Method for recycling viscose fiber acidic wastewater by using two-stage special membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

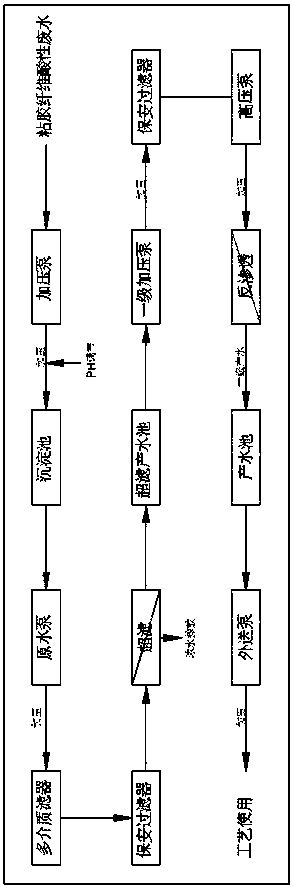

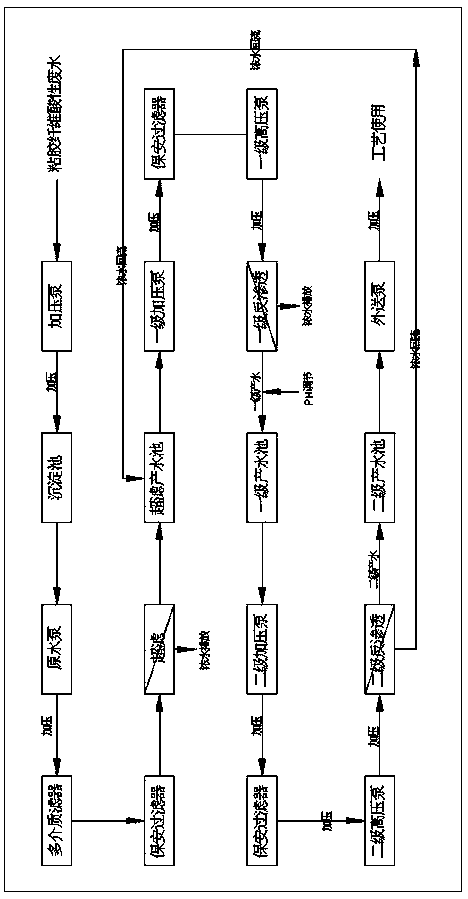

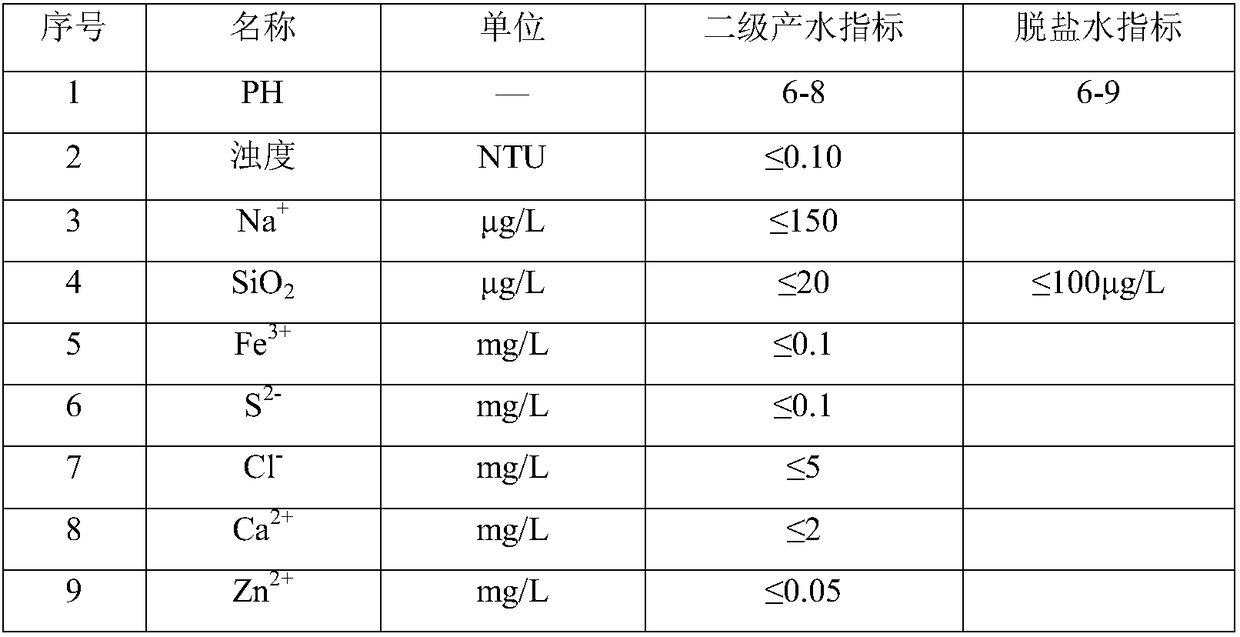

[0018] Such as figure 2 As shown, a method for recycling and reusing viscose fiber acid wastewater by using a two-stage special membrane, the specific steps are: sending raw viscose fiber acid wastewater through a pressurized pump into a sedimentation tank for precipitation to settle suspended solids in the precipitation. The water in the sedimentation tank is pressurized by the raw water pump, and then the product water filtered by the multi-media filter, the precision filter and the ultrafiltration system is sent to the ultrafiltration production pool. The ultrafiltration production pool water is pressurized by the primary pressure pump and filtered through the precision filter. The first-level high-pressure pump pressurizes and the first-level special reverse osmosis membrane system treats and intercepts some sulfate radicals in the water, and at the same time increases the pH value of the water produced by the first-level special reverse osmosis membrane system (about 1), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com