Aqueous fluorine-containing resin and preparation method thereof

A fluorine-containing resin, water-based technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of low water contact angle and complex preparation, and achieve the effect of high contact angle, good film-forming performance and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

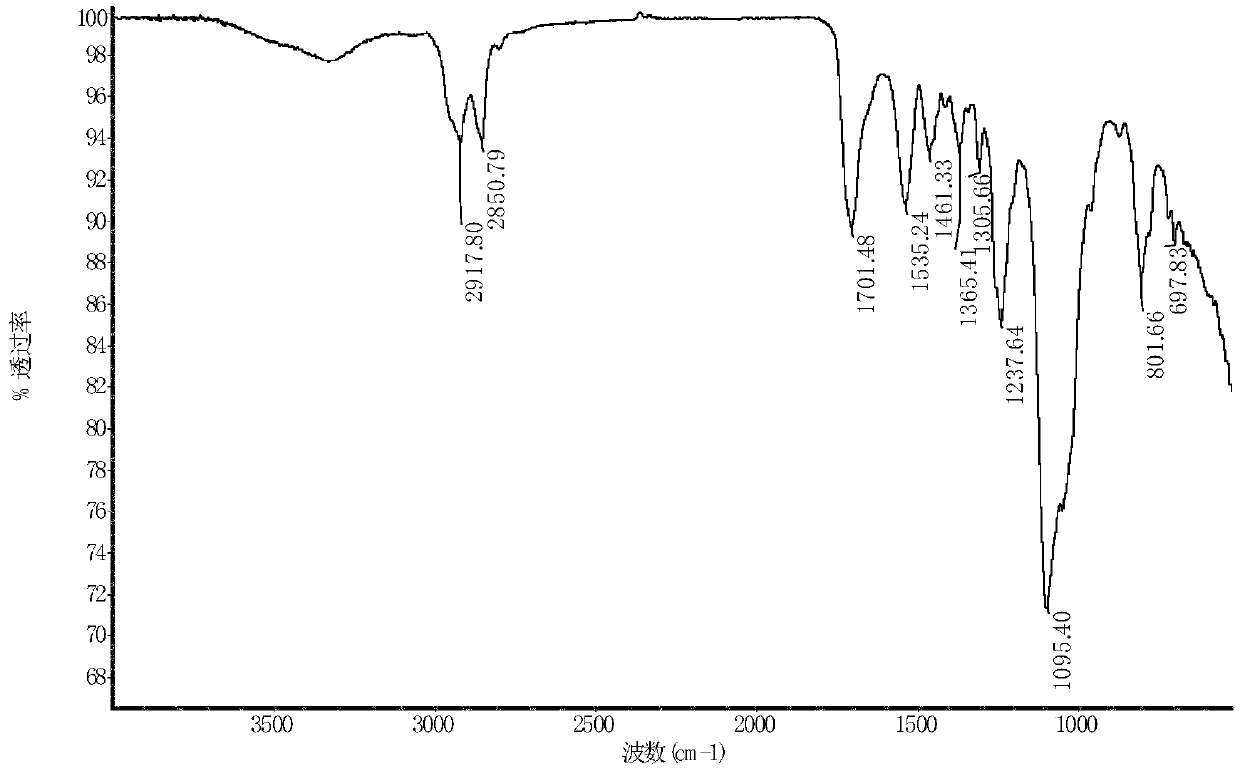

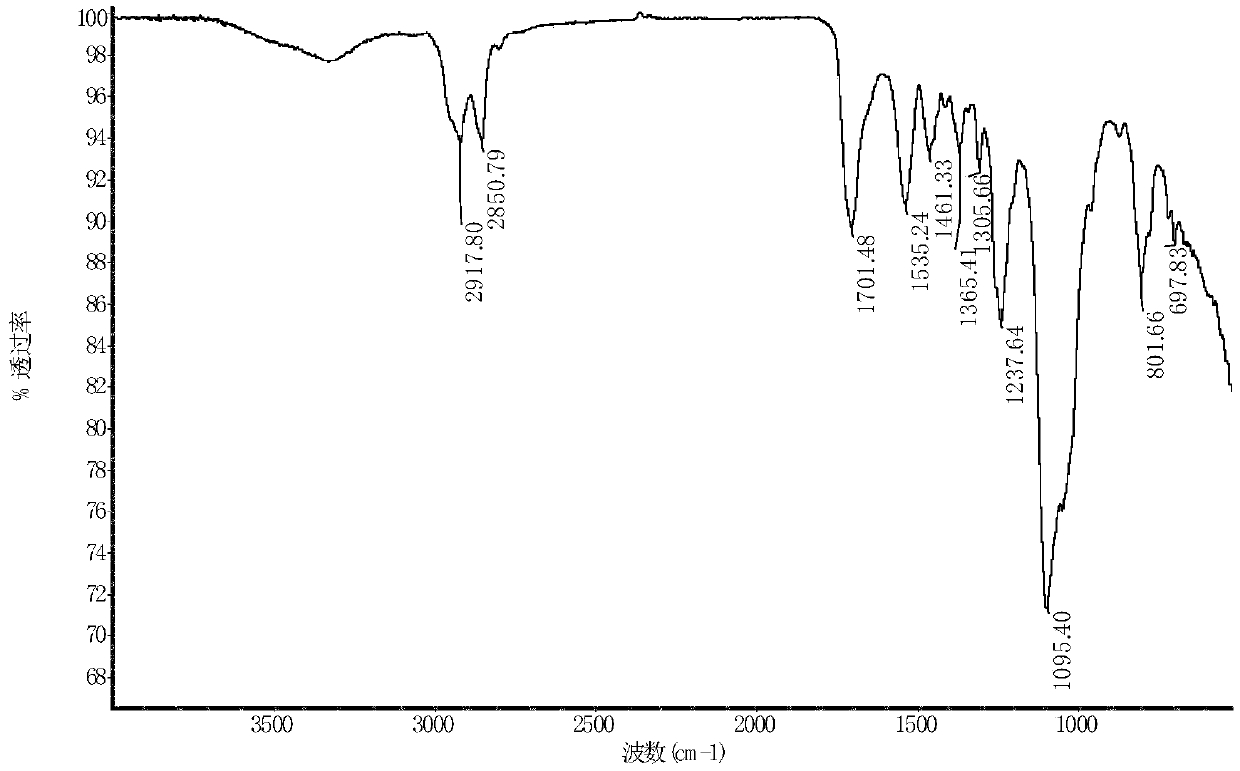

Image

Examples

Embodiment 1

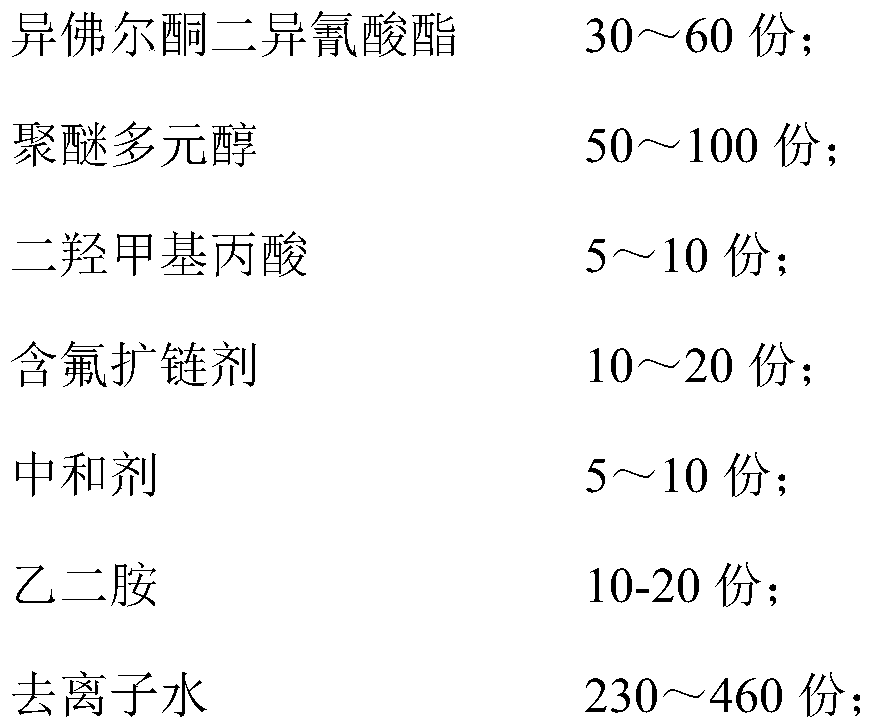

[0037] A water-based fluorine-containing resin, calculated in parts by weight, its preparation raw materials include:

[0038]

[0039] Wherein, the polyether polyol is PTMG1000; the neutralizer is triethylamine. Calculated in parts by weight, the raw materials for the preparation of the fluorine-containing chain extender include hexafluoroisopropanol, isophorone diisocyanate, trimethylolpropane, A solvent and a catalyst, wherein the solvent is acetone; the catalyst is dibutyltin dilaurate.

[0040] The concrete steps of the preparation method of described aqueous fluororesin are:

[0041] 1) Add hexafluoroisopropanol, isophorone diisocyanate, and the catalyst into the four-necked flask in sequence, raise the temperature to 30°C, and add the solvent into the four-necked flask at a rate of 0.05ml / s in proportion, React for 1 h under stirring, then add trimethylolpropane in proportion, raise the temperature to 70°C, and react for 5 h under stirring to obtain the fluorine-co...

Embodiment 2

[0054] A water-based fluorine-containing resin, calculated in parts by weight, its preparation raw materials include:

[0055]

