Insulating ink for packaging of semiconductor passive elements

A passive component and insulating ink technology, applied in the field of ink, can solve the problems of poor thermal stability, high cost, and easy ion migration, etc., and achieve good weather resistance and meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with specific embodiments.

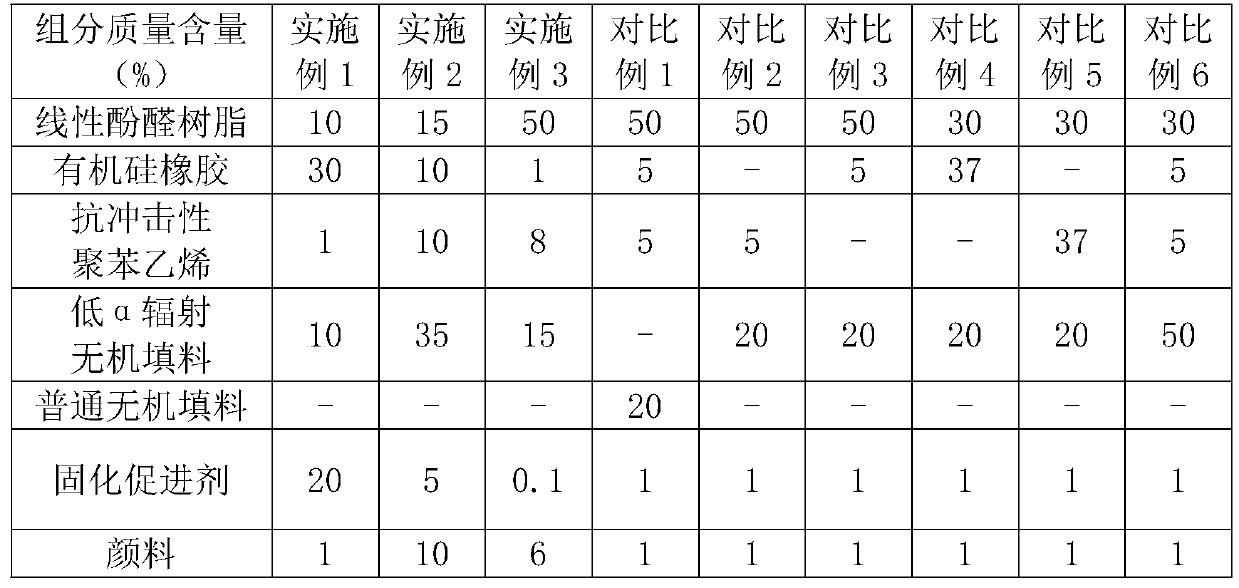

[0018] Stir and mix the raw materials according to the ratio in Table 1. After fully stirring and mixing, through ball milling, sand milling or three-roll grinding, or ultrasonic dispersion, or high-speed rotation, a uniformly dispersed liquid mixture is obtained, and then filtered and quality inspected. and subpackaging to obtain insulating ink for passive component packaging with a fineness of 10 μm or less, and a viscosity of 1-120,000 mPa.s, preferably 3-90,000 mPa.s. The insulating inks of Examples 1-3 and Comparative Examples 1-6 were prepared.

[0019] Table 1:

[0020]

[0021]

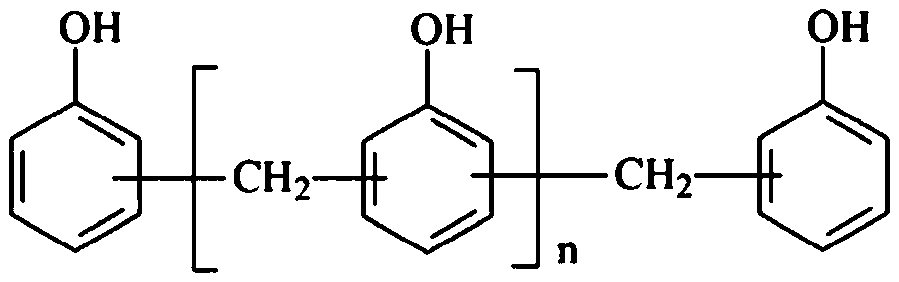

[0022] Among them, the novolac resin used in the examples is PF-8210 from Shandong Moore Chemical Co., Ltd., the silicone rubber is RC-704 from Liyang Ruicheng New Material Co., Ltd., and the impact-resistant polystyrene is Trinseo polymer. STYRON A-TECH HIPS of (Zhangjiag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com