Preparation method of egg yolk lecithin

A technology of egg yolk lecithin and egg yolk powder, which is applied in the direction of edible phospholipid composition, protein food ingredients, food science, etc., can solve the problems of low yield, achieve the effects of improving purity, improving extraction purity, yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

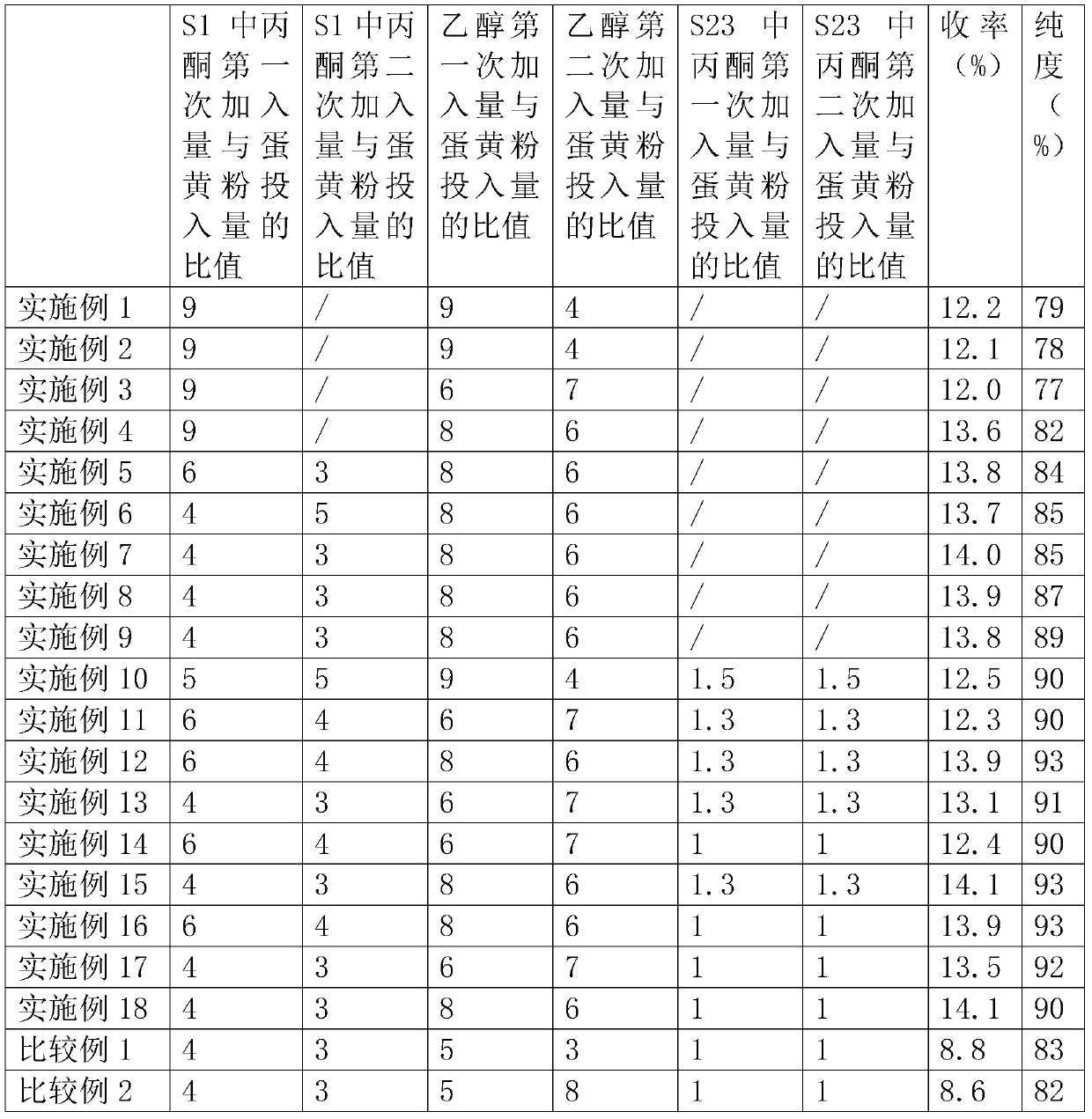

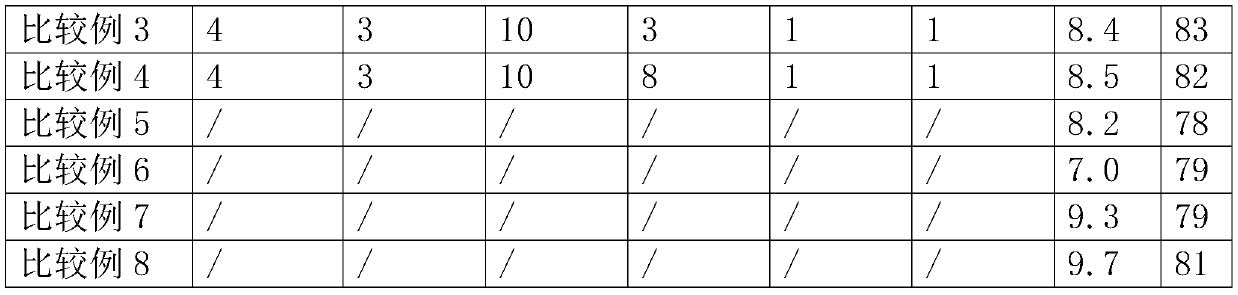

Examples

Embodiment 1

[0036] A preparation method of egg yolk lecithin, comprising the following steps:

[0037] S1, take 100g of egg yolk powder in a 1000ml Erlenmeyer flask, add 900ml of acetone, stir and leach for 1h under normal temperature conditions, filter, discard the filtrate, take the filter residue, and dry the filter residue;

[0038] S2, adding 900ml of ethanol with a mass concentration of 95% to the dried filter residue in S1, leaching for 1h at a temperature of 18°C, filtering, saving the filtrate for subsequent use, taking the filter residue and adding 400ml of a mass concentration of 95% to the filter residue % ethanol, leached for 1 h at a temperature of 18°C, filtered, the filtrate was combined with the filtrate filtered for the first time, and the filter residue was discarded;

[0039] S3. Take the filtrate combined twice in S2 and concentrate it to a paste under reduced pressure at 40°C, then add the paste-like filtrate into a freeze dryer, dry it under vacuum for 24 hours, and...

Embodiment 2

[0041] A preparation method of egg yolk lecithin, comprising the following steps:

[0042] S1, take 100g of egg yolk powder in a 1000ml Erlenmeyer flask, add 900ml of acetone, stir and leach for 1h under normal temperature conditions, filter, discard the filtrate, take the filter residue, and dry the filter residue;

