Ultra-low emission purification treatment system of converter primary dry method dedusting emission smoke

A dry dust removal and purification treatment technology, applied in the manufacture of converters, etc., can solve problems such as difficulties in transformation, achieve significant power saving effects, increase water consumption, and save transformation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of this embodiment will be described below in conjunction with the accompanying drawings.

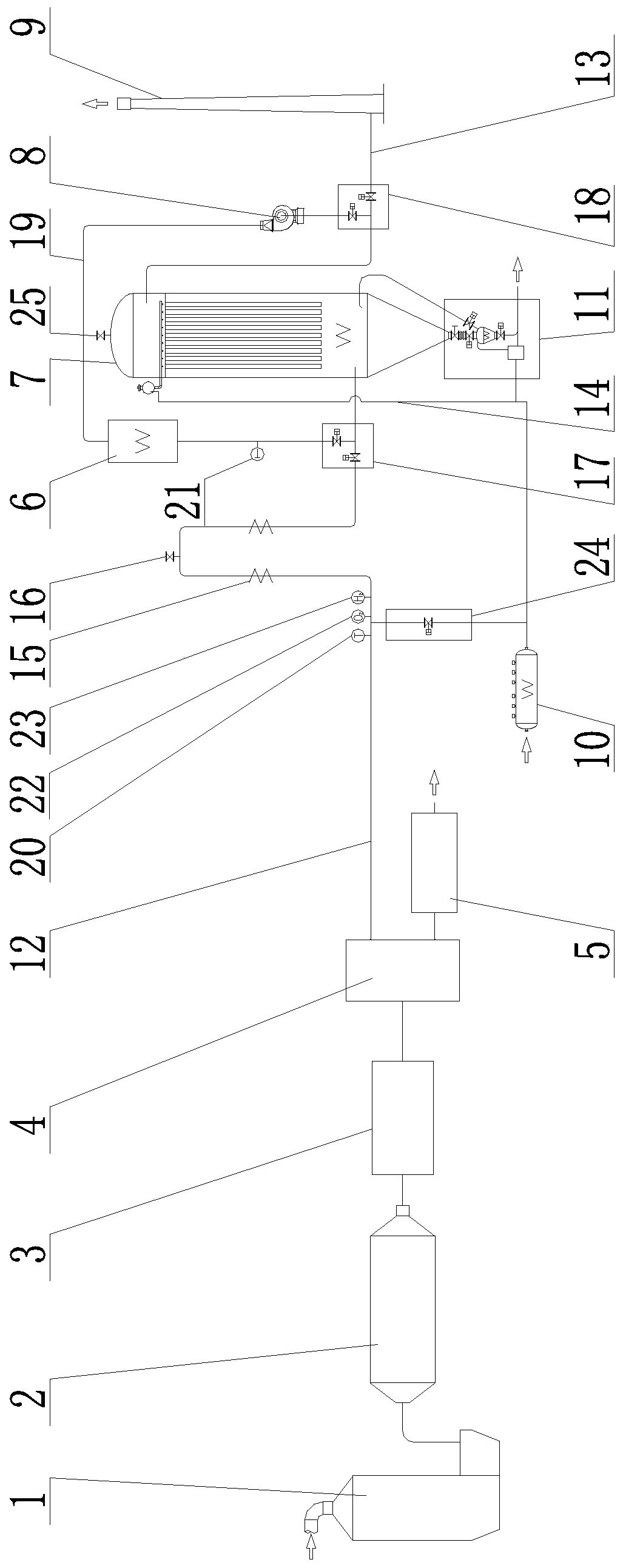

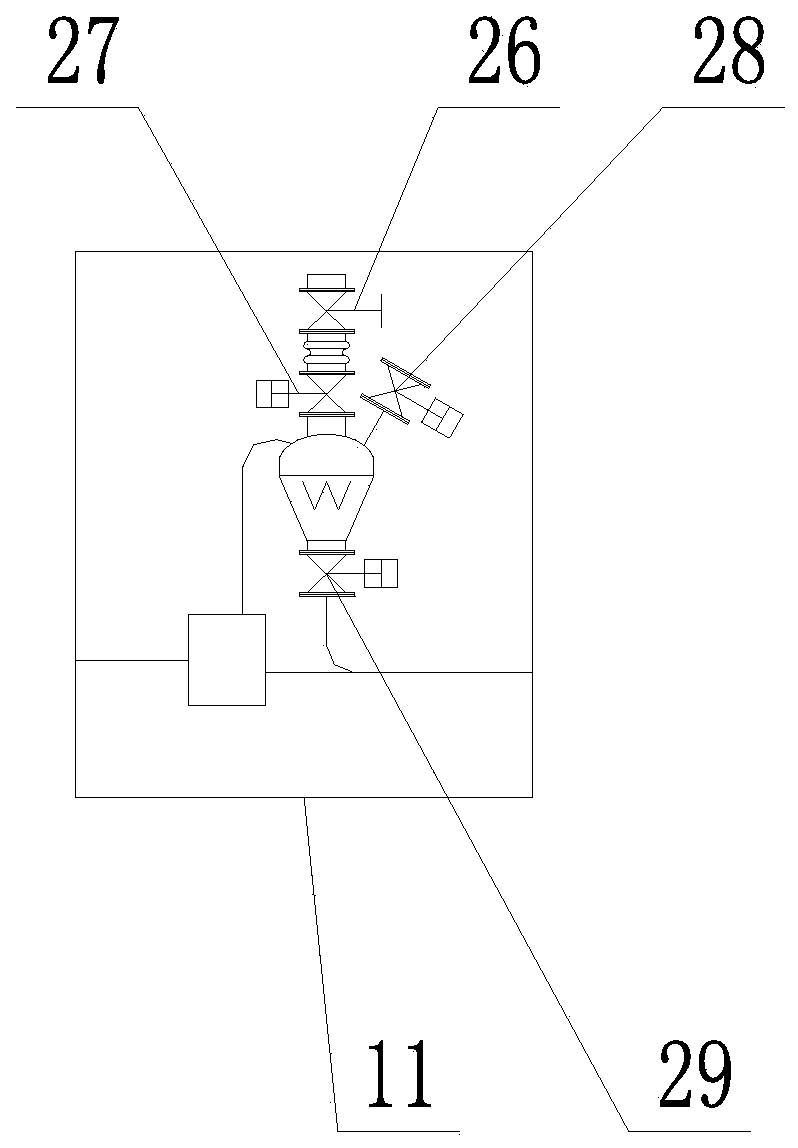

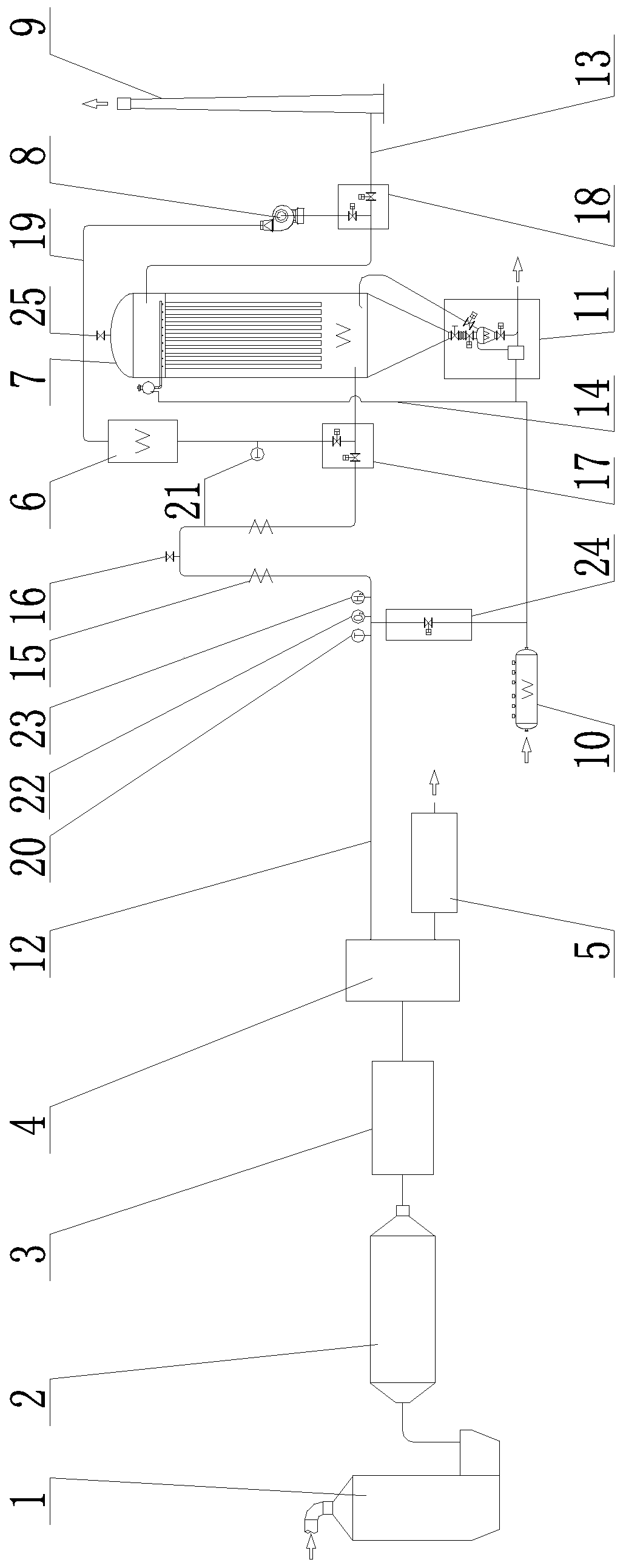

[0022] figure 1 It is a schematic diagram of the present invention. Such as figure 1 As shown, an ultra-low emission purification treatment system for primary dry dedusting and releasing flue gas of a converter, including an evaporative cooler 1, an electrostatic precipitator 2, a first fan 3, a switching station 4, a gas cooler 5, and a heat exchanger 6 , Pulse bag filter 7, second fan 8, release chimney 9, nitrogen heater 10 and pneumatic ash delivery device 11. The ultra-low emission purification treatment system for primary dry dust removal and flue gas emission of the converter is controlled by an automatic control device.

[0023] The outlet of the evaporative cooler 1 and the inlet of the electrostatic precipitator 2 are connected together through a gas pipeline. The outlet of the electrostatic precipitator 2 is connected with the inlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com