A penetrant flaw detection process

A technology of penetrant flaw detection and technology, which is applied in the field of mold production and processing, can solve the problems of low efficiency of flaw detection and detection, and achieve the effects of improving flaw detection and detection efficiency, saving time, and improving color sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

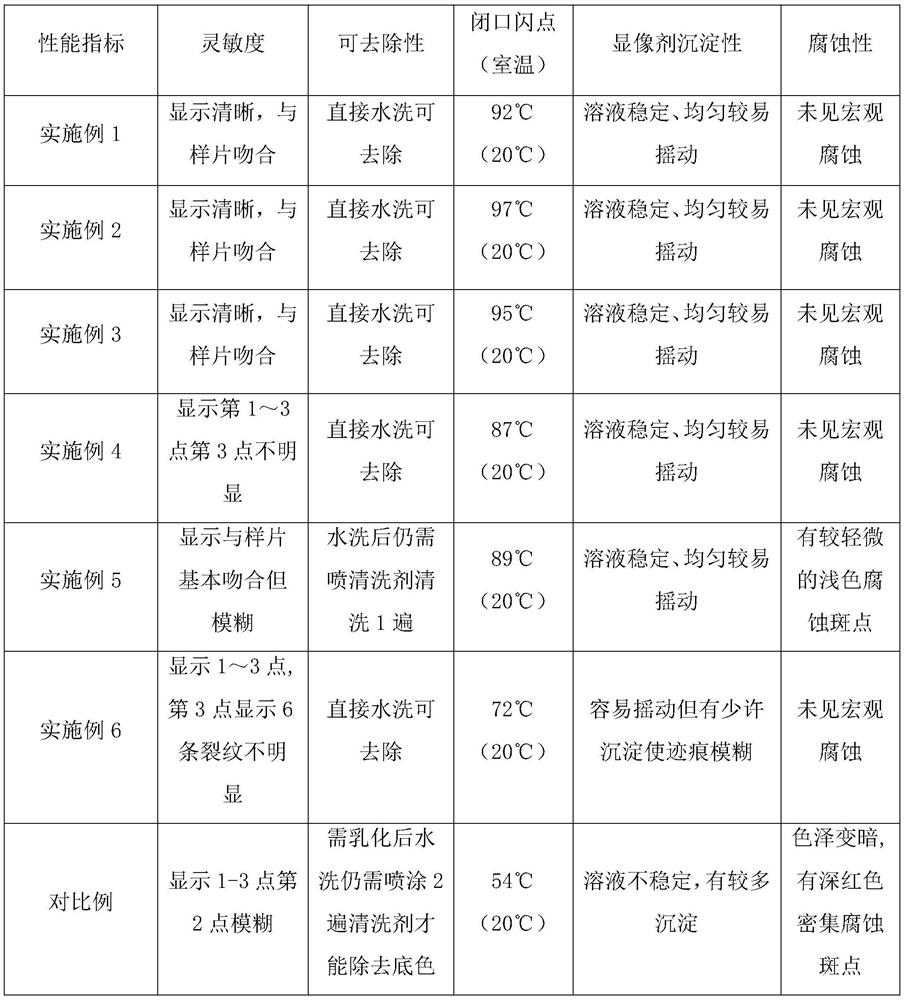

Examples

Embodiment 1

[0029] Using the penetrant flaw detection agent prepared above to carry out the penetrant flaw detection process operation, the steps are:

[0030] S1 prepares the penetrating flaw detection agent according to the method of the present invention, and the specific operation is: a, prepare the penetrating agent: add 100 parts of water, 2 parts of rose bengal, 1 part of potassium hydroxide, 5 parts of hydroxypropyl starch phosphate, 2 parts of triethanolamine, fully stirred at room temperature to dissolve all of them to obtain the penetrating agent of the penetrant flaw detection agent; b. Preparation of emulsifier: add 10 parts of milk lark, 20 parts of distilled gasoline at 170-200 ° C, lauric acid in order by weight percentage 20 parts of isopropyl ester, 50 parts of acetone, and 20 parts of methyl benzoate are fully stirred at room temperature to make them all dissolve to obtain an emulsifier for penetrating flaw detection agent; c, preparation of imaging agent: add 100 parts ...

Embodiment 2

[0038] Using the penetrant flaw detection agent prepared above to carry out the penetrant flaw detection process operation, the steps are:

[0039] S1 prepares penetrating flaw detection agent according to the method of the present invention, concrete operation is: a, prepare penetrating agent: add 100 parts of water successively by weight percentage, rose bengal 5 parts, potassium hydroxide 5 parts, hydroxypropyl starch phosphate 10 parts, 5 parts of triethanolamine, fully stirred at room temperature to make it all dissolve to obtain the penetrating agent of the penetrant flaw detection agent; b, preparation of emulsifier: add 15 parts of milk lark, 30 parts of distilled gasoline at 170-200 ° C, lauric acid in order by weight percentage 25 parts of isopropyl ester, 55 parts of acetone, and 25 parts of methyl benzoate are fully stirred at room temperature to make them all dissolve to obtain an emulsifier for penetrant flaw detection agent; c, preparation of imaging agent: add 1...

Embodiment 3

[0047] Using the penetrant flaw detection agent prepared above to carry out the penetrant flaw detection process operation, the steps are:

[0048]S1 prepares penetrating flaw detection agent according to the method of the present invention, concrete operation is: a, prepare penetrating agent: add 100 parts of water successively by weight percentage, 3 parts of rose bengal, 3 parts of potassium hydroxide, 8 parts of hydroxypropyl starch phosphate, 3 parts of triethanolamine, fully stirred at room temperature to make it all dissolve to obtain the penetrating agent of the penetrating flaw detection agent; b. Preparation of emulsifier: add 13 parts of milk lark, 25 parts of distilled gasoline at 170-200 ° C, lauric acid in order by weight percentage 22 parts of isopropyl ester, 52 parts of acetone, and 22 parts of methyl benzoate are fully stirred at room temperature to make them all dissolve to obtain an emulsifier for penetrant flaw detection agent; c, preparation of imaging age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com