Method for recovering lead, copper and arsenic from white smoke dust

A technology of white smoke, lead and copper, applied in the field of recycling lead, copper and arsenic, can solve the problems of low recycling efficiency, recycling single metal, polluting the environment, etc., and achieve the effect of reducing the amount of discharge and treatment, reducing waste of resources, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

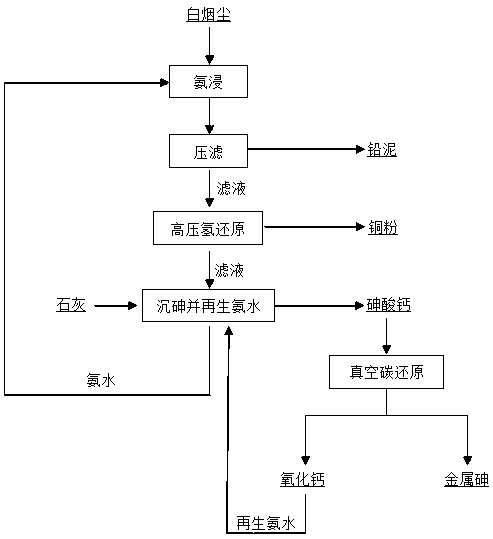

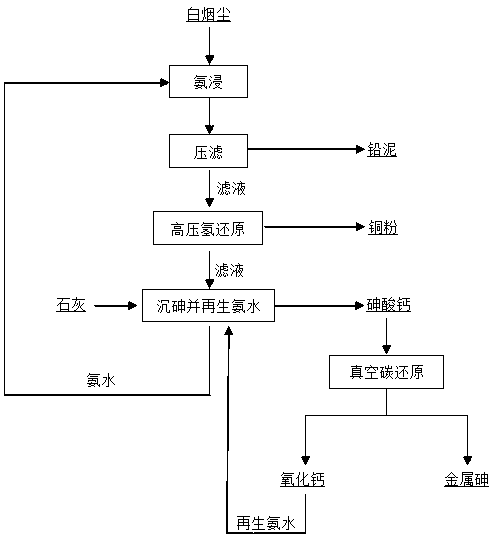

[0012] Embodiment: the present invention provides a kind of method that reclaims lead copper arsenic from white smoke dust, and concrete steps are as follows:

[0013] (1) Pass the white smoke into ammonia water for ammonia immersion treatment, pressurize the product after the reaction is completed, and wash the obtained solid to become lead sludge;

[0014] (2) Pass hydrogen gas into the filtrate obtained in step (1) and pressurize, perform high-pressure hydrogen reduction treatment, filter the product after the reaction is completed, wash and dry the obtained solid to obtain copper powder;

[0015] (3) Add lime to the filtrate obtained in step (2), carry out arsenic precipitation and regenerate ammonia water treatment, that is, add lime to react, and filter the obtained product after the reaction is completed, and the filtered filtrate is used as step (1) The ammonia water in the process is recycled, and the filtered solid is washed and dried to obtain calcium arsenate;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com