A kind of straw pretreatment method for extracting hemicellulose

A technology of straw pretreatment and hemicellulose is applied in the field of extraction of active components in straw, which can solve the problems of uneconomical application and high power consumption, and achieve the effects of low power consumption, increased contact area, and improved extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 100kg of bagasse to the extraction tank. After the extraction tank is evacuated, 1000L of pretreatment liquid (concentration of 5g / L sodium hydroxide aqueous solution) is sucked in at the ratio of solid-liquid ratio of 1g:10mL, and soaked for 10h at room temperature. After that, 330L of free lye in bagasse is discharged, and the discharged solution is dark brown. The remaining material in the extraction tank is sent to a high-concentration disc-type paper refiner. The material is ground into filaments with a diameter of 0.1-0.5mm. Centrifuge the material obtained from the slurry to discharge the free lye in the ground fiber. Collect 550L of the liquid, add 300L of water to the bagasse, stir, mix and wash, and centrifuge again to discharge 295L of alkali-containing washing water. Combine the three liquids to obtain 1175L. No xylan was detected. ; The collected solids are the processed bagasse fibers, and the bagasse fibers obtained are soft and dense.

Embodiment 2

[0024] Weigh 50 kg of bagasse fibers treated as described in Example 1 and 50 kg of bagasse fibers treated as described in Comparative Example 1 to extract 50 kg of hemicellulose by the alkaline method.

[0025] The extraction conditions are: solid-liquid ratio 1g:5mL, the lye used for extraction is an aqueous NaOH solution with a concentration of 8% (w / v), the extraction time is 12h, and the temperature is room temperature.

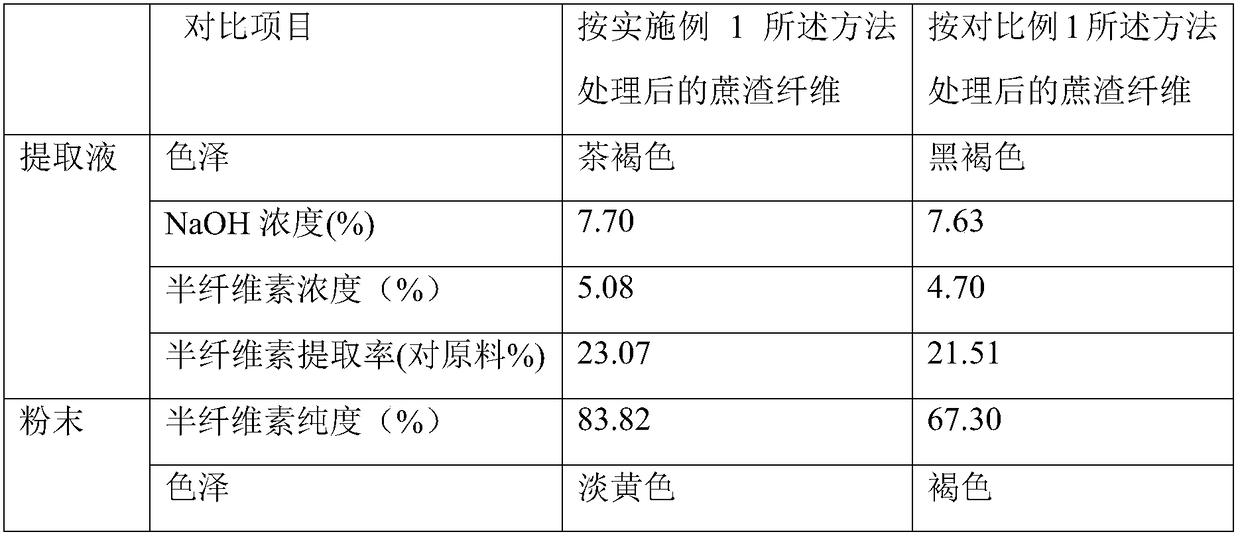

[0026] Then compare the NaOH concentration and color of the obtained hemicellulose extract, and use 95% (v / v) ethanol alcohol precipitation equivalent to 3 times the volume of the extract, 75% ethanol to wash the hemicellulose, and finally the dry hemicellulose The color, purity and extraction rate of the plain powder were compared, and the results are shown in Table 1.

[0027] Table 1:

[0028]

[0029] It can be seen from Table 1 that when the bagasse treated by the method of the present invention is extracted and refined by the conventional alkaline method, ...

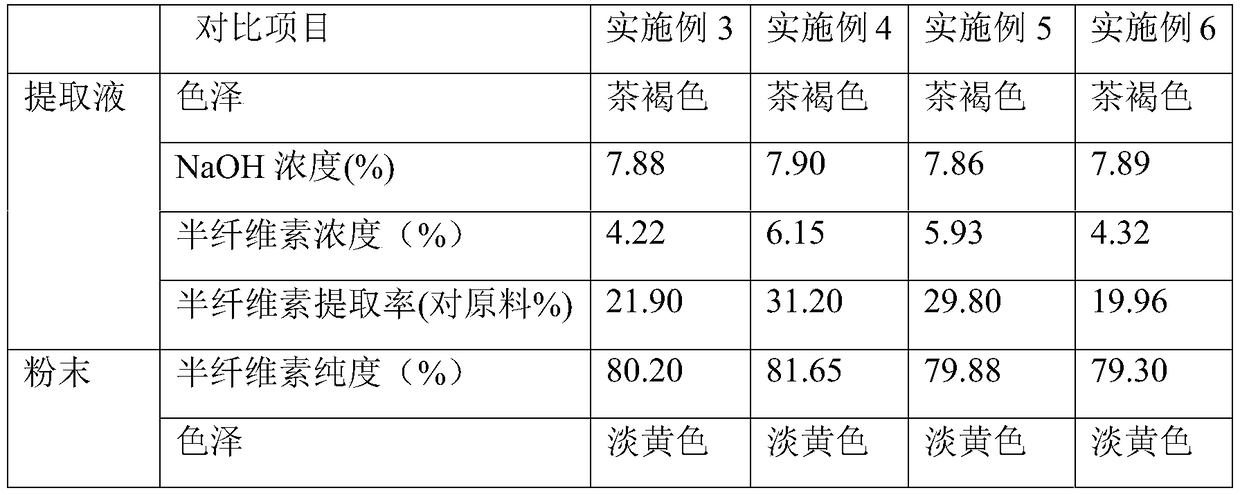

Embodiment 3

[0031] Cut corn stalks into small sections with a length of 1 to 3 cm, weigh 100 kg and put it into the extraction tank, add 1000 L of pretreatment solution (concentration of 5g / L sodium hydroxide aqueous solution) at the ratio of solid-to-liquid ratio of 1g: 10mL, and heat to Soak for 1h after 60℃. After that, 330L of free lye in the material is discharged, the solution is dark brown, and the remaining material in the extraction tank is sent to a high-concentration disc paper refiner, and the material is ground into filaments with a diameter of 0.1-0.5mm. The material obtained from the slurry was centrifuged to discharge the free lye in the ground fiber, and 560L of the liquid was collected. The bagasse was added with 300L of water, stirred, mixed and washed, and centrifuged again to discharge 298L of alkali-containing washing water. The three liquids were combined to obtain 1188L. No xylan was detected. ; Collect the solid, that is, the processed cornstalk fiber, the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com