Curdling agent and method for preparing cheese

A curdling agent and cheese technology, applied in biochemical equipment and methods, dairy products, cheese substitutes, etc., can solve the problems that curdling agents need to be developed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

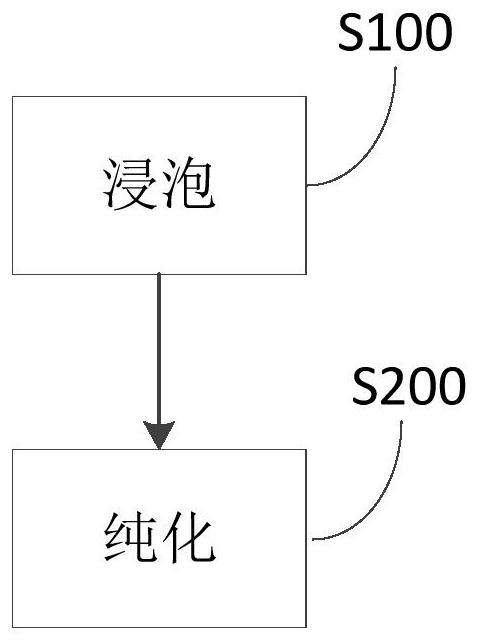

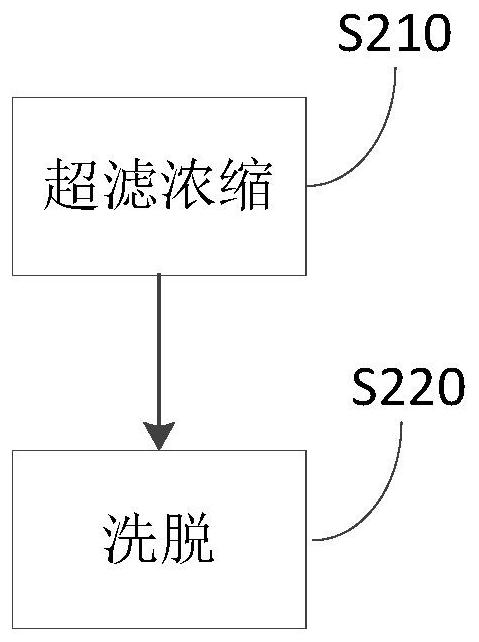

Method used

Image

Examples

Embodiment 1

[0087] In this example, the effect of different extraction conditions was studied:

[0088] Basic extraction method:

[0089] Cut the dried leaves of Qingyang ginseng with scissors, add the extract at a certain ratio of material to liquid, mix well and extract, then filter with four layers of gauze, centrifuge the filtrate at 8000g at 4°C for 40min to remove impurities, and use a 0.22μm filter membrane for the supernatant Filtration, the microfiltrate was concentrated and separated through a 10.0kD ultrafiltration tube, and the upper layer was taken to obtain the Qingyang ginseng protease concentrate. Coomassie brilliant blue method (Bradford, 1976) was used to measure the protein content of the concentrate, and 12% (w / v) skimmed reduced milk was used to observe the curdling time.

[0090] 1. Different extraction conditions

[0091] Three extraction conditions were studied, heating at 55°C for 40 minutes, standing at 25°C for 40 minutes, and standing at 4°C for 40 minutes. ...

Embodiment 2

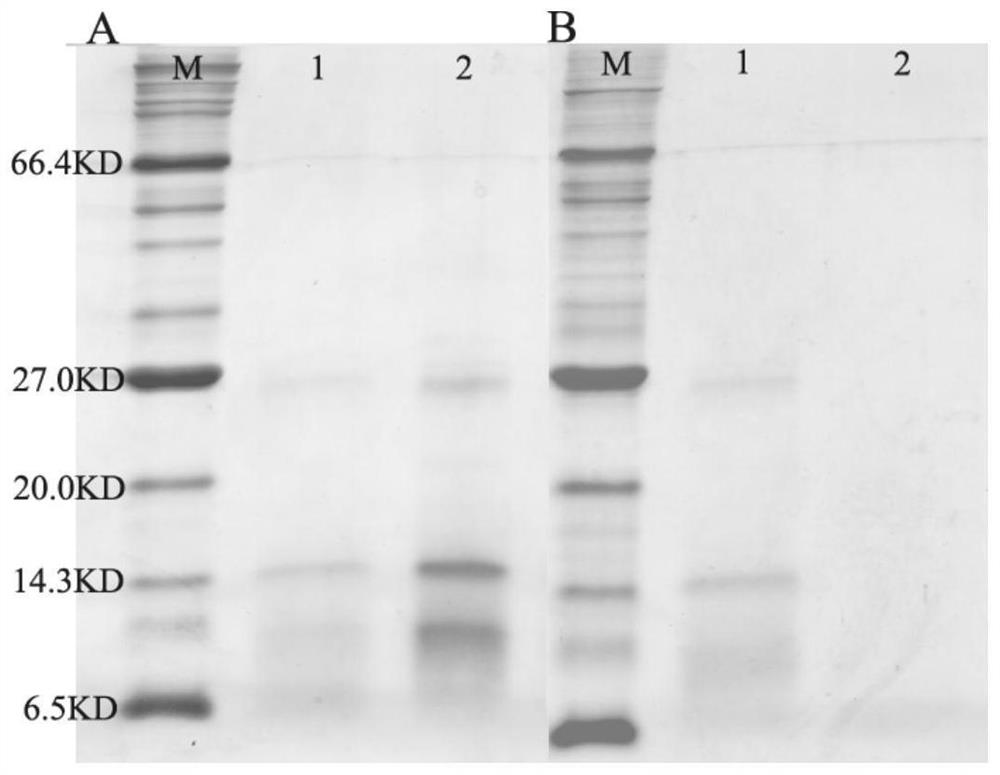

[0108] Basic properties of embodiment 2 protease QA and QC

[0109] Milk-clotting activity and hydrolytic activity are very important characteristics in the application of chymosin. The milk-clotting activity of many plant proteases that have been studied so far is considered to be a substitute for rennet in cheese production. However, plant rennet usually exhibits high hydrolytic activity and overly hydrolyzes casein, which is also the cause of bitter taste during cheese maturation. Therefore, the inventor analyzed and compared the curdling activity and hydrolysis activity of Qingyang ginseng protease QA, QC, calf rennet, bromelain, and papain, and the results are shown in Table 5. It can be drawn from the table that although the hydrolysis activity of Qingyang ginseng protease QA and QC is significantly higher than that of bromelain and papain (p<0.05), the curdling activity of QA and QC is also significantly higher than that of bromelain and papain (p<0.05). It can be cal...

Embodiment 3

[0121] Embodiment 3 enzymatic properties—the influence of hydrolytic activity

[0122] 1. pH value

[0123]The change of pH value in the system will affect the dissociation of the dissociable group in the active center of the enzyme, thereby affecting the enzyme activity. The change curves of the casein hydrolysis activities of Qingyang ginseng protease QA and QC with pH are similar to a certain extent, but when the hydrolysis activities reach the maximum value, the corresponding pHs of QA and QC are different, which are 7.0 and 6.5 ( Figure 5 ).

[0124] Depend on Figure 5 a It can be concluded that when the pH is less than 7.0, the hydrolytic activity of QA on casein is gradually enhanced; when the pH is greater than 7.0, the hydrolytic activity of QA on casein is gradually weakened; It is always higher than 40% of the maximum hydrolytic activity. This result shows that QA has casein hydrolytic activity under weakly acidic, neutral and weakly alkaline conditions.

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com