[0056] Wherein, the polyether polyol is a mixture of PTMG1000 and N210 in a mass ratio of 1:1. Described neutralizing agent is triethylamine. Calculated in parts by weight, the raw materials for the preparation of the fluorine-containing chain extender include hexafluoroisopropanol, isophorone diisocyanate, trimethylolpropane, Solvent and catalyst, wherein, described solvent is the mixture that acetone, ethyl acetate form by volume ratio 1:1; Described catalyst is dibutyltin dilaurate;

[0057] The specific steps of the preparation method of the water-based fluorine-containing resin are as follows: 1) adding hexafluoroisopropanol, isophorone diisocyanate, and catalyst into a four-necked flask in proportion, raising the temperature to 50°C, and adding The solvent was added into the four-necked flask at a rate of 0.1ml / s, stirred and reacted for 1...

Embodiment 3

[0063] A water-based fluorine-containing resin, calculated in parts by weight, its preparation raw materials include:

[0064]

[0065] Wherein, the polyether polyol is N210. Described neutralizing agent is triethylamine. Calculated in parts by weight, the raw materials for the preparation of the fluorine-containing chain extender include hexafluoroisopropanol, isophorone diisocyanate, trimethylolpropane, Solvent and catalyst, wherein, described solvent is ethyl acetate; Described catalyst is dibutyltin dilaurate;

[0066] The specific steps of the preparation method of the water-based fluorine-containing resin are as follows: 1) adding hexafluoroisopropanol, isophorone diisocyanate, and a catalyst into a four-necked flask in proportion, raising the temperature to 35°C, and adding The solvent was added into the four-necked flask at a speed of 0.08ml / s, and reacted for 2 hours under stirring, then trimethylolpropane was added in proportion, the temperature was raised to 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com