Preparation and application of ordered gas diffusion electrode based on nanotube array

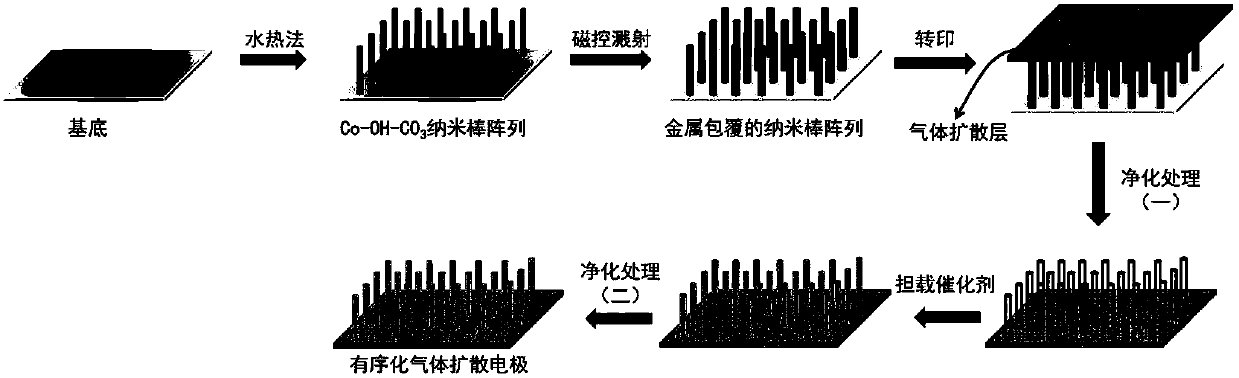

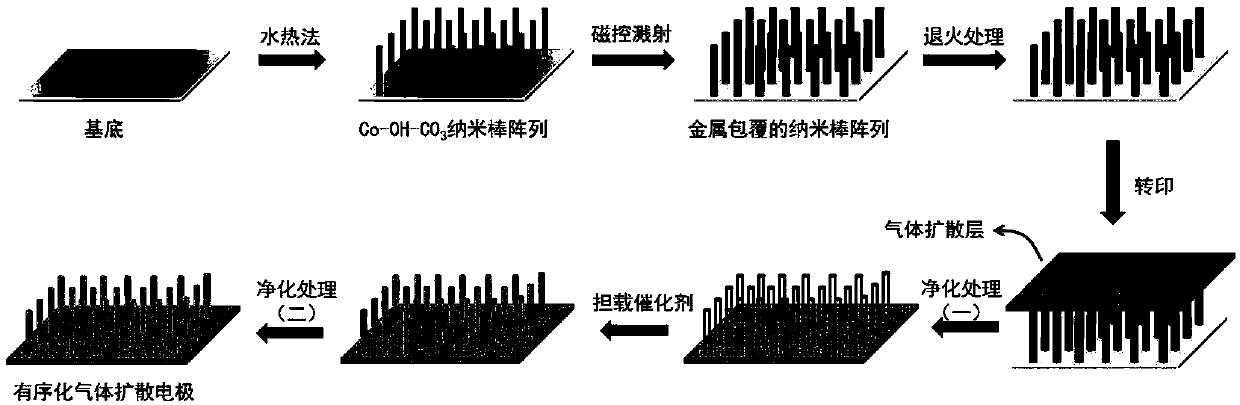

A technology of gas diffusion electrodes and nanotube arrays, applied in circuits, fuel cells, electrical components, etc., can solve the problems of disordered accumulation of catalysts, low utilization rate of catalysts, high consumption of precious metals, etc., and achieve adjustable catalyst components and preparation The effect of mild conditions and thin catalytic layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

