Method of manufacturing clad layer on basis of vibration-assistant ultrahigh-speed laser cladding technology

A laser cladding, ultra-high-speed technology, applied in the direction of coating, metal material coating process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

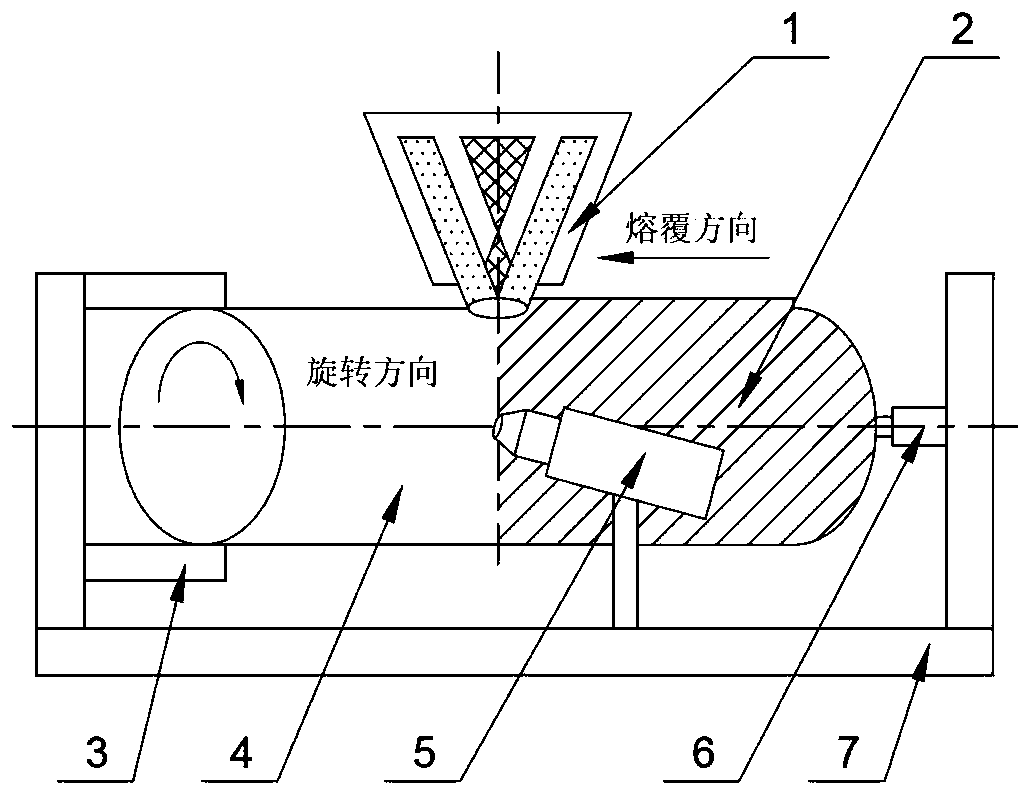

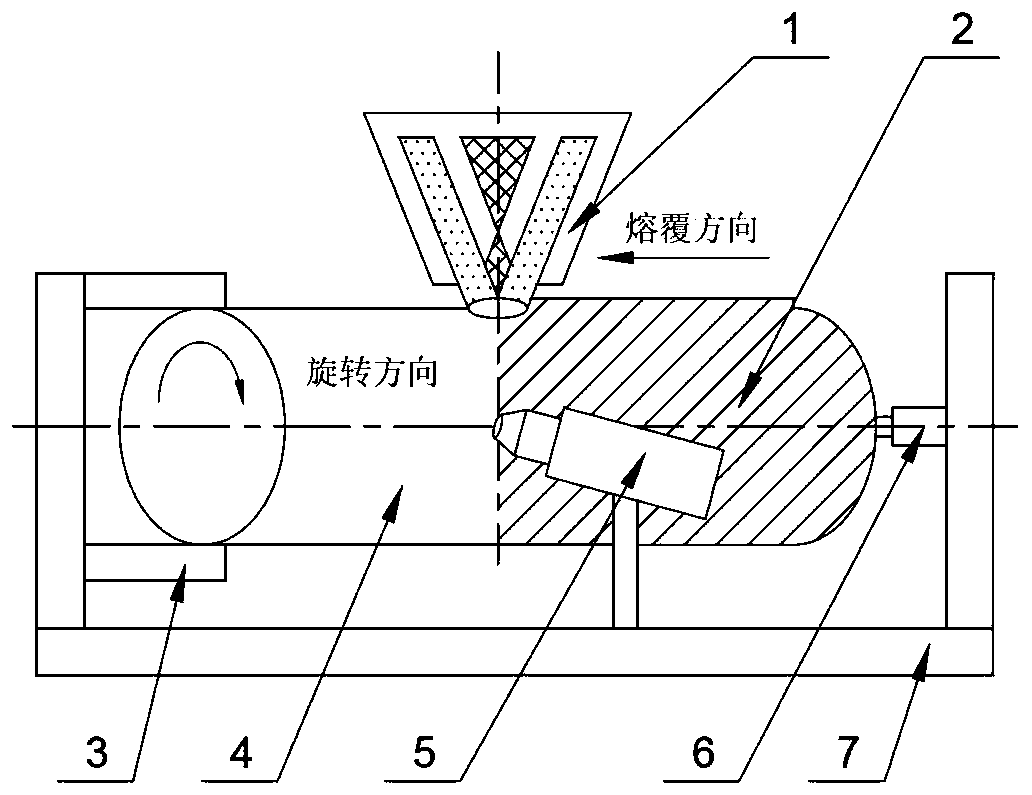

[0035] see figure 1 , during the ultra-high-speed laser cladding process for 27SiMn steel shaft workpieces, use ultrasonic impact equipment to mechanically impact the cladding layer online, the specific steps are as follows:

