A kind of ferrous sucrose and preparation method thereof

A technology of sucrose and ferrous iron, which is applied in the field of preparation of organic complexes, can solve the problems of iron-deficiency yellowing of plant leaves, not being absorbed and utilized by plants, and difficulty in maintaining divalent forms, so as to achieve less raw materials, shorten production time, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

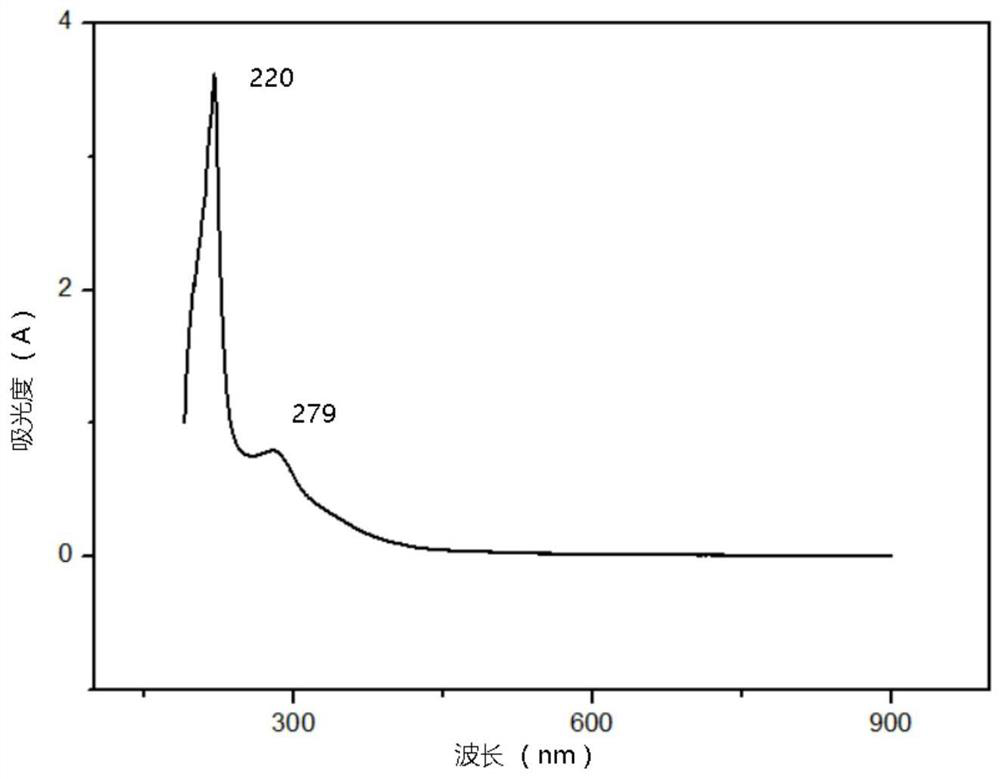

Image

Examples

Embodiment 1

[0039] The present embodiment provides a kind of preparation method of ferrous sucrose, and described preparation method comprises the steps:

[0040] 1) Dissolve 1 kg of sucrose in 8 times the weight of tetrahydrofuran solvent, and stir at 400 rpm for 10 min at a temperature of 40°C;

[0041] 2) Dissolve 5kg of ferrous chloride in THF solvent twice the weight, and stir at 600rpm for 5min at a temperature of 40°C;

[0042] 3) Mix the two solutions prepared in step 1) and step 2) uniformly, place them at a temperature of 100° C., stir at a rate of 400 to 600 rpm, and react for 8 hours to obtain a ferrous sucrose solution; Put the iron solution at a temperature of 40°C, distill under reduced pressure, take the solid phase, and collect the powder by spray drying to obtain ferrous sucrose;

[0043] 4) Heat and sterilize the ferrous sucrose obtained in step 3) at a temperature of 121° C. for 20 minutes, and cool to obtain ferrous sucrose. The yield was 86% and the purity was 98%....

Embodiment 2

[0045] The present embodiment provides a kind of preparation method of ferrous sucrose, and described preparation method comprises the steps:

[0046]1) Dissolve 1 kg of sucrose in 8 times the weight of dimethyl sulfoxide solvent, and stir at 800 rpm for 10 min at a temperature of 50 ° C;

[0047] 2) Dissolve 3 kg of ferrous sulfate in 2.3 times the weight of dimethyl sulfoxide solvent, and stir at 1000 rpm for 15 min at a temperature of 40 ° C;

[0048] 3) Mix the two solutions prepared in step 1) and step 2) uniformly, place them at a temperature of 110° C., stir at a rate of 400 to 600 rpm, and react for 12 hours to obtain a ferrous sucrose solution; The iron solution is placed at a temperature of 50°C, distilled under reduced pressure, the solid phase is taken, and the powder is collected by spray drying to obtain ferrous sucrose;

[0049] 4) Heat and sterilize the ferrous sucrose obtained in step 3) at a temperature of 121° C. for 25 minutes, and cool to obtain ferrous s...

Embodiment 3

[0052] The present embodiment provides a kind of preparation method of ferrous sucrose, and described preparation method comprises the steps:

[0053] 1) Dissolve 3 kg of sucrose in 3.4 times the weight of acetonitrile solvent, and stir at 1200 rpm for 15 min at a temperature of 60 ° C;

[0054] 2) Dissolve 7.5kg of ferrous chloride in 1.07 times the weight of acetonitrile solvent, and stir at 1600rpm for 20min at a temperature of 40°C;

[0055] 3) Mix the two solutions prepared in step 1) and step 2) uniformly, place them at a temperature of 120° C., stir at a rate of 400 to 600 rpm, and react for 16 hours to obtain ferrous sucrose solution; Place the iron solution at a temperature of 60°C, distill under reduced pressure, take the solid phase, and collect the powder by spray drying to obtain ferrous sucrose;

[0056] 4) Heat and sterilize the ferrous sucrose obtained in step 3) at a temperature of 121° C. for 35 minutes, and cool to obtain ferrous sucrose. The yield was 86%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com