 1: The chlorinated liquid in the separator 3 reacts chemically with the chlorine gas fed into the chlorine inlet 305 of the separator, and is discharged from the outlet 302 of the separator and pressurized by a circulation pump and enters the gas from the liquid inlet 111 of the main reactor. The liquid mixing chamber 108 is fully mixed with the chlorine gas fed into the gas inlet 110 of the main reactor under the action of the high-efficiency mixing structure 109, and the mixed liquid enters the tube side 105 of the main reactor for chemical reaction, and one route of chlorine gas flows from the main reactor The chlorine gas inlet 107 enters into the gas distributor 101 and disperses evenly, then chemically reacts with the mixed liquid in the tube side 105 of the main reactor (the reaction temperature is 35°C, and the reaction pressure is 80KPa), and at the same time passes through the cooling gas in the shell side 102 of the main reactor. Water cooling, the reacte...

Embodiment 2

[0057] Step 1: The chlorinated liquid in the separator 3 reacts chemically with the chlorine gas fed into the chlorine inlet 305 of the separator, and is discharged from the outlet 302 of the separator and pressurized by a circulation pump and enters the gas from the liquid inlet 111 of the main reactor. The liquid mixing chamber 108 is fully mixed with the chlorine gas fed into the gas inlet 110 of the main reactor under the action of the high-efficiency mixing structure 109, and the mixed liquid enters the tube side 105 of the main reactor for chemical reaction, and one route of chlorine gas flows from the main reactor The chlorine gas inlet 107 enters into the gas distributor 101 and disperses evenly, then chemically reacts with the mixed liquid in the tube side 105 of the main reactor (the reaction temperature is 75°C, and the reaction pressure is 250KPa), and at the same time passes through the cooling gas in the shell side 102 of the main reactor. Water cooling, the react...

Embodiment 3

[0064] Step 1: The chlorinated liquid in the separator 3 reacts chemically with the chlorine gas fed into the chlorine inlet 305 of the separator, and is discharged from the outlet 302 of the separator and pressurized by a circulation pump and enters the gas from the liquid inlet 111 of the main reactor. The liquid mixing chamber 108 is fully mixed with the chlorine gas fed into the gas inlet 110 of the main reactor under the action of the high-efficiency mixing structure 109, and the mixed liquid enters the tube side 105 of the main reactor for chemical reaction, and one route of chlorine gas flows from the main reactor The chlorine gas inlet 107 enters into the gas distributor 101 and disperses evenly, then chemically reacts with the mixed liquid in the tube side 105 of the main reactor (the reaction temperature is 55°C, and the reaction pressure is 165KPa), and at the same time passes through the cooling gas in the shell side 102 of the main reactor. Water cooling, the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com