[0036] Step 1, put the shaft workpiece 4 into the chuck 3, move the top 6 to tighten the workpiece 4 and clamp the chuck 3; use an angle grinder to remove stains and rust on the surface of the workpiece, and then wipe the surface of the workpiece 4 with alcohol;

[0037] Step 2, select JG-8 iron-based self-fluxing powder, the particle size range of the cladding powder is 20μm~53μm, the sphericity is ≥90%, the preheating temperature is 120°C, the holding time is 1h, and then the powder is sieved with a 200-mesh sieve before loading into the powder feeder;

[0038] Step 3. Adjust the parameters of the ultra-high-speed laser cladding equipment. The laser cladding power is 3KW, and the spot size is Φ2mm; the working distance of the spot from the cladding he...

Embodiment 2

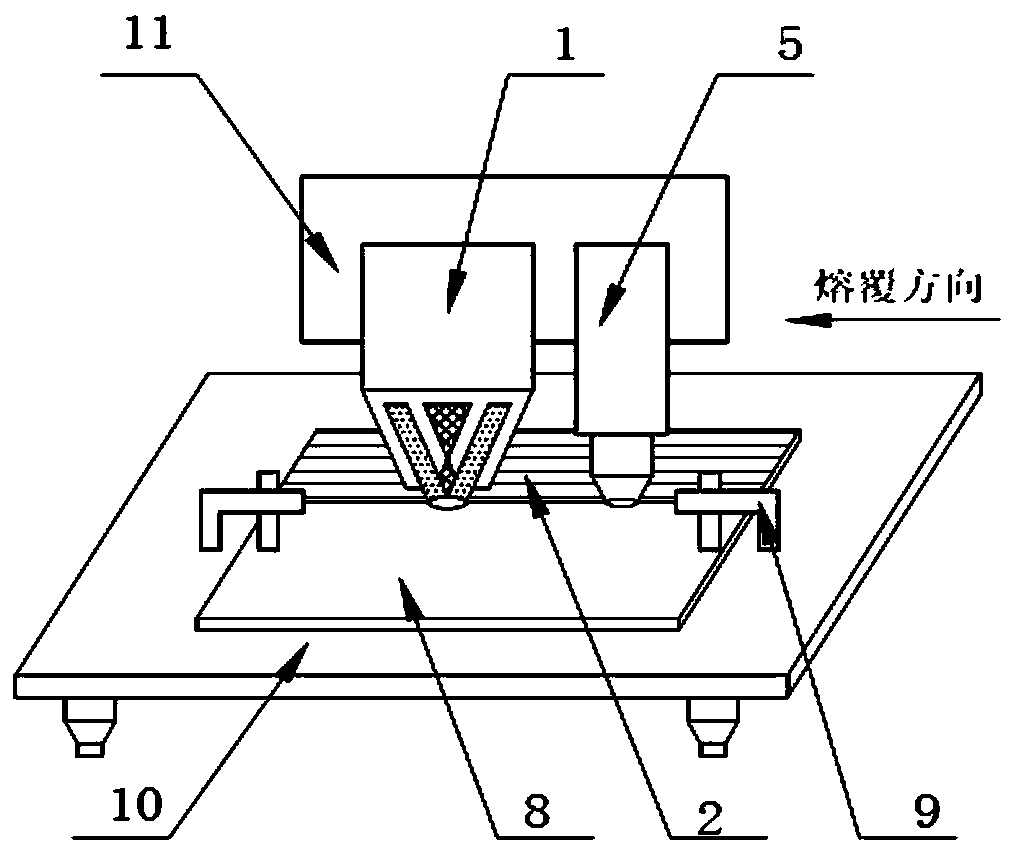

[0046] see figure 2 , during the ultra-high-speed laser cladding process for plate workpieces, use ultrasonic impact equipment to mechanically impact the cladding layer online, the specific steps are as follows:

[0047] Step 1, fix the 45 steel plate workpiece 8 on the working platform 10 through the fixing fixture 9; use an angle grinder to remove stains and rust on the surface of the workpiece, and then wipe the surface of the workpiece 8 with alcohol;

[0048] Step 2: Select Ni30 self-fluxing powder, the particle size range of the cladding powder is 20μm~53μm, the sphericity is ≥90%, the preheating temperature is 120°C, the holding time is 1h, and then the powder is sieved with a 200-mesh sieve and loaded into the powder feeder middle;

[0049] Step 3. Adjust the parameters of the ultra-high-speed laser cladding equipment. The laser cladding power is 1KW-2KW, and the spot size is Φ1mm; the working distance of the spot from the cladding head to the workpiece is 14mm; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com