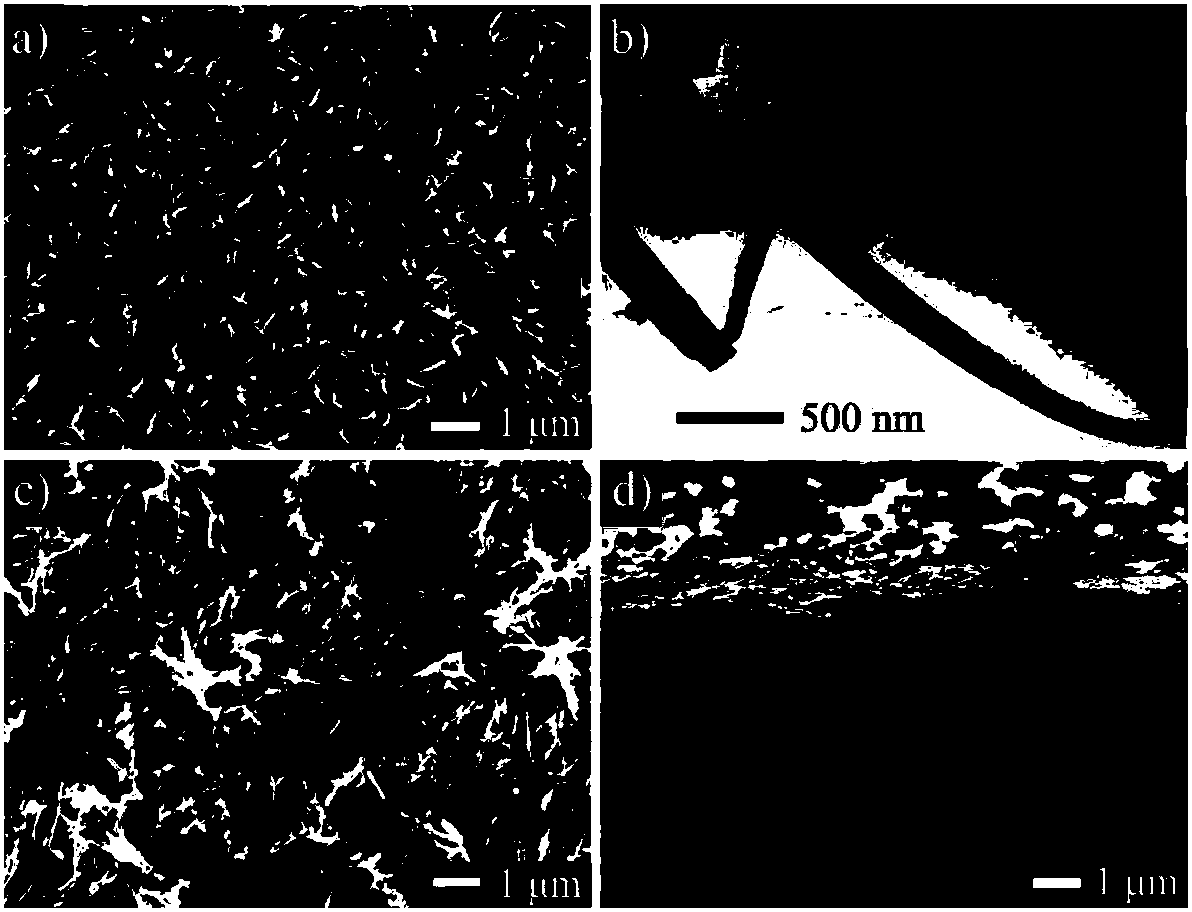

[0043] Preparation of Co-OH-CO by hydrothermal method using stainless steel as substrate 3 array. The reaction solution was 10 mM ammonium fluoride, 25 mM urea, and 5 mM cobalt nitrate. React in a high-pressure reactor at 120°C for 5 hours to prepare Co-OH-CO on the substrate 3 array. image 3 a) shows the prepared Co-OH-CO 3 SEM image of the nanorod array. It can be seen from the figure that Co-OH-CO 3 Nanorod arrays grow uniformly on the substrate, the growth direction is basically perpendicular to the substrate, the diameter is about 100nm, Co-OH-CO 3 The areal density of nanorods is 3-4e 9 / cm 2 .

[0044] Co-OH-CO was deposited by magnetron sputtering 3 Pd is carried on the array. The magnetron sputtering power is 100W, the sputtering time is 10min, and the operating pressure is 1.0Pa. image 3 b) shows the TEM image of the fabricated nanorod array. It can be seen from the figure that magnetron sputtering in Co-OH-CO 3 A uniform Pd layer is carried on the arr...

Embodiment 2

[0051] Co-OH-CO 3 Nanorod arrays, Pd@Co-OH-CO 3 Refer to Example 1 for the preparation method of the nanorod array. Co-OH-CO loaded with Pd 3 nanorod arrays at 400 °C, H 2 -Ar(5vol.%H 2 ) atmosphere annealed for 60min, during the annealing process Co-OH-CO 3 The nanorod arrays were reduced to Co nanorod arrays. Figure 5 a) shows the prepared Co-OH-CO 3 SEM image of the nanorod array. Figure 5 b) is the Pd nanorod array after annealing treatment, the annealing treatment did not destroy the order of the array, the length of the Co nanorods loaded with Pd is about 3 μm, and the diameter is about 140 nm. The Pd@Co nanorod array was transferred onto the gas diffusion layer with a microporous layer, the transfer pressure was 2 MPa, the transfer temperature was 25 °C, and the transfer time was 1 min.

[0052] Purify the gas diffusion electrode. The treatment process is as follows: put the gas diffusion electrode in 0.5M sulfuric acid solution, soak it at 80°C for 1 hour, pi...

Embodiment 3

[0057] Refer to Example 2 for the preparation method of the ordered gas diffusion electrode.

[0058] The prepared gas diffusion electrode was packaged into a membrane electrode assembly, the packaged pressure was 0.5 MPa, and the temperature was 140°C. The anode of the membrane electrode assembly uses a gas diffusion electrode, and the loading capacity of the anode Pt / C (70wt.%, Johnson Matthey) is 0.15mg cm -2 , The electrolyte membrane is a commercial alkaline anion exchange membrane (AS-4). Battery test condition: H 2 / O 2 Flow: 100 / 200sccm; battery temperature 50°C, saturated humidification, battery back pressure 0.2MPa. Figure 8 Shown is the I-V performance curve of the ordered gas diffusion electrode based on the PdCo nanotube array in the fuel cell, and the maximum output power of the cell is 161.4mWcm -2 , indicating that the prepared cells also have good performance in alkaline anion exchange membrane fuel cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com