[0043] S2, adding 900ml of ethanol with a mass concentration of 90% to the dried filter residue in S1, leaching for 1h at a temperature of 18°C, filtering, saving the filtrate for subsequent use, taking the filter residue and adding 400ml of a mass concentration of 90% to the filter residue % ethanol, leached for 1 h at a temperature of 18°C, filtered, the filtrate was combined with the filtrate filtered for the first time, and the filter residue was discarded;

[0044] S3. Take the filtrate combined twice in S2 and concentrate it to a paste under reduced pressure at 40°C, then add the paste-like filtrate into a freeze dryer, dry it under vacuum for 24 hours, and...

Embodiment 3

[0046] A preparation method of egg yolk lecithin, comprising the following steps:

[0047] S1, take 100g of egg yolk powder in a 1000ml Erlenmeyer flask, add 900ml of acetone, stir and leach for 1h under normal temperature conditions, filter, discard the filtrate, take the filter residue, and dry the filter residue;

[0048] S2, adding 600ml of ethanol with a mass concentration of 90% to the dried filter residue in S1, leaching for 1h at a temperature of 18°C, filtering, saving the filtrate for subsequent use, taking the filter residue and adding 700ml of 90% mass concentration to the filter residue % ethanol, leached for 1 h at a temperature of 18°C, filtered, the filtrate was combined with the filtrate filtered for the first time, and the filter residue was discarded;

[0049] S3, take the filtrate combined twice in S2 and concentrate it to a paste under reduced pressure at 40°C, then add the paste-like filtrate into a freeze dryer, dry it under vacuum for 24 hours, and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com