Aldehyde removing gypsum board and preparation method thereof

A gypsum board and aldehyde purification technology, which is applied in the field of building materials, can solve the problems of difficult to guarantee effect, weak adsorption, and difficult to guarantee the aldehyde purification effect of gypsum board, so as to improve adsorption efficiency, enhance adsorption pertinence, and increase formaldehyde adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

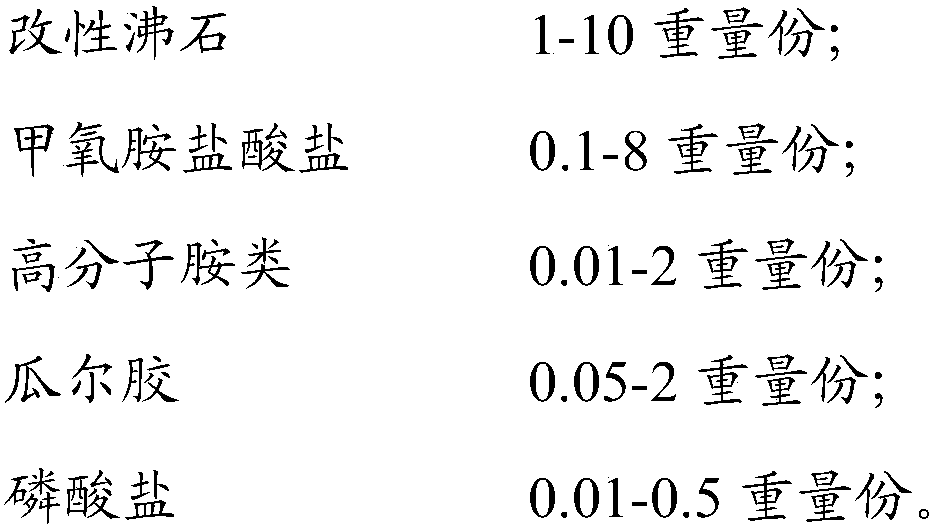

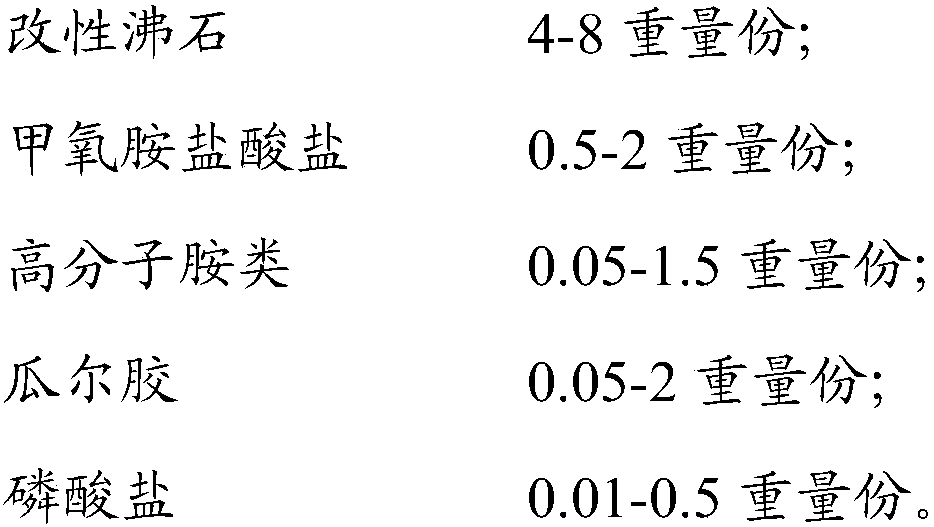

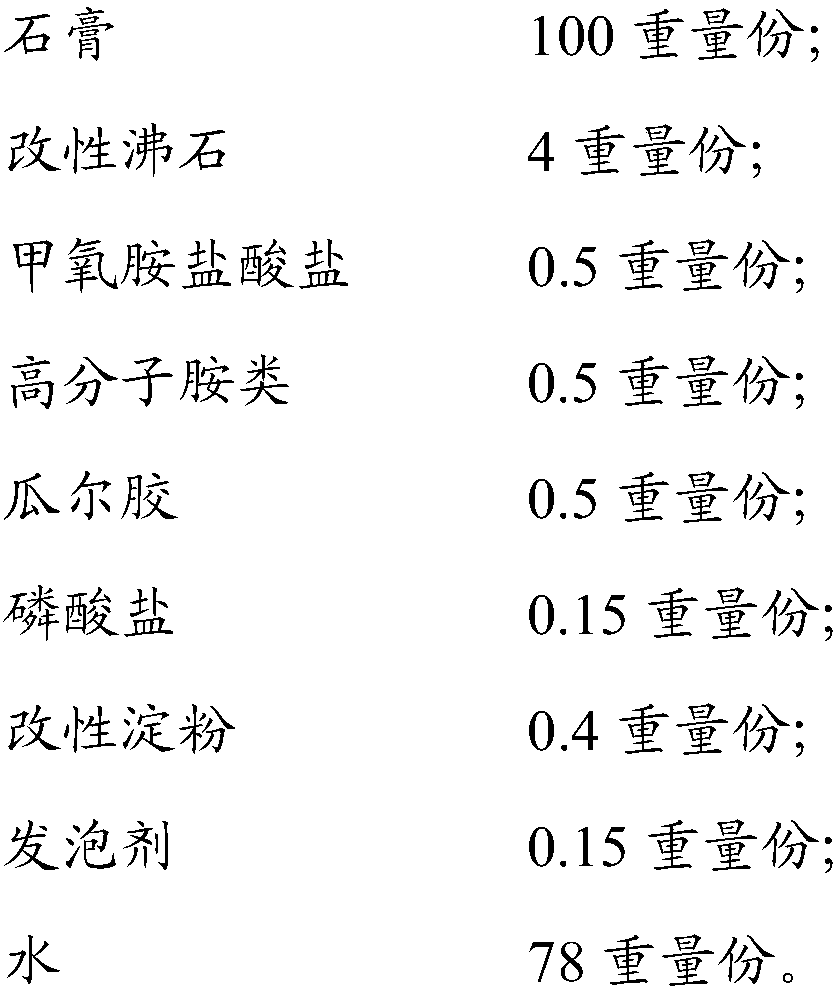

[0041] Mix 1-10 parts by weight of modified zeolite, 0.1-8 parts by weight of methoxyamine hydrochloride, 0.01-2 parts by weight of polymer amines, 0.05-2 parts by weight of guar gum and 0.01-0.5 parts by weight of phosphate The final mixture, 100 parts by weight of gypsum, 0.02-1 parts by weight of modified starch, mechanically stirred to obtain a uniform solid powder, put into the mixer; 0.05-1 parts by weight of foaming agent was added to the water, and the mixed solution passed through the foaming system After foaming, it enters the mixer; the raw materials are fully stirred by the mixer to obtain a uniform slurry, which is continuously poured between the protective papers and extruded to obtain a wet gypsum board; the wet gypsum board is solidified, cut, and dried 1. After sawing the edge, the net aldehyde gypsum board is made.

[0042] Table 1 lists the data of some examples of the present invention. It should be noted that the data in Table 1 are part of the selected d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com